a negative ion additive

A technology of negative ion additive and molecular sieve, applied in coating, textile and paper making, polyurea/polyurethane coating, etc., can solve the problem of unfavorable negative ion powder properties, large difference in surface properties between tourmaline powder and high molecular polymer, difficult to uniformly disperse and stabilize There are other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

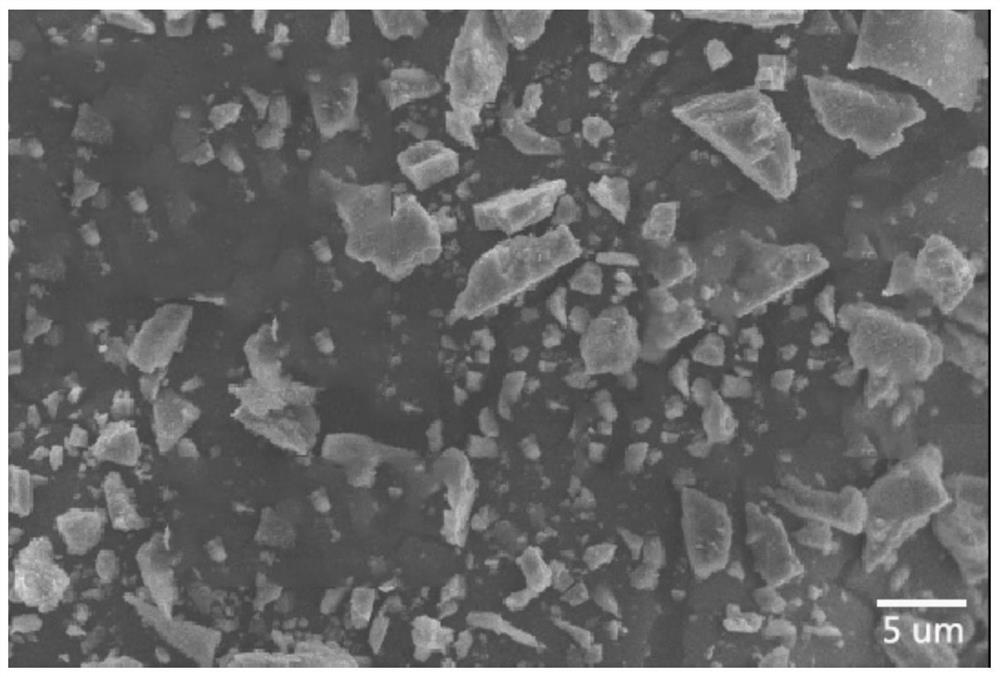

[0020] a) By mechanical shearing, the tourmaline is made into a powder A with a particle size of 6-20 microns (such as figure 2 shown);

[0021] b) Mix sodium metaaluminate, sodium hydroxide, sodium silicate, and water according to the following molar ratios, SiO 2 :Al 2 o 3 =3~5:1、Na 2 O:SiO 2 =1~1.5:1 and H 2 O:Na 2 O=35~65:1, get Sol B after mixing evenly;

[0022] c) Powder A is added to sol B, the mass ratio is A:B=3~5%, after continuing to stir evenly, stand at room temperature for 3~8h;

[0023] d) Put it into a polytetrafluoroethylene-lined stainless steel reaction kettle, and let it stand at 98±2°C for 5 to 14 hours;

[0024] e) The product was washed with deionized water, filtered, and dried to obtain a tourmaline@13X molecular sieve composite material.

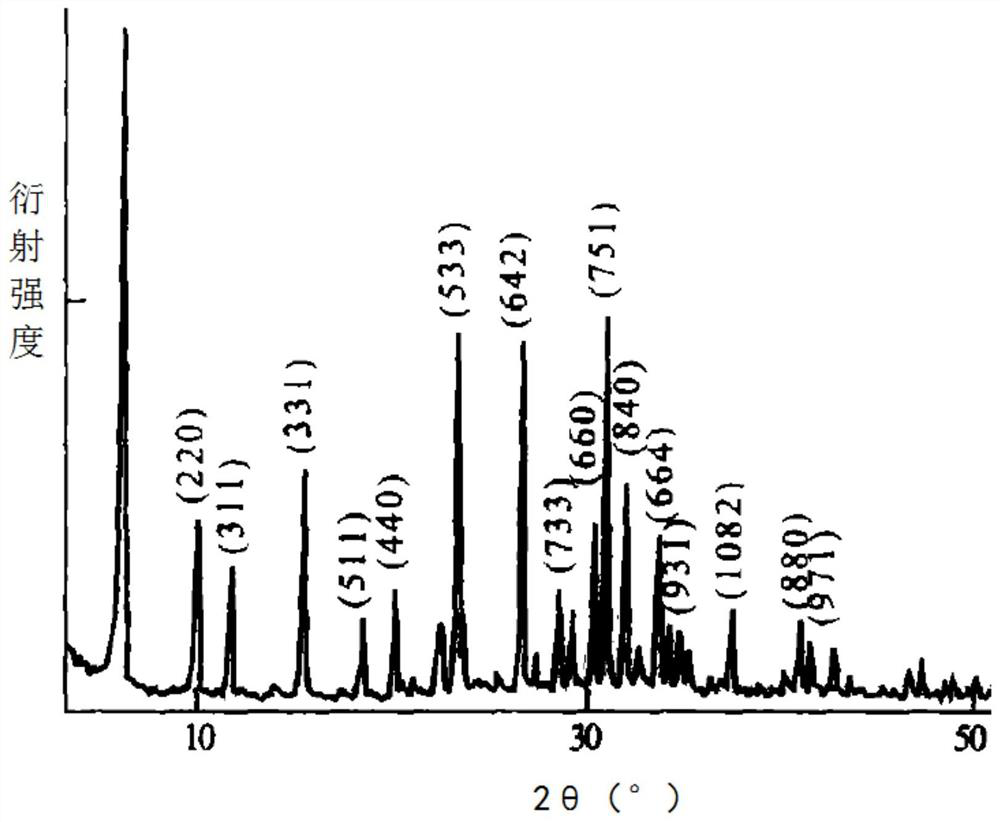

[0025] like figure 1 As shown, the diffraction peaks of tourmaline@13X molecular sieve composites correspond to tourmaline and 13X molecular sieve respectively.

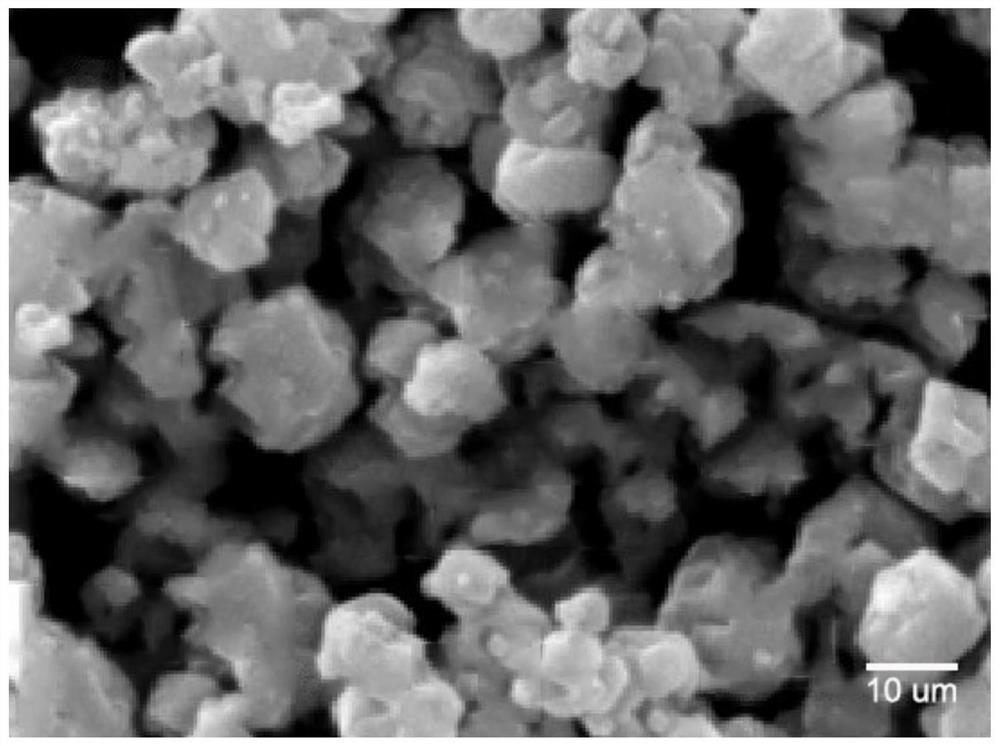

[0026] like image 3 Shown is the SEM p...

Embodiment 2

[0028] Add polyester polyol (PEA) or polyether polyol (PTMG) or a mixture of the two in a certain proportion to a three-necked bottle equipped with a stirrer and a thermometer, add 150°C, and vacuum dry for 9 hours. The tourmaline@13X molecular sieve composite material prepared in Example 1 was dehydrated for 2 to 3 hours at a vacuum degree of 0.09MPa and a temperature of about 120°C by starting the vacuum pump and agitator. When the temperature is lowered to 40°C, add the measured amount of TDI, stir, slowly raise the temperature to 80°C, keep the temperature at 80-85°C for 2 hours, and then place it at room temperature for 4-5 hours to fully react with TDI, then vacuum defoam for 0.5 hours or so, to prepare a prepolymer, then add a measured amount of chain-extending cross-linking agent 3,3'-dichloro-4,4'-diaminodiphenylmethane (MOCA), stir evenly, and pour it into a preheated mold Vulcanize on a flat vulcanizer at 120°C for 10 minutes, and after demoulding, cure at 100°C for...

Embodiment 3

[0033] A kind of surface layer slurry of negative ion polyurethane resin for leather, according to the following components by mass parts composition:

[0034] Waterborne polyurethane resin (Covestro: Bayhydrol A 2601): 100 parts

[0035] Water: 20-40 parts

[0036] Water-based ink (BASF: Joncryl 678): 10-30 parts

[0037] Negative ion additive (ie tourmaline@13X molecular sieve composite material): 3-5 parts.

[0038] The negative ion polyurethane resin surface layer slurry of the present invention is compounded on the base cloth by dry veneering process, the speed is 8m / min, the surface layer thickness is 100μm, and the oven temperature is 102°C; the obtained negative ion polyurethane leather has a high surface quality. No defects, mechanical properties such as breaking strength and elongation at break remain unchanged (as shown in the table below), and the amount of negative ions emitted is ≥3000 / cm 3 .

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com