Green and efficient preparation method for aqueous phase iron oxide nanoparticles

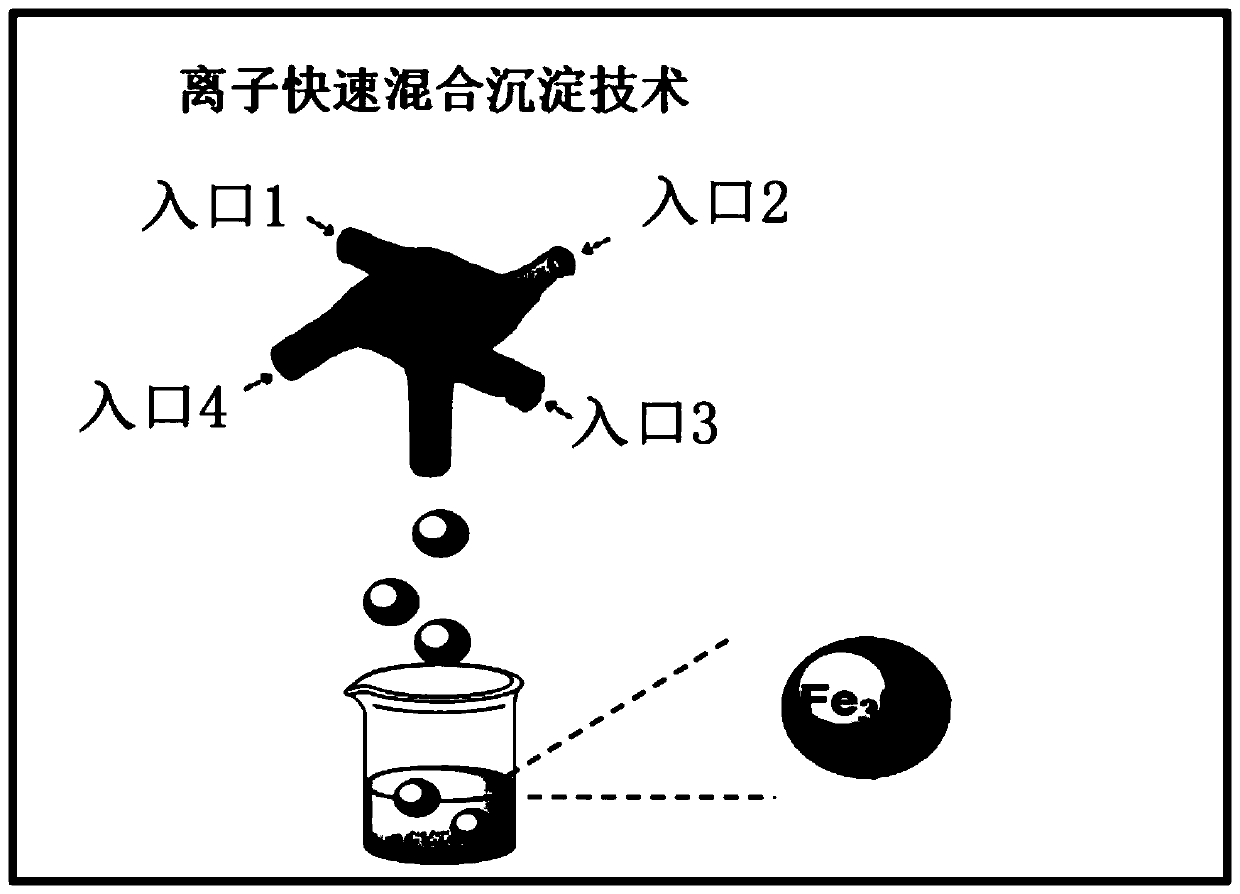

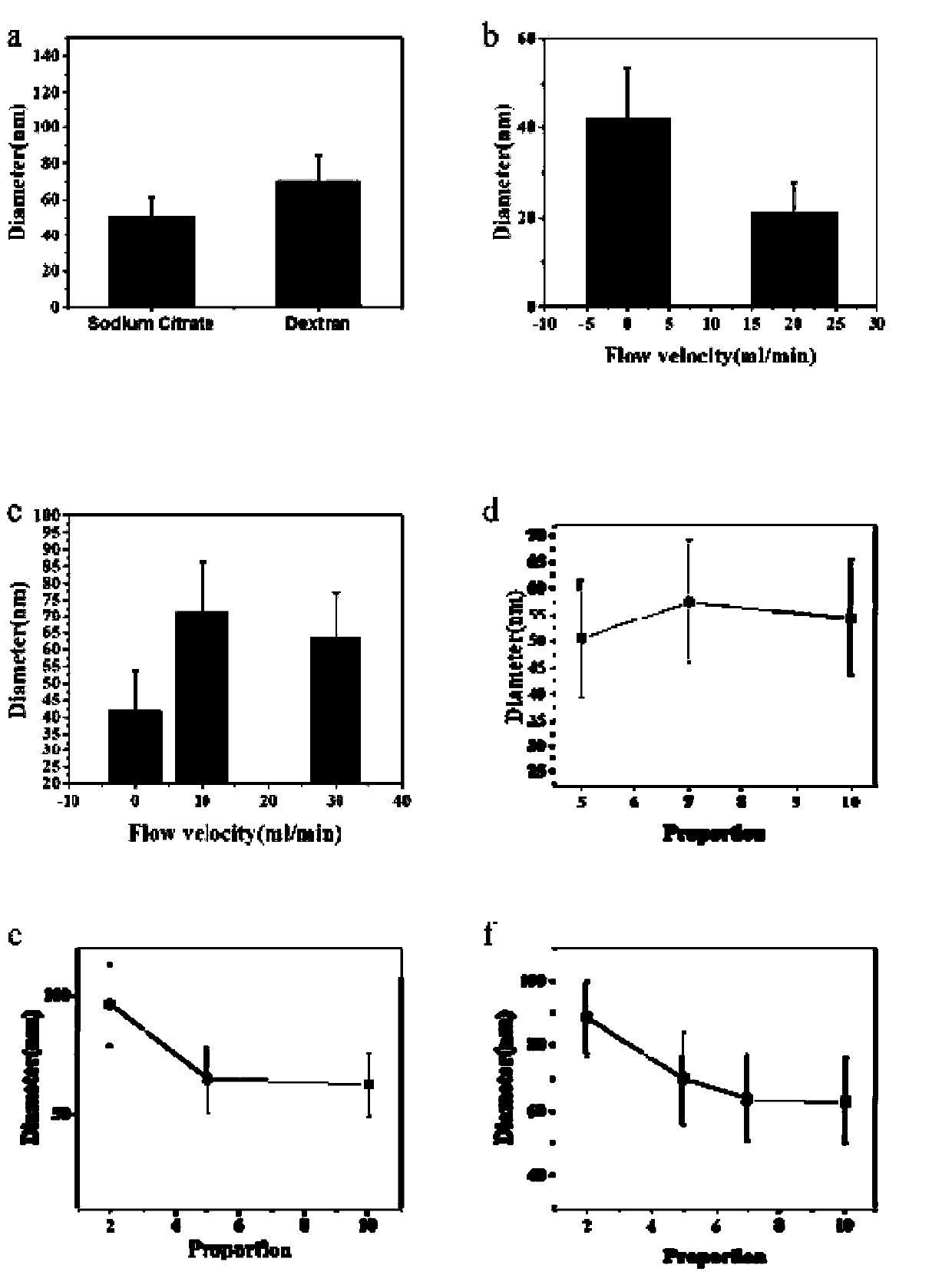

A technology of iron oxide nanoparticles and particles, which is applied in the direction of iron oxide/hydroxide, nanotechnology, ferrous iron oxides, etc. It can solve the problems that cannot be directly used in water-phase biomedicine, difficult to effectively control, large particles, etc. Achieving good particle size distribution and stability, avoiding uneven mixing of reagents, and simple and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Prepare 30mL FeCl 3 The concentration is 0.12mol / L, FeCl 2 The concentration is 0.08mol / L solution A;

[0048] (2) Dissolve 0.950 g of sodium citrate dihydrate in 15 mL of distilled water to prepare solution B;

[0049] (3) Prepare 15 mL of ammonia solution with a volume fraction of 10% as solution C;

[0050] (4) Use the FNC device to mix the solutions evenly, wherein solution A passes through inlets 1 and 3, solution B passes through inlet 2, and solution C passes through inlet 4, and the flow rate is adjusted to 25mL / min;

[0051] (5) Ice-bathed for 30 minutes, after the temperature of the solution was raised to room temperature, heated at 80-85°C for 40 minutes to obtain a cloudy solution D;

[0052] (6) Solution D was centrifuged at 8000rpm for 5min, the supernatant was taken, precipitated with acetone, centrifuged at 8000rpm for 5min, the precipitate was dissolved in distilled water to obtain aqueous phase iron oxide nanoparticles, and this sample was named...

Embodiment 2

[0054] (1) Prepare 30mLFeCl 3 The concentration is 0.12mol / L, FeCl 2 The concentration is 0.08mol / L solution A;

[0055] (2) Dissolve 0.875g of dextran in 15mL of distilled water to prepare solution B;

[0056] (3) Prepare 15 mL of ammonia solution with a volume fraction of 10% as solution C;

[0057] (4) Use the FNC device to mix the solutions evenly, wherein solution A passes through inlets 1 and 3, solution B passes through inlet 2, and solution C passes through inlet 4, and the flow rate is adjusted to 25mL / min;

[0058] (5) Ice-bathed for 30 minutes, after the temperature of the solution was raised to room temperature, heated at 80-85°C for 40 minutes to obtain a cloudy solution D;

[0059] (6) Solution D was centrifuged at 8000rpm for 5min, the supernatant was taken, precipitated with acetone, centrifuged at 8000rmp for 5min, the precipitate was dissolved in distilled water to obtain aqueous iron oxide nanoparticles, and this sample was named sample 2.

Embodiment 3

[0061] (1) Prepare 20mL FeCl 3 The concentration is 0.12mol / L, FeCl 2 The concentration is 0.08mol / L solution A;

[0062] (2) Dissolve 0.887g of sodium citrate dihydrate in 10mL of distilled water to prepare solution B;

[0063] (3) preparing 10 mL of ammonia solution with a volume fraction of 10% is solution C;

[0064] (4) Use the FNC device to mix the solutions evenly, wherein solution A passes through inlets 1 and 3, solution B passes through inlet 2, and solution C passes through inlet 4, and the flow rate is adjusted to 25mL / min;

[0065] (5) Ice-bathed for 30 minutes, after the temperature of the solution was raised to room temperature, heated at 80-85°C for 40 minutes to obtain a cloudy solution D;

[0066] (6) Solution D was centrifuged at 8000rpm for 5min, the supernatant was taken, precipitated with acetone, centrifuged at 8000rpm for 5min, the precipitate was dissolved in distilled water to obtain aqueous iron oxide nanoparticles, and this sample was named as sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com