A kind of pickering emulsion that utilizes ginkgo husk cellulose to stabilize and preparation method thereof

A technology of cellulose and ginkgo husk, which is applied in the direction of emulsion transportation, pulping with inorganic alkali, chemical instruments and methods, etc., can solve the problems that cannot be applied in the field of food, and achieve good storage stability and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Preparation of High Aspect Ratio Cellulose Nanocrystals and Pickering Emulsion

[0040] Mix the crushed ginkgo shell and the preheated 4wt% sodium hydroxide solution according to the ratio of material to liquid 1:20 (w / v), then heat in a water bath at 90°C for 2h, filter, and wash with deionized water for 4 and then dried with hot air at 50°C, then the dried cellulose was mixed with the rinsing liquid at a ratio of 1:30 (w / v) to the material and liquid, heated in a water bath at 80°C for 2 hours, and then filtered to remove the rinsing liquid. Dry with hot air at 50°C.

[0041] Then the dry cellulose powder is mixed with the preheated mass concentration of 64% sulfuric acid solution for hydrolysis reaction, the hydrolysis temperature is 45°C, the hydrolysis reaction time is 30min, and the solid-liquid ratio of cellulose and sulfuric acid solution is 1:15 (w / v), terminate the reaction with 10 times the volume of deionized water immediately after the hydrolysi...

Embodiment 2

[0045] Example 2 Using different homogeneous pressures to obtain cellulose nanocrystals with different particle sizes

[0046] To prepare cellulose nanocrystals, change the homogenization pressure on the cellulose nanocrystal suspension on the basis of Example 1, and circulate the homogenization 4 times at 0MPa, 10MPa, 30MPa, 50MPa, and 70MPa respectively. Other preparation conditions are the same as those in the examples 1 is the same. The length and diameter of CNCs under different homogeneous pressures were measured by Zetasizer ZEN3600 and atomic force microscope, and the aspect ratio of cellulose nanocrystals was calculated. Table 1 shows the length, diameter and aspect ratio of cellulose crystals after different homogenization pressures. It can be seen from Table 1 that with the increase of homogenization pressure, the diameter is less affected, while the length of CNCs is significantly reduced. Changed the aspect ratio of CNCs from 51 to 8.

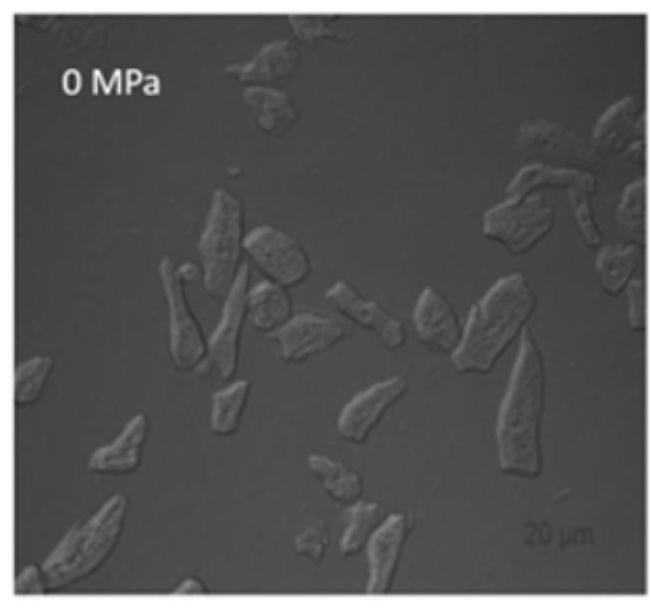

[0047] Optical microscope...

Embodiment 3

[0050] Example 3 Preparation of cellulose nanocrystals under different hydrolysis times

[0051] To prepare cellulose nanocrystals, on the basis of Example 1, the hydrolysis time was changed to 0min, 10min, 30min, 60min, and 90min, and other preparation conditions were the same as in Example 1. After the reaction, the CNCs yield was calculated, and it was calculated that the CNCs yield of hydrolyzed for 30 min was 67%, the yield of CNCs hydrolyzed for 60 min was 50%, and the yield of CNCs hydrolyzed for 90 min was 42%.

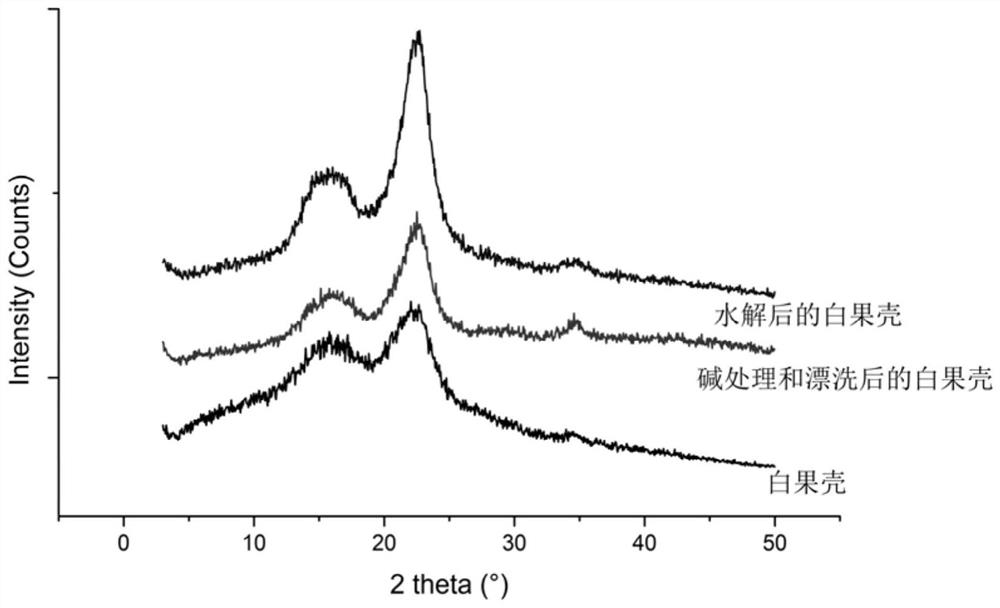

[0052] Figure 4 It is the XRD pattern of different hydrolysis time of ginkgo shell cellulose, by Figure 4 It can be seen from the figure that when the hydrolysis time is 0 min, there are obvious peaks at 16.5°, 22.0° and 34.5°, indicating that the cellulose from the husk is cellulose I. When the hydrolysis time increased for 30 minutes, the peak at 22.0° gradually increased, and when the hydrolysis time exceeded 30 minutes, the peak at 22.0° decreased agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com