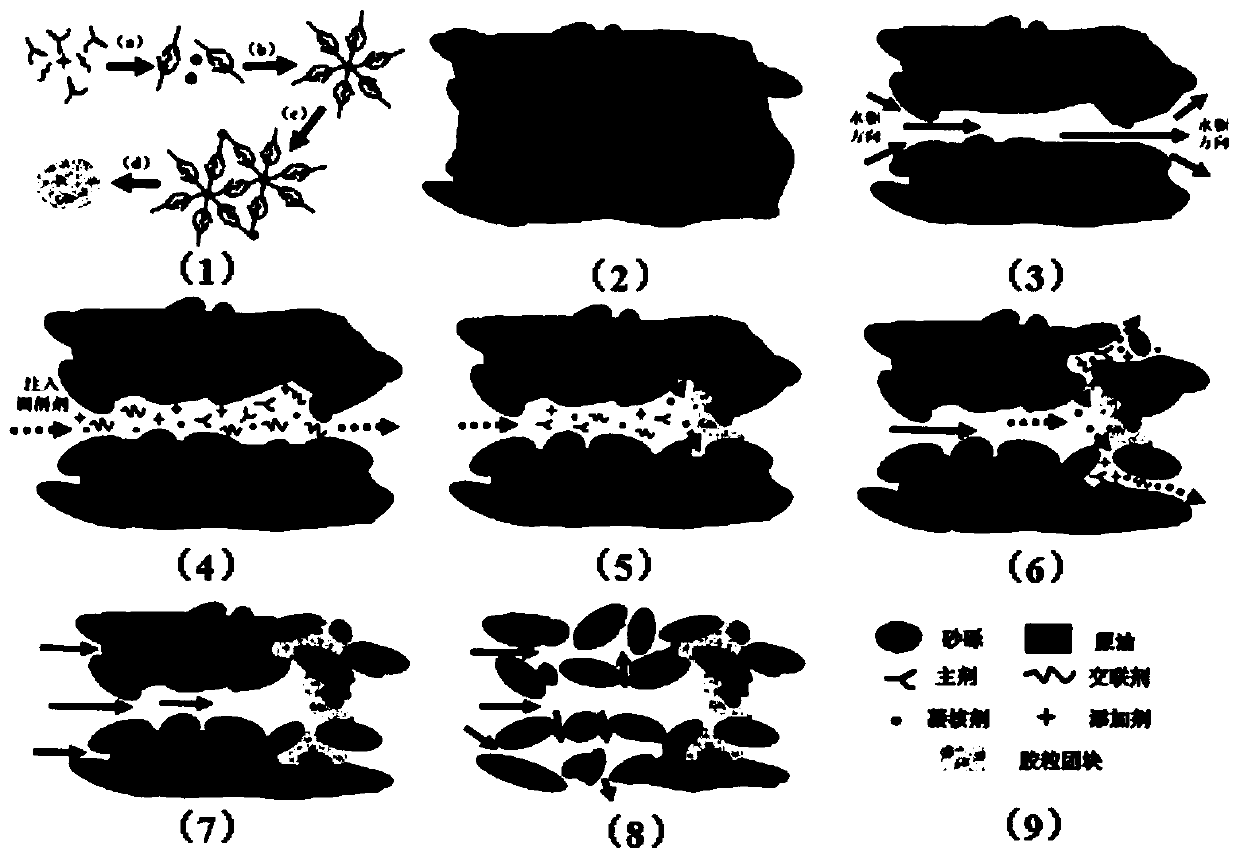

Particulate profile control agent self-adaptive to pore throat size of stratum and preparation method for particulate profile control agent

A profile control agent and self-adaptive technology, applied in the field of granular profile control agent and its preparation, can solve the problems of weak plugging ability of large pores, low gelling strength, poor injectability, etc. The effect of simple process and low requirements for pumping equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

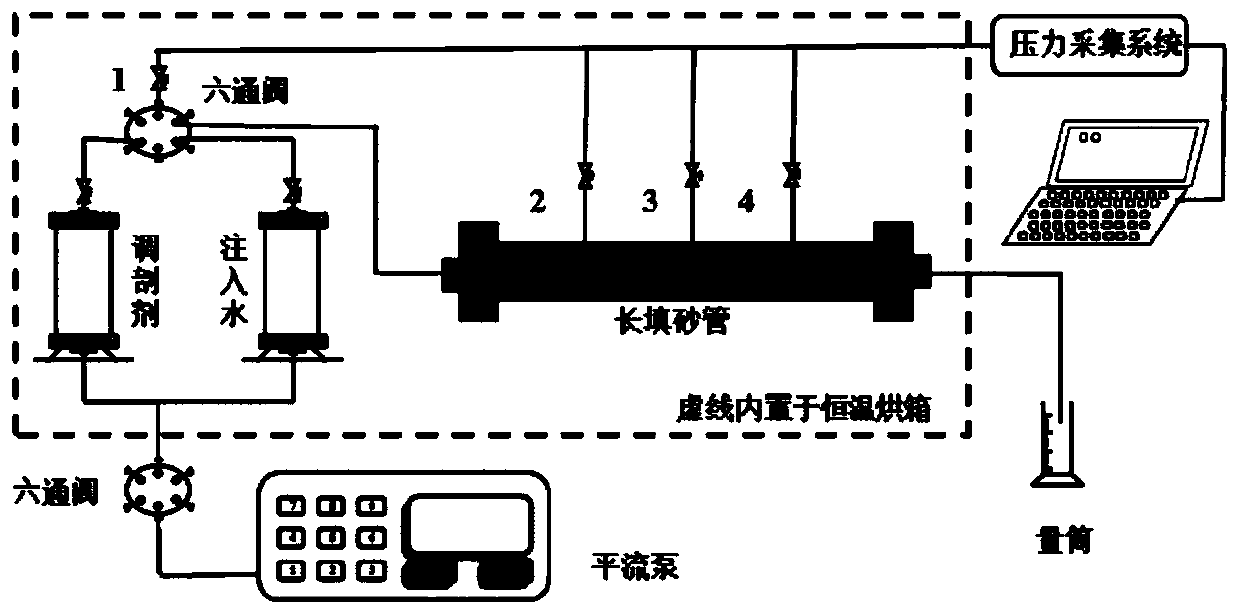

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a particle profile control agent adaptive to the formation pore throat size, the preparation raw materials of the profile control agent in mass percentage include:

[0046] Main agent: 0.12% polyacrylamide (molecular weight 10 million);

[0047] Nucleating agent: 0.005% sodium benzoate;

[0048] Cross-linking agent: 0.01% aluminum citrate;

[0049] Additive: 0.005% thiourea;

[0050] The rest is water.

[0051] Weigh the corresponding medicine according to the ratio of the above raw materials, and set the stirring speed to 150rpm, slowly add polyacrylamide to the stirring water in turn, after the polyacrylamide is fully dissolved and dispersed, then add sodium benzoate and aluminum citrate in sequence and thiourea, and continue to stir until they are evenly mixed to obtain the target profile control agent.

Embodiment 2

[0053] This embodiment provides a particle profile control agent adaptive to the formation pore throat size, the preparation raw materials of the profile control agent in mass percentage include:

[0054] Main agent: 0.15% polyacrylamide (molecular weight 8 million);

[0055] Nucleating agent: 0.008% nano silicon dioxide;

[0056] Crosslinking agent: 0.02% water-soluble phenolic resin;

[0057] Additive: 0.005% hydrazine;

[0058] The rest is water.

[0059] First, use clear water and sodium chloride to prepare simulated water with a salinity of 100,000mg / L; then weigh the corresponding medicine according to the above raw material ratio, and set the stirring speed at 250rpm, and slowly add polyacrylamide to the stirred simulated water After the polyacrylamide is fully dissolved and dispersed, add hydrazine, water-soluble phenolic resin, and nano-silicon dioxide in sequence, and continue to stir until the mixture is uniform, and the target profile control agent is obtained. ...

Embodiment 3

[0061] This embodiment provides a new type of colloidal particle profile control agent that is adaptive to the size of formation pore throats. The raw materials for the preparation of the profile control agent in terms of mass percentage include:

[0062] Main agent: 0.15% polyacrylamide (molecular weight 12 million);

[0063] Nucleating agent: 0.008% talc;

[0064] Crosslinking agent: 0.015% hexamethylenetetramine;

[0065] Additive: 0.005% sodium thiosulfate;

[0066] The rest is water.

[0067] First, clean water and sodium chloride are used to prepare simulated water with a salinity of 100,000mg / L; then the corresponding drugs are weighed according to the above raw material ratios, and the stirring speed is set to 300rpm, and polyacrylamide is slowly added to the stirred simulated water. In water; after the polyacrylamide is fully dissolved and dispersed, add sodium thiosulfate, hexamethylenetetramine, and talcum powder in sequence, and continue stirring until the mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com