Composite process method for preparing intravascular stent

A vascular stent and composite technology technology, which is applied in medical science, filament/thread forming, electrospinning, etc., can solve the problems of limited source of autologous blood vessels, difficult to meet the performance requirements of vascular stents, and expensive allogeneic decellularization technology. , to achieve the effect of accelerating endothelialization, favorable adsorption and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A composite process method for preparing vascular stents, comprising the following steps:

[0039] a. Dissolve PLCL and PEG in a mixed solution of calcium chloride and N,N-dimethylformamide with a volume ratio of 1:1 according to the mass ratio of 5:1, and prepare a 150 mg / mL solution as the oil phase, and add The endothelial growth factor trimethylated chitosan is used as the water phase, the oil phase and the water phase are fully mixed at a ratio of 10:1, and stirred until a stable water-emulsion solution is prepared.

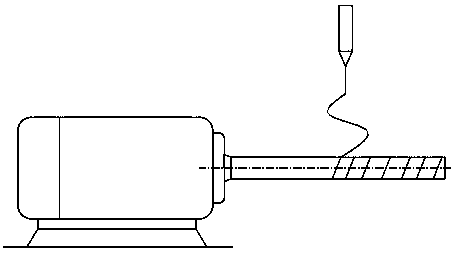

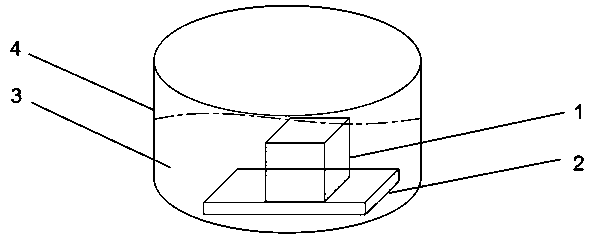

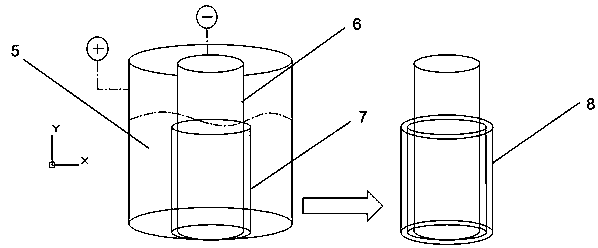

[0040] b. Load the water-emulsion solution in a into the cylinder for electrospinning, such as figure 1 As shown, a 316L stainless steel solid electrode rod with a diameter of 2.5 cm is used as a receiving rod to collect electrospinning, and the receiving range length of the receiving rod to receive electrospinning on the shaft is 7 mm, wherein the distance between the receiving rod and the needle The voltage was 10kv, the injection speed was 0.8mL / h...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, a composite process method for preparing a vascular stent, comprising the following steps:

[0047] a. Dissolve PLCL and PEG in a mixed solution of calcium chloride and N,N-dimethylformamide with a volume ratio of 1:1 according to the mass ratio of 7:1, and prepare a 250mg / mL solution as the oil phase, and add Endothelial growth factor trimethylated chitosan is used as the water phase, the oil phase and the water phase are fully mixed at a ratio of 15:1, and stirred until a stable water-emulsion solution is prepared.

[0048] b. Load the water-emulsion solution in a into the barrel for electrospinning, use a 316L stainless steel solid electrode rod with a diameter of 2.5cm as the receiving rod to collect the electrospinning, and control the receiving rod to receive the electrospinning on the shaft The length of the receiving range is 8mm, the voltage between the receiving rod and the needle is 10kv, the injection sp...

Embodiment 3

[0054] This embodiment is basically the same as Embodiment 1, a composite process method for preparing a vascular stent, comprising the following steps:

[0055] a. Dissolve PLCL and PEG in a mixed solution of calcium chloride and N,N-dimethylformamide with a volume ratio of 1:1 according to the mass ratio of 10:1, and prepare a 350 mg / mL solution as the oil phase. The endothelial growth factor trimethylated chitosan is used as the water phase, the oil phase and the water phase are fully mixed at a ratio of 20:1, and stirred until a stable water-emulsion solution is prepared.

[0056] b. Load the water-emulsion solution in a into the barrel for electrospinning, use a 3cm diameter 316L stainless steel solid electrode rod as a receiving rod to collect the electrospinning, and control the receiving rod to receive the electrospinning on the shaft The length of the receiving range is 9mm, the voltage between the receiving rod and the needle is 15kv, the injection speed is 1.2mL / h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com