Cefalexin capsules and preparation method

A technology of cephalexin capsules and cephalexin, applied in capsule delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of unstable dissolution of cephalexin capsules and poor product fluidity, and improve fluidity and dissolution Unstable problems, improvement of fluidity, effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

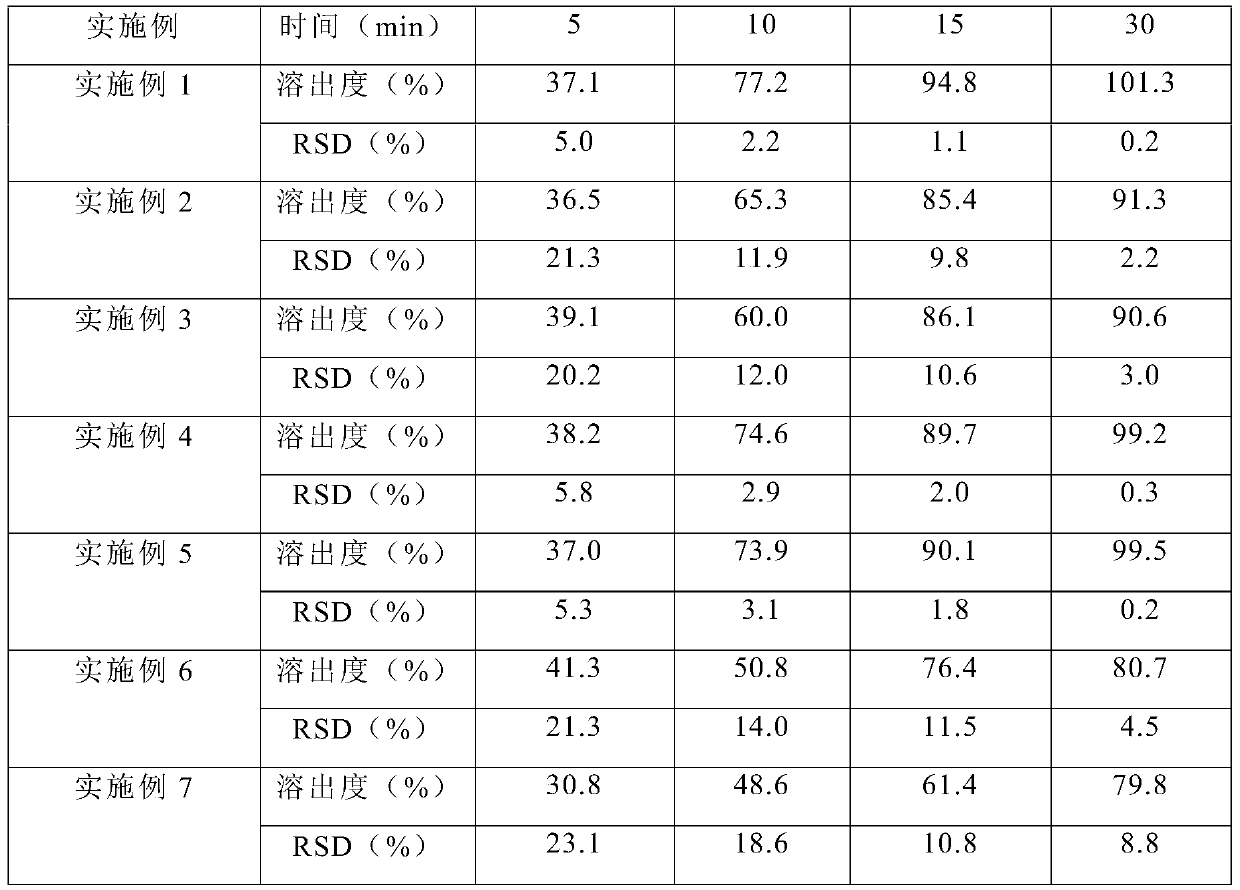

Embodiment 1

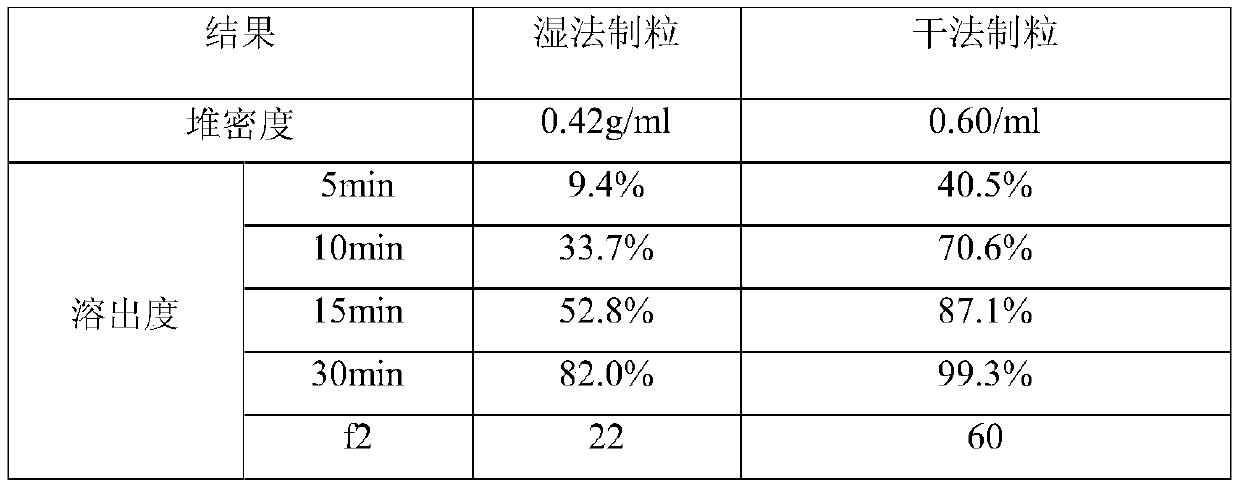

[0038] A preparation method of cephalexin capsules comprises:

[0039] Step S1, pre-mixing: put 90.6% of cephalexin, 7.9% of microcrystalline cellulose, and 1.0% of carmellose sodium (here is weight percentage) into the three-dimensional motion mixer, and set the frequency of the three-dimensional motion mixer to 10Hz , mixed for 16 minutes;

[0040] Step S2, granulation: add the above mixed medicinal powder into a dry granulator for dry granulation; the parameters of the granulator are: stirring speed 25rpm, screw speed 80rpm, pressure roller speed 16rpm, pressure roller gap 1.1mm, granulation speed 80rpm , Roller pressure 120bar, sieve size 1.0mm, vacuum 0.1bar;

[0041]Step S3, batch mixing: add the above granules and 0.5% magnesium stearate into a three-dimensional motion mixer, and mix for 10 minutes at a frequency of 10 Hz;

[0042] Step S4, capsule filling: put the above mixed powder into a capsule filling machine to fill capsules.

Embodiment 2

[0044] The microcrystalline cellulose in Step S1 of Example 1 was replaced by dextrin, the sodium carmellose was replaced by methyl cellulose, the magnesium stearate in Step S3 was replaced by stearic acid, and the rest remained unchanged.

Embodiment 3

[0046] The microcrystalline cellulose in step S1 of Example 1 was replaced with sorbitol, the sodium carmellose was replaced with hydroxypropyl cellulose, the magnesium stearate in step S3 was replaced with talcum powder, and the rest remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com