Preparation method of cobalt-nickel sulfide electrode material and batteries

A cobalt-nickel sulfide and electrode material technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, hybrid capacitor electrodes, etc., can solve short cycle life, shedding or pulverization of active materials, low conductivity and other problems, to achieve uniform size, improve conductivity, and accelerate transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

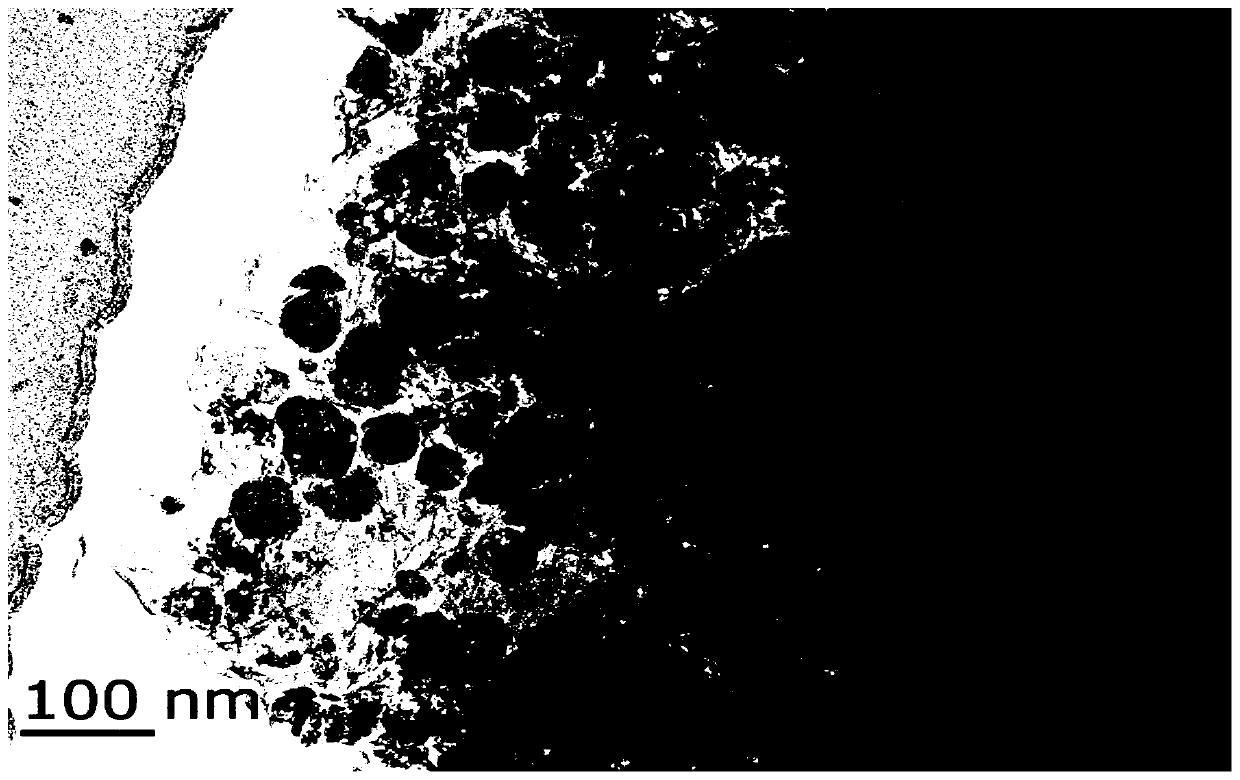

Embodiment 1

[0044] This embodiment is the preparation embodiment of product 1, and concrete steps are as follows:

[0045] 1. Add 87.5 mg of graphene oxide to 175 mL of ethylene glycol solution, and use an ultrasonic breaker to sonicate for 1 hour to obtain a uniformly dispersed graphene oxide dispersion with a concentration of 0.5 mg / mL; mix 0.025 mol of nickel acetate and 0.05 mol of acetic acid Cobalt and 0.075mol polyacrylic acid were dissolved in the graphene oxide dispersion, ultrasonically dispersed for 1 hour, then placed in a water bath, and stirred at 80°C for 2 hours to obtain the first product. Among them, the average molecular weight of polyacrylic acid is 2000.

[0046] 2. Add 0.1 mol thiourea to the first product, and stir at room temperature for 30 minutes to obtain the second product.

[0047]3. Pour the second product into a polytetrafluoroethylene reactor, and react at 200° C. for 12 hours to obtain the third product.

[0048] 4. The third product was washed three tim...

Embodiment 2

[0050] This embodiment is the preparation embodiment of product 2, and concrete steps are as follows:

[0051] 1. Add 350 mg of graphene oxide to 175 mL of ethylene glycol solution, and use an ultrasonic breaker to sonicate for 1 hour to obtain a uniformly dispersed 2 mg / mL graphene oxide dispersion; add 0.025 mol of nickel acetate, 0.05 mol of cobalt acetate and 0.075 mol of Polyacrylic acid was dissolved in the graphene oxide dispersion liquid, ultrasonically dispersed for 1 h, then placed in a water bath, and stirred at 80° C. for 2 h to obtain the first product. Among them, the average molecular weight of polyacrylic acid is 2000.

[0052] 2. Add 0.1 mol thiourea to the first product, and stir at room temperature for 30 minutes to obtain the second product.

[0053] 3. Pour the second product into a polytetrafluoroethylene reactor, and react at 200° C. for 12 hours to obtain the third product.

[0054] 4. The third product was washed three times with deionized water, and...

Embodiment 3

[0056] This embodiment is the preparation embodiment of product 3, and concrete steps are as follows:

[0057] 1. Add 175mg of graphene oxide to 175mL of ethylene glycol solution, and use an ultrasonic crusher to sonicate for 1 hour to obtain a uniformly dispersed 1mg / mL graphene oxide dispersion; add 0.025mol of nickel acetate, 0.05mol of cobalt acetate and 0.075mol of Polyacrylic acid was dissolved in the graphene oxide dispersion liquid, ultrasonically dispersed for 1 h, then placed in a water bath, and stirred at 80° C. for 2 h to obtain the first product. Among them, the average molecular weight of polyacrylic acid is 2000.

[0058] 2. Add 0.1 mol thiourea to the first product, and stir at room temperature for 30 minutes to obtain the second product.

[0059] 3. Pour the second product into a polytetrafluoroethylene reactor, and react at 200° C. for 12 hours to obtain the third product.

[0060] 4. The third product was washed three times with deionized water, and dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com