Method for passivating perovskite and perovskite solar cell

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as unfavorable photo-generated carrier transport, reduced charge transport capacity, and affect film performance. The method is simple and convenient, Improvement of efficiency and stability, effect of low defect state density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1 - Using NMP (N-methylpyrrolidone) as a solvent or mixing agent

[0058] Preparation:

[0059] According to the method provided by the present invention, the PbI 2 , CsI and NMP were dissolved in DMF (N,N-dimethylformamide) at a molar ratio of 1:1:1, heated at 70°C and continuously stirred for 1 hour to completely dissolve to obtain CsPbI 3 Perovskite precursor solution, concentration is 1mol / L; Substrate (conductive glass / dense ZnO-ZnS layer / mesoporous TiO 2 Layer composition) in the air atmosphere, annealed at 550 ° C for 30 minutes and then lowered to room temperature, then transferred the substrate to a glove box; the CsPbI 3 The perovskite precursor solution was spin-coated on the substrate at a speed of 3000 rpm for 30 seconds, and heated at 140°C containing CsPbI 3 Substrate of perovskite precursor solution for 20 minutes to generate black perovskite phase of CsPbI 3 Perovskite thin film; the hole transport layer material spiro-OMeTAD chlorobenzene...

Embodiment 2

[0062] Example 2 - Using DMF (N,N-dimethylacetamide) as a solvent or mixing agent

[0063] Preparation:

[0064] According to the method provided by the present invention, the PbI 2 , CsI and DMF were dissolved in DMF at a molar ratio of 1:1:1, heated at 70°C and stirred continuously for 1 hour to dissolve completely, and CsPbI was obtained 3 Perovskite precursor solution, concentration is 1mol / L; Substrate (conductive glass / dense ZnO-ZnS layer / mesoporous TiO 2 Layer composition) in the air atmosphere, annealed at 550 ° C for 30 minutes and then lowered to room temperature, then transferred the substrate to a glove box; the CsPbI 3 The perovskite precursor solution was spin-coated on the substrate at a speed of 3000 rpm for 30 seconds, and heated at 140°C containing CsPbI 3 Substrate of perovskite precursor solution for 20 minutes to generate black perovskite phase of CsPbI 3 Perovskite thin film; After the chlorobenzene solution (concentration 30mg / mL), TBP and Li-TFSI ...

Embodiment 3

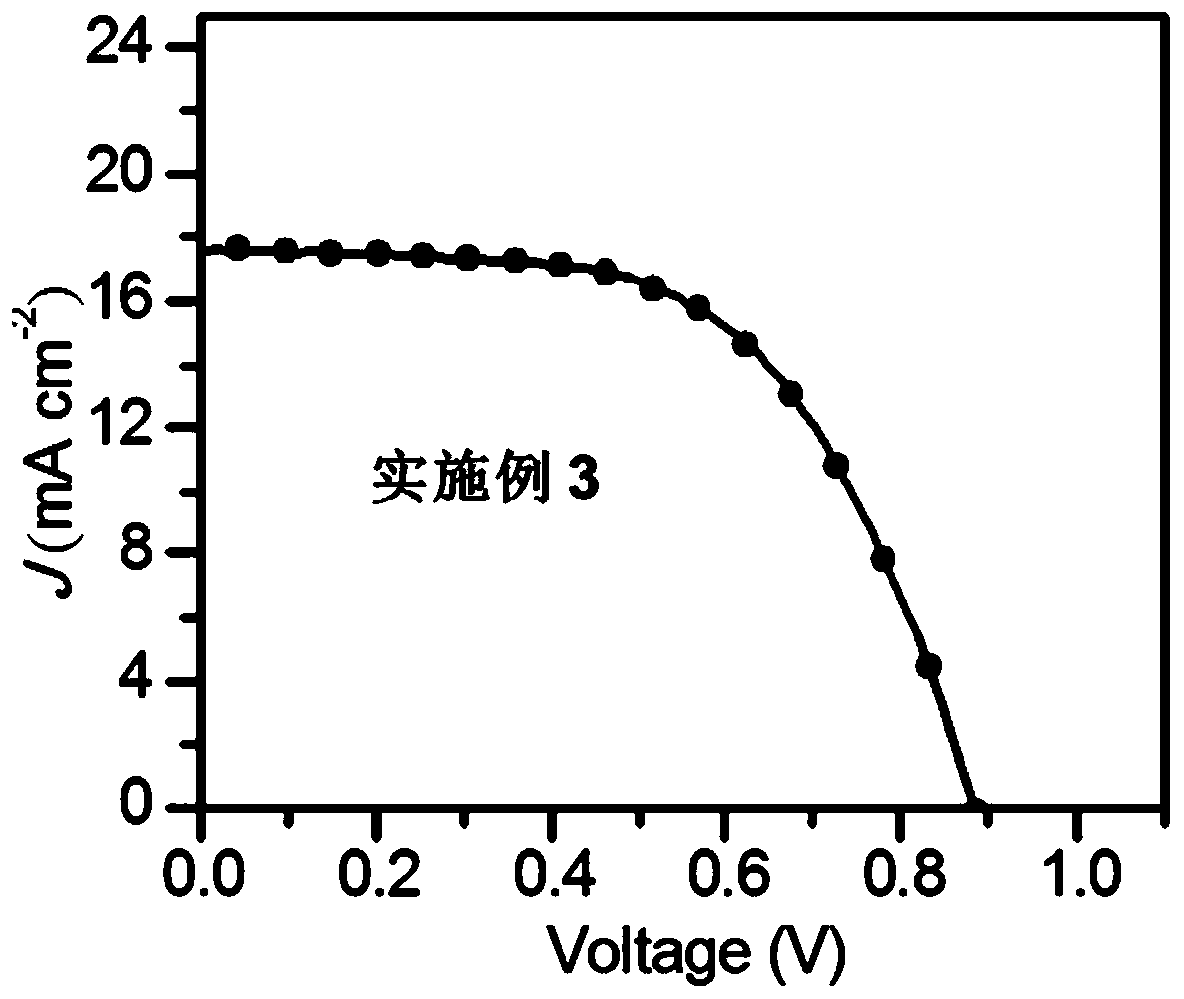

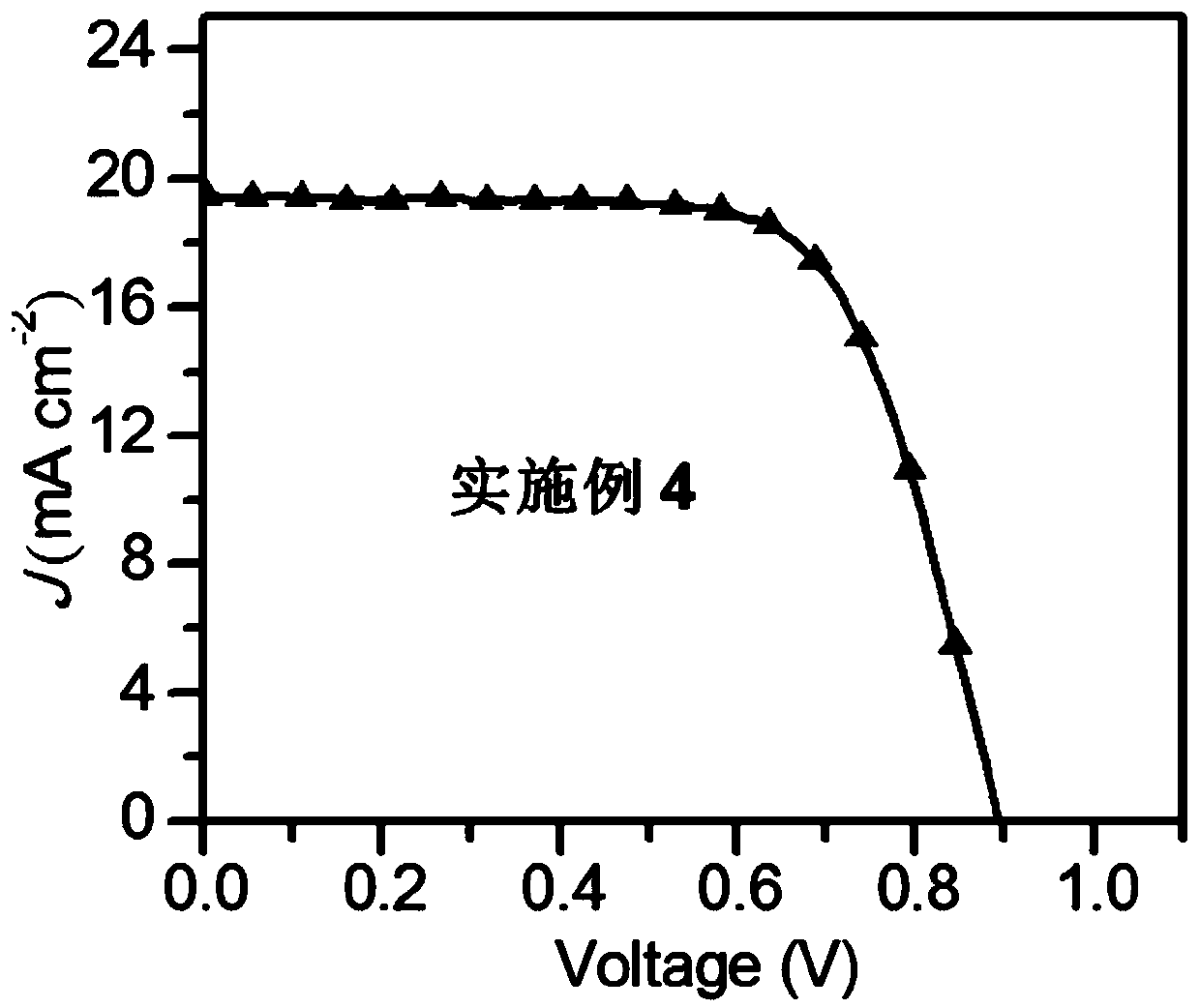

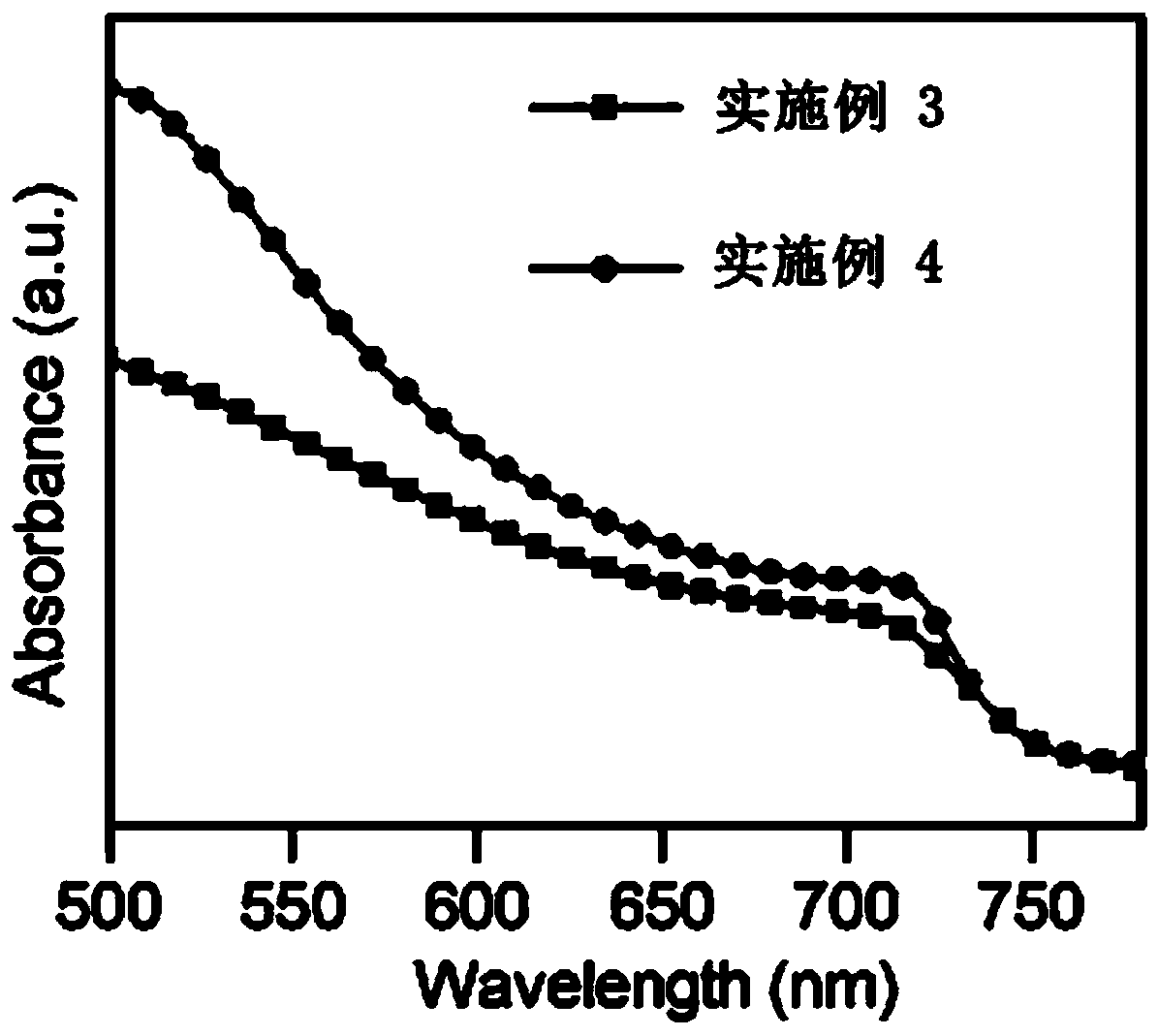

[0067] Example 3 - Passivation of Perovskites Using Cyclic Ether Doping

[0068] Preparation:

[0069] According to the method provided by the present invention, the PbI 2 Dissolve CsI and CsI in NMP at a molar ratio of 1:1, heat at 70°C and stir continuously for 1 hour to completely dissolve to obtain CsPbI 3 Perovskite precursor solution, the concentration is 1mol / L; the powder of 2mg 18-crown-6 is added to the CsPbI 3 In the perovskite precursor solution, ultrasonic mixing is uniform, and the doped CsPbI 3 Perovskite precursor solution; the substrate (conductive glass / dense ZnO-ZnS layer / mesoporous TiO 2 Layer composition) in the air atmosphere, 550 ° C annealed for 30 minutes and then lowered to room temperature, then transferred the substrate to a glove box; the doped CsPbI 3 The perovskite precursor solution was spin-coated on the substrate at a speed of 3000 rpm for 30 seconds, and heated at 140°C containing the doped CsPbI 3 Substrate of perovskite precursor sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com