Barley pentosan beverage and making method thereof

A pentosan and beverage technology, applied in the field of barley pentosan beverage and its production, can solve the problems of complex production steps, poor taste, unbalanced nutrition, etc., and achieve the effect of enriching vitamins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

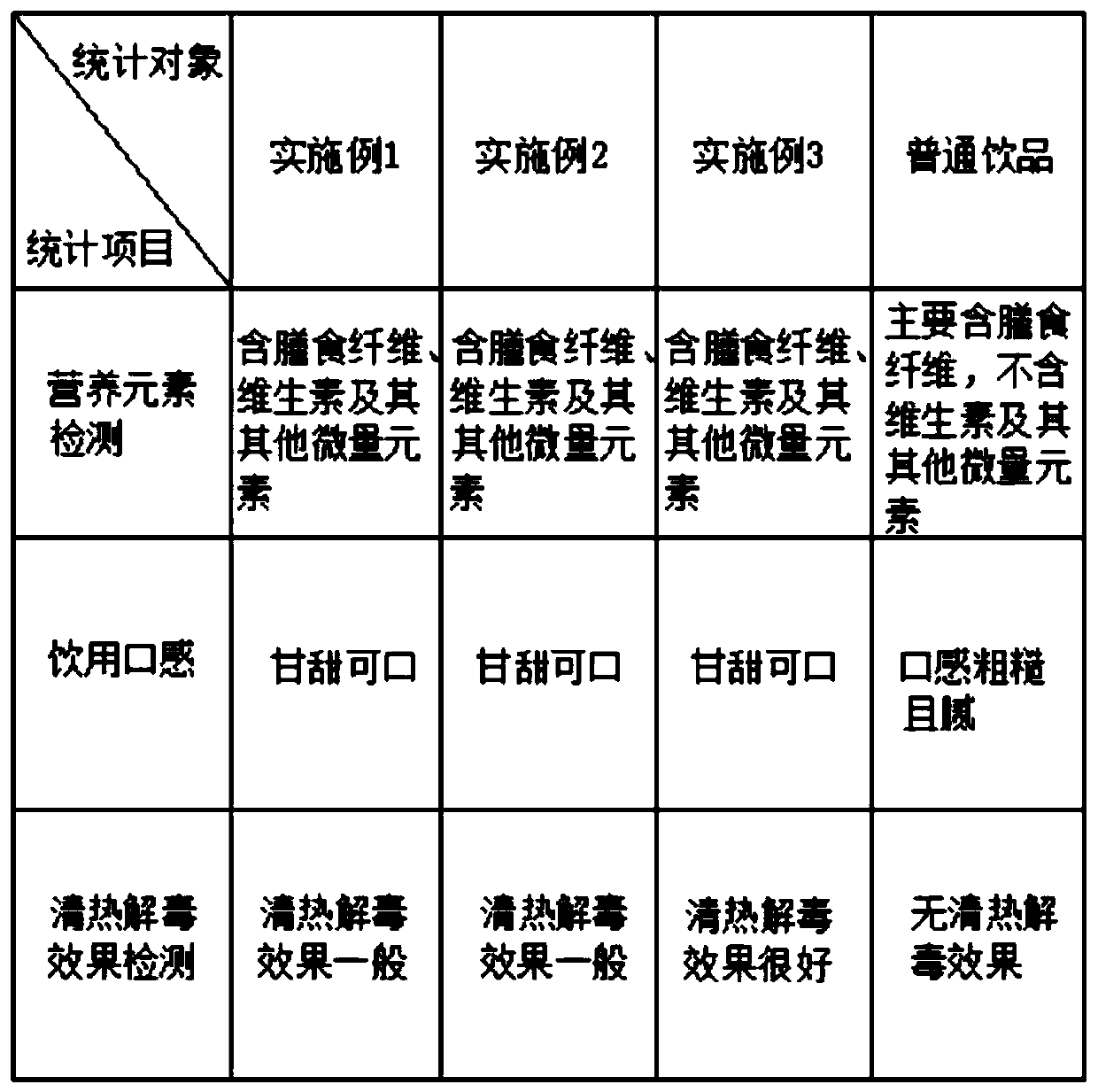

Examples

Embodiment 1

[0027] S1. Select 20 parts of raw wheat bran, 15 parts of carrots, 10 parts of pure milk, 13 parts of pure water, 16 parts of hawthorn, 9 parts of honey, 7 parts of fruit mixture, 6 parts of dendrobium, 5 parts of lotus seed pulp and 3 parts of lactic acid bacteria, Weigh the raw materials by weight;

[0028] S2. Filter the wheat bran selected in S1 to a size of 30 mesh, wash the wheat bran with clean water, and then use protease for enzymatic hydrolysis, and inactivate the protease at 70 °C, and at the same time gelatinizing starch, enzymatic hydrolysis with high temperature resistant α-amylase, drying after filtration, adding alkali hydrolysis to obtain deproteinized and de-starch wheat bran, and filtering starch wheat bran to obtain pentosan;

[0029] S3, add the hawthorn and carrot selected in S1 into the large-scale slag juice machine, fully stir the hawthorn and carrot, stir for 2 minutes, and control the rotation speed at 200r / min. Hawthorn and carrot extract;

[0030...

Embodiment 2

[0034] S1. Select 30 parts of raw wheat bran, 22 parts of carrots, 8 parts of pure milk, 10 parts of pure water, 13 parts of hawthorn, 7 parts of honey, 5 parts of fruit mixture, 4 parts of dendrobium, 3 parts of lotus seed pulp and 2 parts of lactic acid bacteria, Weigh the raw materials by weight;

[0035] S2. Filter the wheat bran selected in S1 to a size of 40 mesh, wash the wheat bran with clean water, and then use protease for enzymatic hydrolysis, and deactivate the protease at 80 °C, and at the same time gelatinizing starch, enzymatic hydrolysis with high temperature resistant α-amylase, drying after filtration, adding alkali hydrolysis to obtain deproteinized and de-starch wheat bran, and filtering starch wheat bran to obtain pentosan;

[0036]S3. Add the hawthorn and carrot selected in S1 into the large slag juice machine, fully stir the hawthorn and carrot, stir for 2.5min, and control the rotation speed at 220r / min. After the stirring, the slag in the mixture is dr...

Embodiment 3

[0041] S1. Select 40 parts of raw wheat bran, 28 parts of carrots, 6 parts of pure milk, 8 parts of pure water, 10 parts of hawthorn, 4 parts of honey, 3 parts of fruit mixture, 2 parts of dendrobium, 2 parts of lotus seed pulp and 1 part of lactic acid bacteria, Weigh the raw materials by weight;

[0042] S2. Filter the wheat bran selected in S1 to a size of 50 mesh, wash the wheat bran with clean water, and then use protease for enzymatic hydrolysis, and inactivate the protease at 85°C, and at the same time gelatinizing starch, enzymatic hydrolysis with high temperature resistant α-amylase, drying after filtration, adding alkali hydrolysis to obtain deproteinized and de-starch wheat bran, and filtering starch wheat bran to obtain pentosan;

[0043] S3. Add the hawthorn and carrot selected in S1 into the large slag juice machine, fully stir the hawthorn and carrot, stir for 3 minutes, and control the rotation speed at 250r / min. Hawthorn and carrot extract;

[0044] S4. Pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com