A bacterial cellulose-based asymmetric bilateral heterosexual biological patch and its preparation method

A technology of bacterial cellulose and bacterial cellulose film, which is applied in the field of bacterial cellulose-based asymmetric bilateral heterosexual biological patch and its preparation, can solve the problem of lack of bilateral heterosexual performance, insufficient anti-adhesion effect, poor adaptability, etc. problems, to achieve the effect of facilitating the expansion of production, easy control of sample shape and size, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of a bacterial cellulose-based asymmetric bilateral heterosexual biological patch, the preparation method comprising the steps of:

[0033] (1) slowly dehydrating the bacterial cellulose saturated with water;

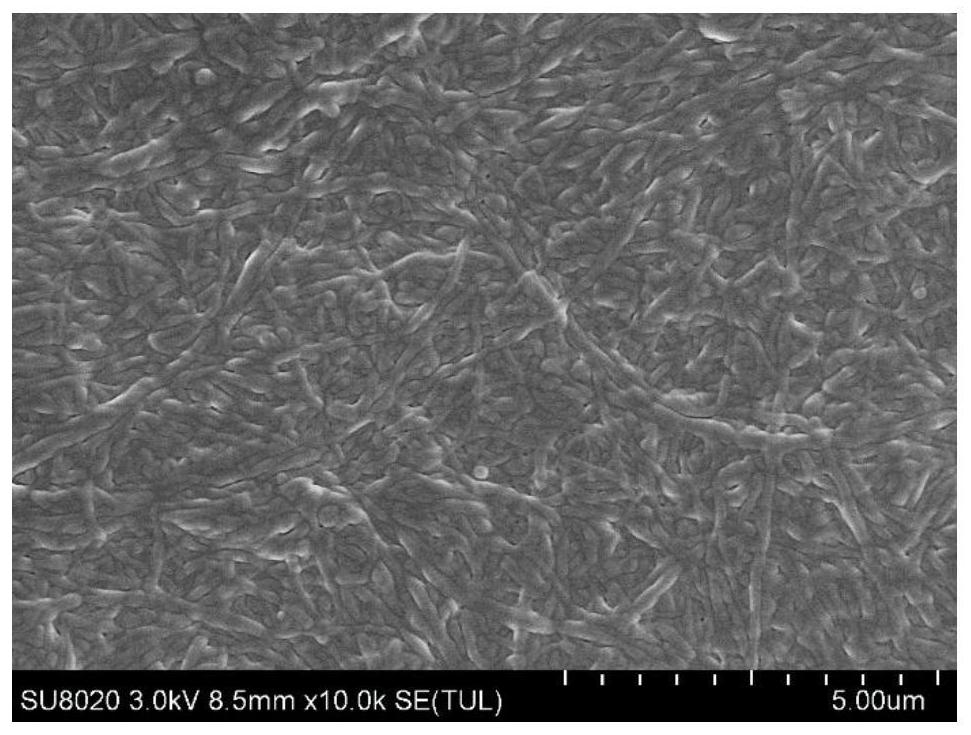

[0034] (2) using femtosecond or millisecond laser drilling technology to prepare micropores of a certain density and size on the surface of the bacterial cellulose semi-dry film obtained in step (1);

[0035](3) The microporous bacterial cellulose semi-dry film obtained through step (2) adopts a vacuum end-capping method to make its side with micropores closely adhere to the mold surface by vacuuming, and then place it in a closed reaction vessel, Using high temperature and high pressure single-sided chemical vapor deposition method, the other side is modified with a long carbon chain hydrophobic modifier for unilateral anti-adhesion modification;

[0036] (4) After the reaction vessel was cooled to room temperature, the material was taken o...

Embodiment 1

[0052] The commercially available BC prepared from Acetobacter xylinum was cut into a BC sample of 4cm×4cm.

[0053] Step 1, pretreating BC with lye to obtain a bacterial cellulose film with a pH value of about 7.3;

[0054] Step 2. Place the pretreated BC membrane flat on a smooth flat plate, then place a flat plate on the BC membrane, apply a weight of 10KG on the flat plate, and press out part of the moisture in the BC membrane for 30 minutes. , and then apply a weight of 20KG on the plate for 30 minutes, and so on, until no more water flows out of the BC film, and finally place the BC film in a drying mold and dry it in vacuum at 30°C for 12 hours to obtain BC semi-dry Membrane, put it in a ziplock bag and save it for later use;

[0055] Step 3. Evenly spread the BC semi-dry film treated in step 2 on the mold, and use a carbon dioxide laser drilling machine to prepare a density of 1000 pieces / cm on one side of the surface. 2 , micropores with a diameter of 200 μm;

[00...

Embodiment 2

[0060] The commercially available BC prepared from Acetobacter xylinum was cut into a BC sample of 4cm×4cm.

[0061] Step 1, pretreating BC with lye to obtain a bacterial cellulose film with a pH value of about 7.3;

[0062] Step 2. Place the pretreated BC membrane flat on a smooth flat plate, then place a flat plate on the BC membrane, apply a weight of 10KG on the flat plate, and press out part of the moisture in the BC membrane for 30 minutes. , and then apply a weight of 20KG on the plate for 30 minutes, and so on, until no more water flows out of the BC film, and finally place the BC film in a drying mold and dry it in vacuum at 30°C for 12 hours to obtain BC semi-dry Membrane, put it in a ziplock bag and save it for later use;

[0063] Step 3. Evenly spread the BC semi-dry film treated in step 2 on the mold, and use a carbon dioxide laser drilling machine to prepare a density of 1000 pieces / cm on one side of the surface. 2 , micropores with a diameter of 100 μm;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com