Catalyst for catalyzing acetylene to directly prepare styrene, and preparation method and application thereof

A catalyst and styrene technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of polyvinyl chloride overcapacity and low industrial profits, and achieve industrial application, short process routes, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

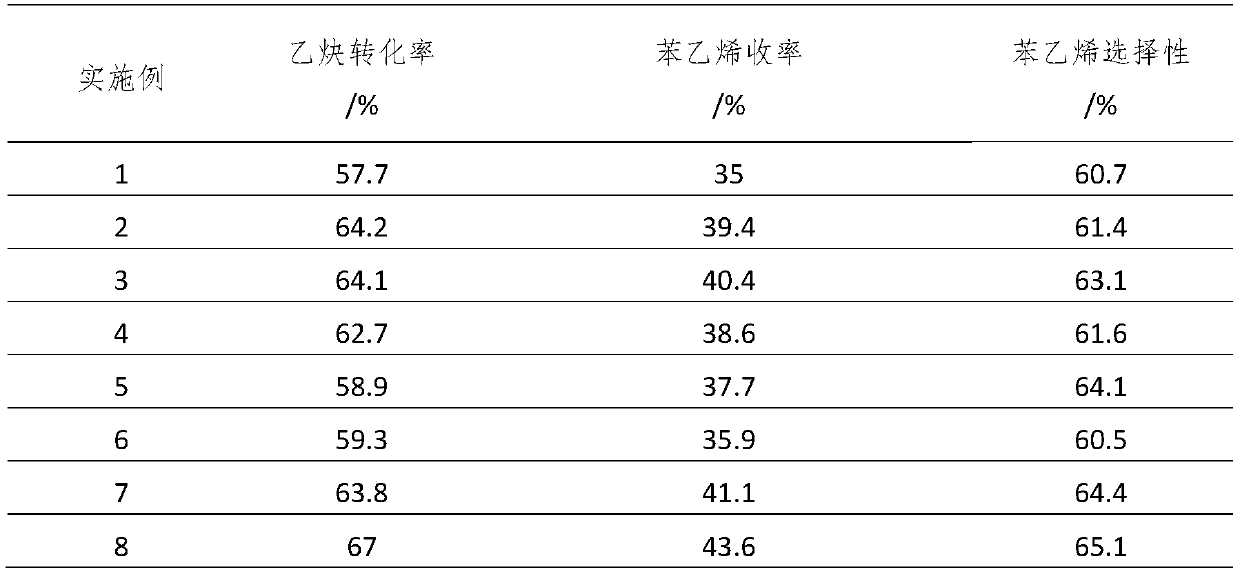

Examples

Embodiment 1

[0041] (1) Catalyst preparation

[0042]Catalyst component palladium: niobium: H-ZSM-5 molecular sieve mass ratio = 0.5:5:94.5. Select H-ZSM-5 molecular sieve with a silicon-aluminum ratio of 260 for thermal activation roasting treatment, roasting temperature is 550°C, and roast for 8 hours; then weigh 2.89g of niobium oxalate and 9.45g of activated molecular sieve; add niobium oxalate to 10mL Heat and stir in deionized water to form a uniform metal oxide precursor solution; drop the metal oxide precursor solution into molecular sieves for impregnation, and perform ultrasonic treatment for 2 hours after the addition; dry after ultrasonic treatment at a drying temperature of 80°C. The time is 10 hours; after drying, the catalyst precursor is obtained by roasting at a roasting temperature of 350° C. and a roasting time of 5 hours. Weigh 0.11 g of palladium nitrate and add it to 10 mL of dilute nitric acid solution with a concentration of 0.1 mol / L, heat and stir to form a unifo...

Embodiment 2

[0046] (1) Catalyst preparation

[0047] Catalyst component palladium: niobium: H-ZSM-5 molecular sieve mass ratio = 1:8:91. Select H-ZSM-5 molecular sieve with a silicon-aluminum ratio of 260 for thermal activation roasting treatment, roasting temperature 600°C, and roast for 6 hours; then weigh 4.62g of niobium oxalate and 9.1g of activated molecular sieve; add niobium oxalate to 10mL Heat and stir in deionized water to form a uniform metal oxide precursor solution; add the metal oxide precursor solution dropwise into molecular sieves for impregnation, and perform ultrasonic treatment for 3 hours after the dropwise addition; dry after ultrasonic treatment at a drying temperature of 100°C. The time is 8 hours; after drying, the catalyst precursor is obtained by calcining at a calcining temperature of 400°C and for a calcining time of 4 hours. Weigh 0.22 g of palladium nitrate and add it to 10 mL of dilute nitric acid solution with a concentration of 0.1 mol / L, heat and stir ...

Embodiment 3

[0051] (1) Catalyst preparation

[0052] Catalyst component palladium: niobium: H-ZSM-5 molecular sieve mass ratio = 0.8:7:92.2. Select H-ZSM-5 molecular sieve with a silicon-aluminum ratio of 260 for heat-activated roasting treatment at a roasting temperature of 550°C for 8 hours; then weigh 4.05g of niobium oxalate and 9.22g of activated molecular sieve; add niobium oxalate to 10mL Heat and stir in deionized water to form a uniform metal oxide precursor solution; add the metal oxide precursor solution dropwise into molecular sieves for impregnation, and perform ultrasonic treatment for 3 hours after the dropwise addition; dry after ultrasonic treatment at a drying temperature of 100°C. The time is 8 hours; after drying, the catalyst precursor is obtained by calcining at a calcining temperature of 400°C and for a calcining time of 4 hours. Weigh 0.18 g of palladium nitrate and add it to 10 mL of dilute nitric acid solution with a concentration of 0.1 mol / L, heat and stir to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com