Method for preparing high-conductivity porous copper foil based on brass strip

A brass strip and high-conductivity technology, which is applied in the field of preparing high-conductivity porous copper foil based on brass strip, can solve problems such as the inability to improve the conductivity of brass, and achieve the effects of improving surface gloss, reducing costs, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

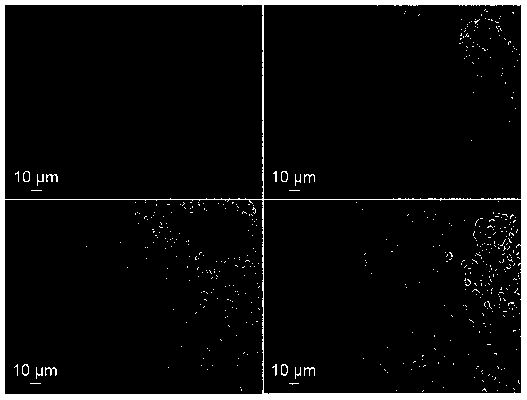

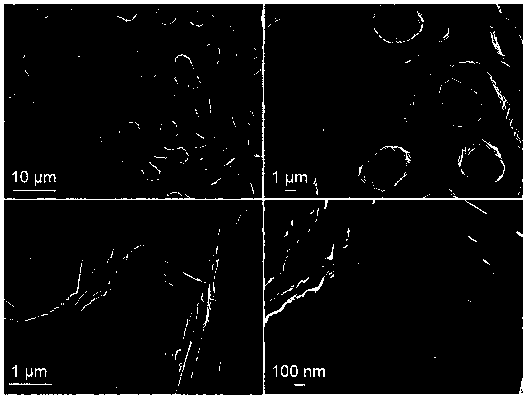

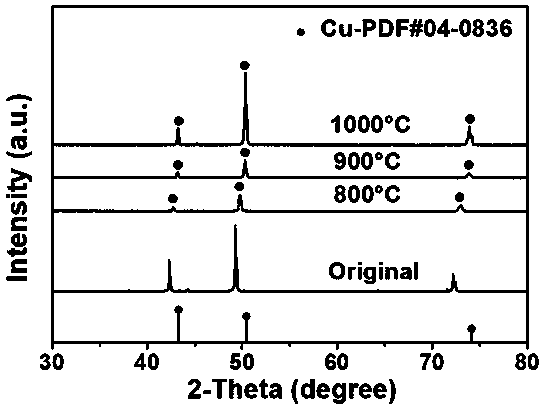

[0030] Select the brass strip of model H64, use ethanol or acetone, hydrochloric acid or sulfuric acid with a concentration of 0.1-2 mol / L as the cleaning agent, and clean the brass surface in sequence, such as degreasing and derusting, and then clean the brass surface and clean it. Dry and set aside. The above samples were chemically modified using sodium borohydride aqueous solution with a concentration of 1 mol / L as a reducing agent, and the chemical treatment time was 15 minutes. After chemical modification, the sample surface was blown dry with nitrogen flow. The sample was annealed under a certain temperature program. First, the heating rate was 10 °C / min, the heat treatment temperature was 600 °C, and the heat treatment time was 30 min. Then the heating rate was 5 °C / min, and the heat treatment temperature was 800 °C. The time is 30 minutes. During the whole annealing heat treatment, the protective gas used is nitrogen. The cooling method after annealing heat treatme...

Embodiment 2

[0033] Select the brass strip of model H64, use ethanol or acetone, hydrochloric acid or sulfuric acid with a concentration of 0.1-2 mol / L as the cleaning agent, and clean the brass surface in sequence, such as degreasing and derusting, and then clean the brass surface and clean it. Dry and set aside. The above samples were chemically modified by using sodium borohydride aqueous solution with a concentration of 0.5 mol / L as a reducing agent, and the chemical treatment time was 30 minutes. After chemical modification, the sample surface was blown dry with nitrogen flow. The sample was annealed under a certain temperature program. First, the heating rate was 15 °C / min, the heat treatment temperature was 500 °C, and the heat treatment time was 60 min. Then, the heating rate was 10 °C / min, and the heat treatment temperature was 700 °C. The time is 60 minutes. During the entire annealing heat treatment, the protective gas used is high-purity argon. The cooling method after annea...

Embodiment 3

[0035]Select the brass strip of model H64, use ethanol or acetone, hydrochloric acid or sulfuric acid with a concentration of 0.1-2 mol / L as the cleaning agent, and clean the brass surface in sequence, such as degreasing and derusting, and then clean the brass surface and clean it. Dry and set aside. The above samples were chemically modified by using sodium borohydride aqueous solution with a concentration of 1 mol / L as a reducing agent. The chemical treatment time is 15min. After chemical modification, the sample surface was blown dry with nitrogen flow. The sample was electrochemically treated at a certain potential and current, the electrolyte used was phosphoric acid with a concentration of 2 mol / L, the potential range was 1-30 V, the current range was 0.1-10 mA, and the treatment time was 15 min. The surface of the sample is mechanically treated to mechanically polish the surface of the sample to obtain the final treated copper foil. After testing, compared with the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com