Flexible self-supporting MXene/zinc composite electrode and preparation method and application thereof

A composite electrode, self-supporting technology, applied in active material electrodes, hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., to achieve good versatility, good hydrophilicity, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

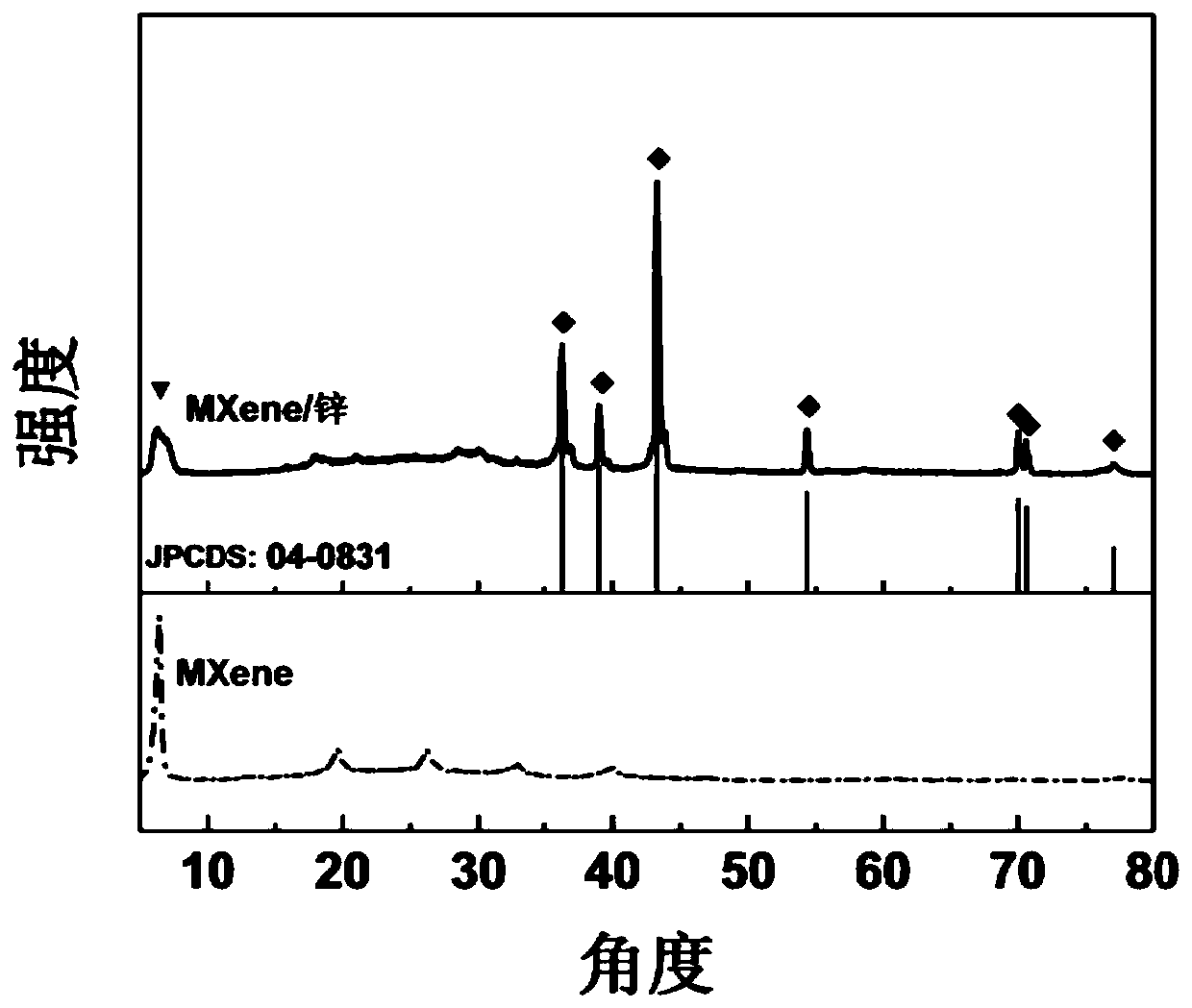

[0044] MAX phase selection most common Ti 3 AlC 2 powder, stirred in a mixed solution of 10ml hydrochloric acid and 0.8g zinc fluoride, then added water and centrifuged to remove excess acid and fluoride, and then peeled off the multilayer MXene by ultrasonic peeling and centrifugation to separate the resulting few-layer / multilayer MXene Colloidal solution, select 50ml of the above-mentioned colloidal solution, after filtering, dry in a vacuum oven at 50 degrees Celsius to obtain a flexible self-supporting three-dimensional layered MXene film;

[0045] Prepare 2 moles per liter of zinc sulfate aqueous solution, use ultrapure water as a solvent, stir at room temperature for half an hour until it is clear and transparent, and obtain an electrodeposition solution containing divalent zinc salt;

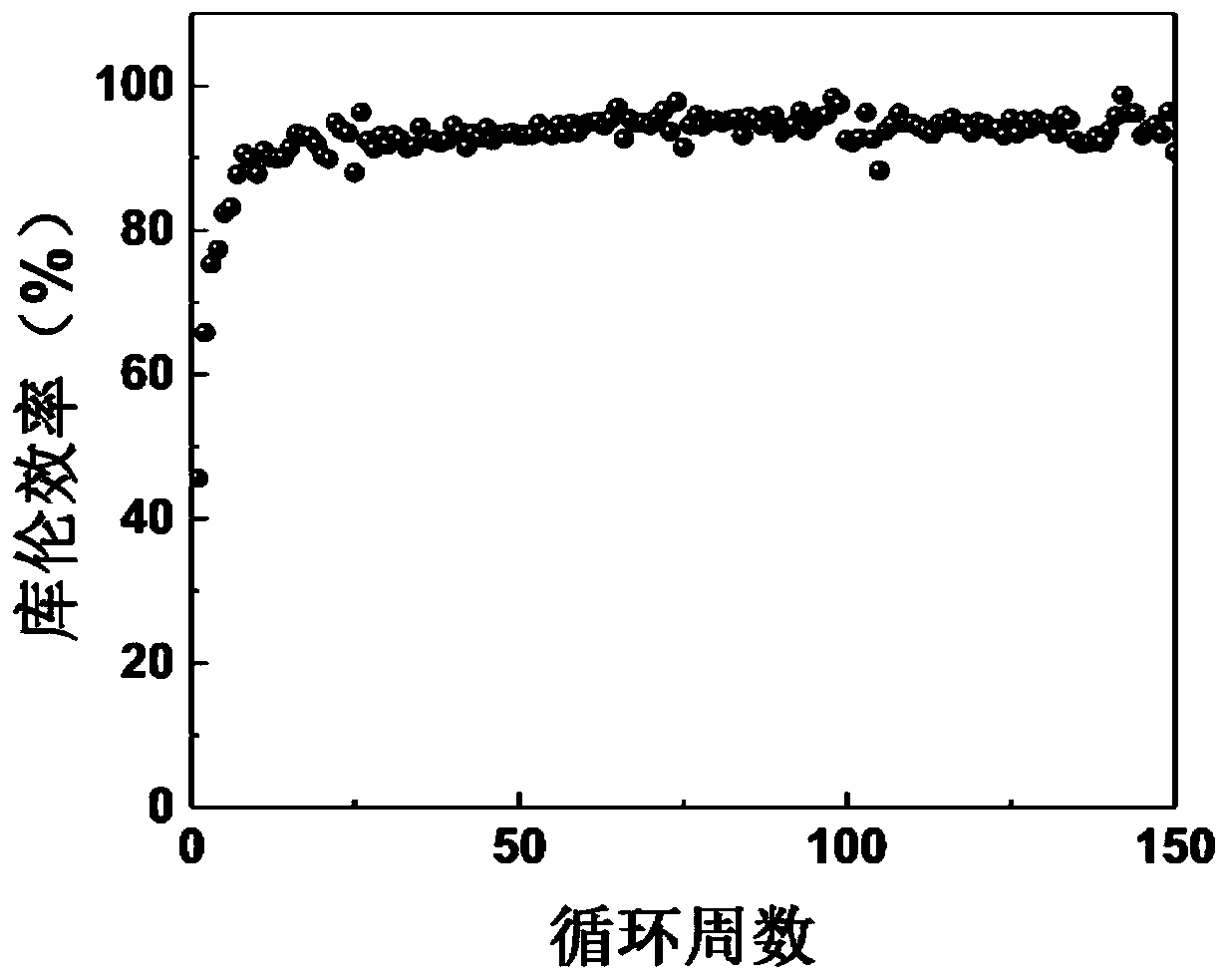

[0046] Subsequently, in the electrolytic tank, put 20ml of electroplating solution, and then deposit a suitable time with a current density of 1 milliampere per square centimeter. The MX...

Embodiment 2

[0051] MAX phase chooses V 2 AlC powder, MAX phase choose V 2 AlC powder, etched with hydrochloric acid and lithium fluoride at 50 degrees Celsius to remove the aluminum atomic layer, then peeled off to obtain MXene colloidal solution, and suction filtered to obtain MXene film; then, prepare 2 moles per liter of zinc chloride aqueous solution for electrodeposition solution, performing electrodeposition in an electrolytic bath.

Embodiment 3

[0053] MAX phase chooses Ti 3 AlC 2 Powder, Example 1 of the preparation method of MXene, the main salt of the electrodeposition solution is zinc chloride, the solvent is dehydrated alcohol, the concentration is 2 moles per liter, electrodeposition and drying are performed under the same electrodeposition conditions as in Example 1 , the three-dimensional layered MXene / Zn composite film can effectively inhibit the growth of metal dendrites when used as a current collector for zinc metal anode and lithium metal anode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com