Near-infrared-shielding ultrafine particle dispersion body, near-infrared-shielding intermediate film, near-infrared-shielding laminated structure, and production method for near-infrared-shielding ultrafine particle dispersion body

A near-infrared, manufacturing method technology, applied in the direction of layered products, chemical instruments and methods, coatings, etc., can solve problems such as reduced productivity of near-infrared shielding particle dispersions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0350]

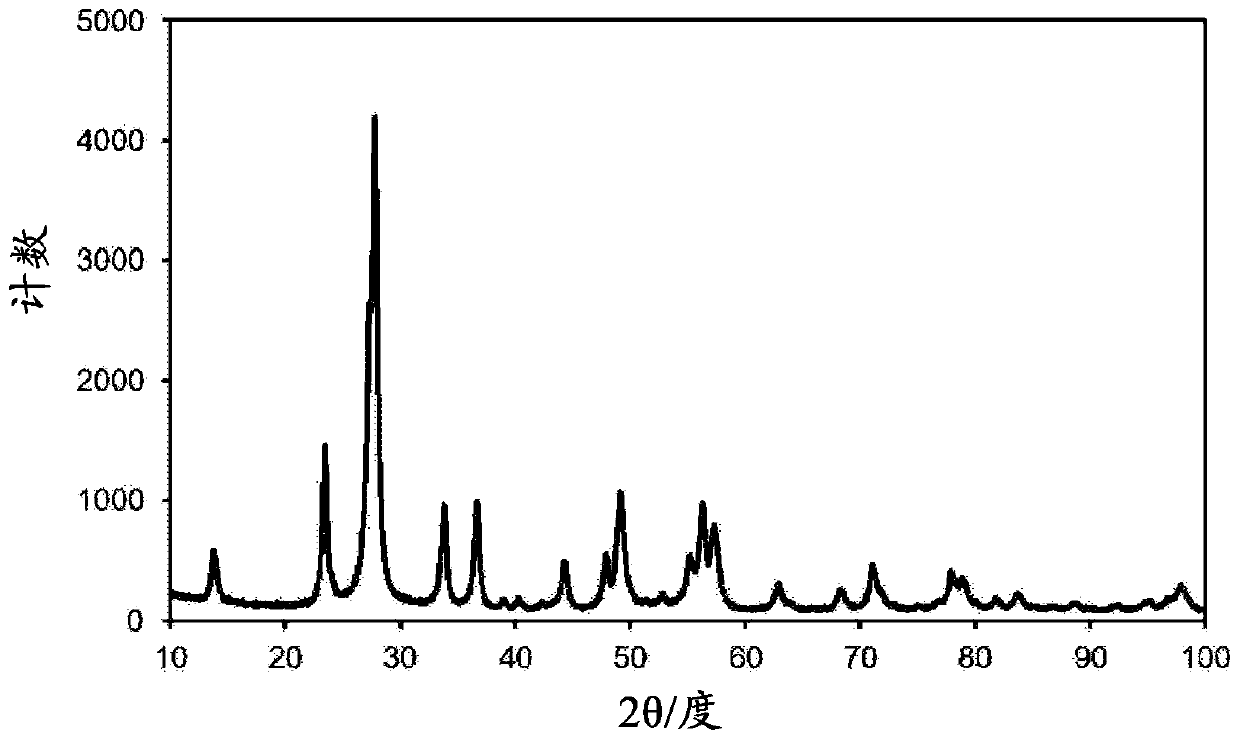

[0351] 0.216kg of Cs 2 CO 3 Dissolve in 0.330kg of water, add it to 1.000kg of H 2 WO 4 and fully stirred, and then dried to obtain the ratio of Cs element to W element as the target composition of Cs 0.33 WO 3 The mixed powder of the ratio of Cs element to W element in the

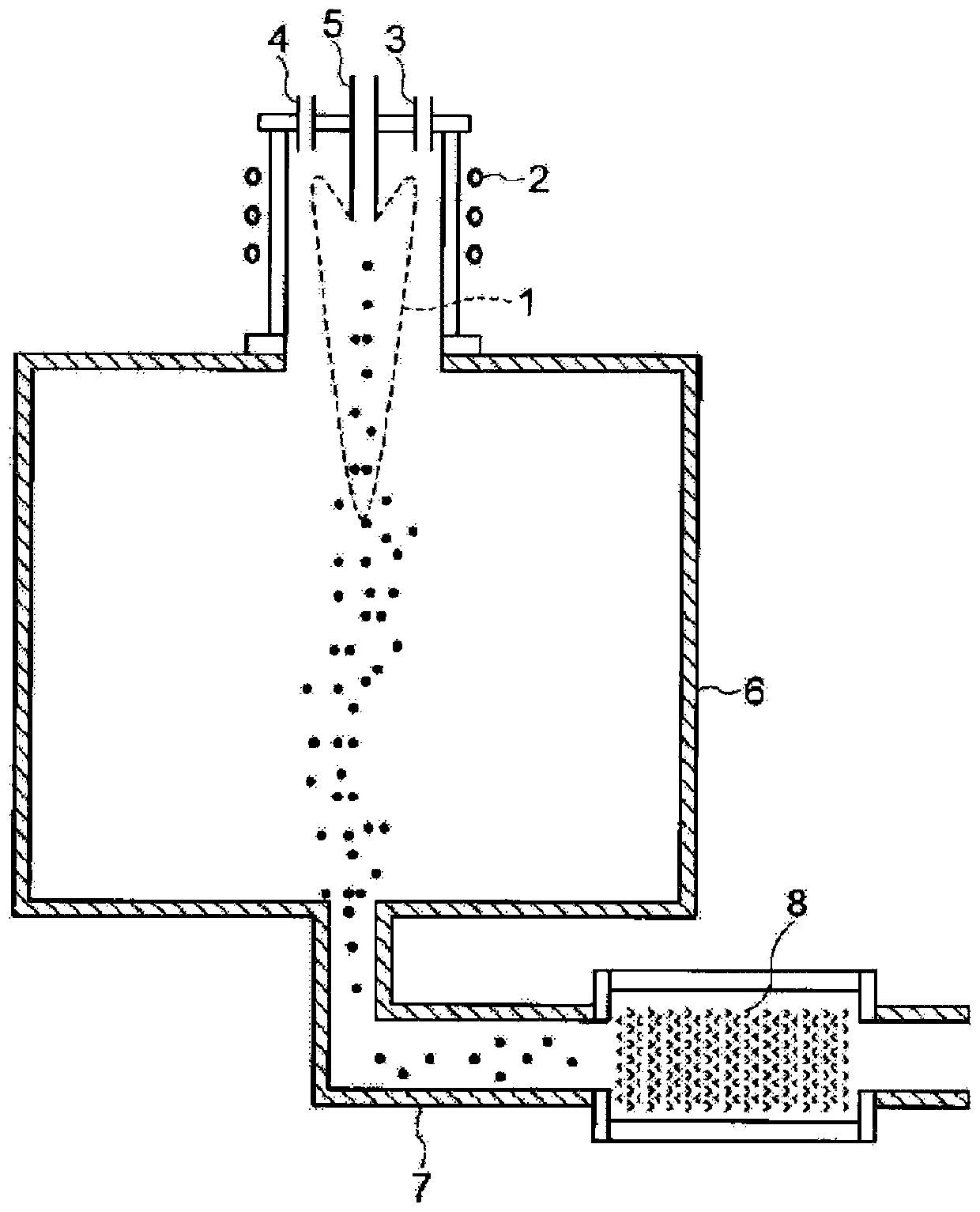

[0352] Next, use figure 1 The high-frequency plasma reaction device shown (manufactured by SUMITOMO METAL MINING Co., Ltd., high-frequency plasma generation department; manufactured by NIKOHA Co., Ltd.; the inner diameter of the water-cooled two-quartz heavy tube is 70 mm, and the length is 213 mm), is pumped by a vacuum exhaust device. The inside of the reaction system was evacuated to about 0.1 Pa, and then completely replaced with argon to make a circulation system of 1 pressure. After that, argon gas was introduced into the reaction vessel from the plasma supply nozzle at a flow rate of 30 L / min as plasma gas, and argon gas at a flow rate of 55 L / min and helium gas at a flow rate of 5...

Embodiment 2~6

[0386] Except changing the carrier gas flow rate, the plasma gas flow rate, the sheath gas flow rate, and the raw material supply rate respectively as prescribed values, carry out the same operation as in Example 1, thereby manufacturing the composite tungsten oxide ultrafine particles of Examples 2 to 6 (A ), using the obtained composite tungsten oxide ultrafine particles (A) to produce a composite tungsten oxide ultrafine particle dispersion. Table 1 shows the changed carrier gas flow rate conditions, raw material supply rate conditions, and other conditions.

[0387] The same evaluation as in Example 1 was performed on the composite tungsten oxide ultrafine particles (A) and composite tungsten oxide ultrafine particle dispersion liquid obtained in Examples 2 to 6. The evaluation results are shown in Table 2 and Table 3.

[0388] In addition, in addition to using the composite tungsten oxide ultrafine particle dispersion liquid of Examples 2 to 6, the same conditions as tho...

Embodiment 7

[0390] The Cs described in embodiment 1 2 CO 3 and H 2 WO 4 The mixed powder is changed to Cs obtained by firing at 800°C in a mixed gas atmosphere of nitrogen and hydrogen. 0.33 WO 3 The composite tungsten oxide indicated by is used as the raw material to be put into the high-frequency plasma reactor.

[0391] The manufacturing conditions of the other composite tungsten oxide ultrafine particles (A) were the same as in Example 1, and the composite tungsten oxide ultrafine particles (A) of Example 7 were obtained.

[0392] The near-infrared shielding ultrafine particle dispersion liquid of Example 7 was produced under the same conditions as in Example 1 using the obtained composite tungsten oxide ultrafine particles (A). The same evaluation as in Example 1 was performed on the obtained composite tungsten oxide ultrafine particles (A) and its dispersion liquid. The production conditions and evaluation results are shown in Tables 1 to 3.

[0393] In addition, except for u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com