A method for recycling waste titanium or titanium alloy powder from additive manufacturing

A technology of additive manufacturing and recycling, which is applied in additive processing, metal processing equipment, transportation and packaging, etc., can solve the problem of the lack of mature recycling and reuse treatment methods for additive manufacturing waste powder, and the quality of titanium or titanium alloy powder Loss, unable to achieve powder impurity content and other issues, to achieve the effect of reducing raw material consumption, improving surface finish, and improving powder utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for recycling waste Ti-6Al-4V titanium alloy powder with an oxygen content of 1900 ppm after 17 cycles of EBM additive manufacturing process. operate:

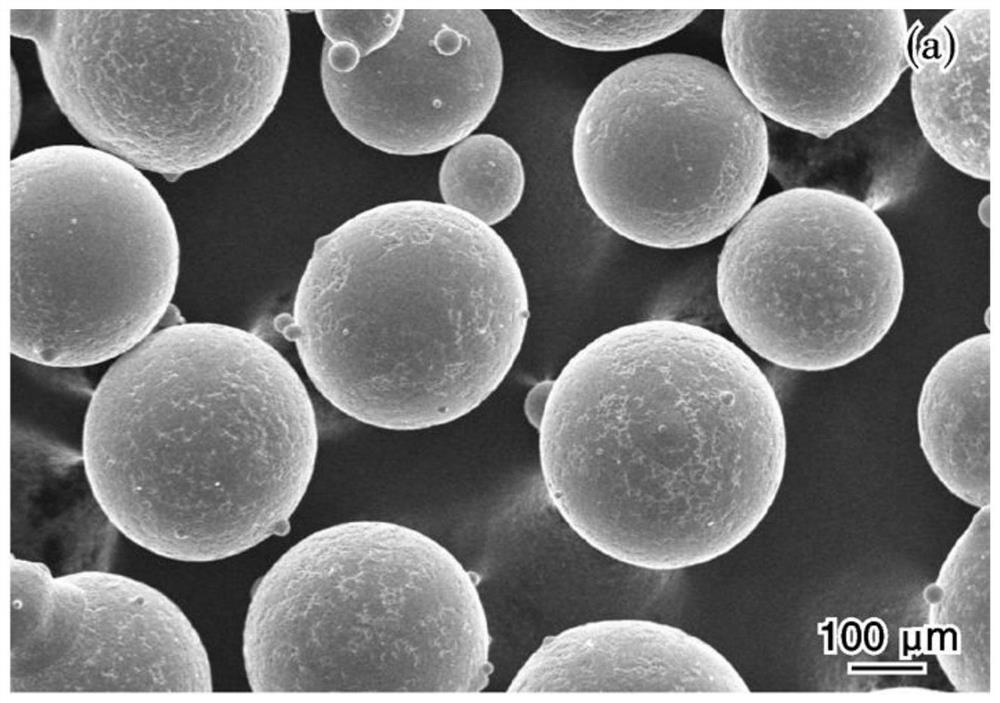

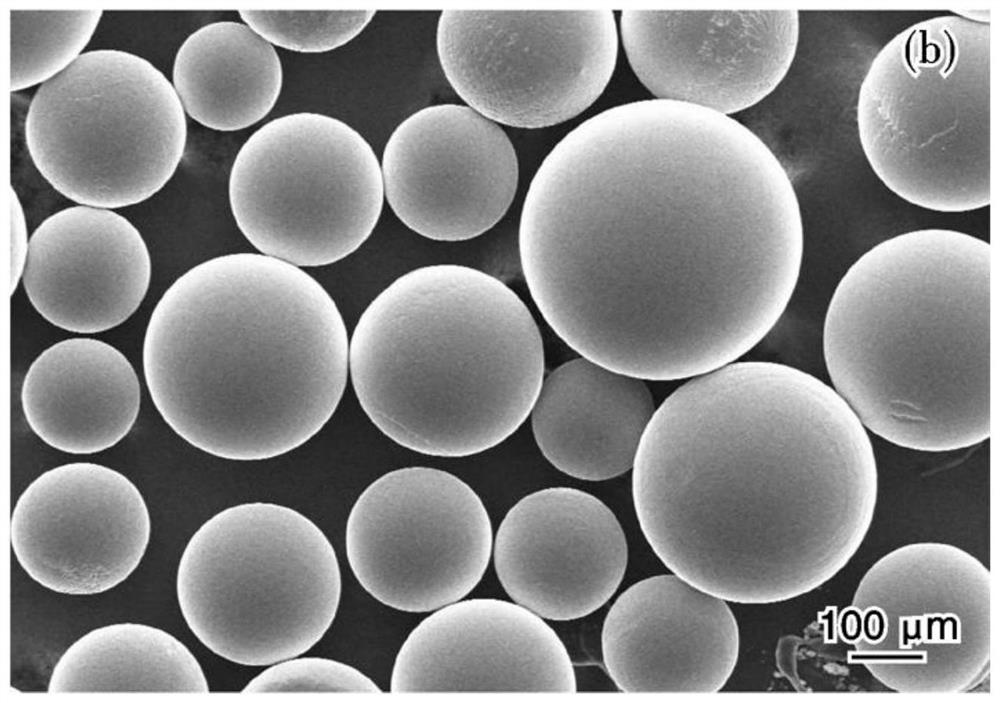

[0041] Step (1), take 1 L of waste titanium alloy powder after 17 cycles of Ti-6Al-4V titanium alloy additive manufacturing, the oxygen content is 1900 ppm, the powder particle size range is 100 μm to 150 μm, and the sodium content is added to the powder 0.5 % sodium amalgam 0.5L to prepare a mixed slurry with a viscosity of 14Pa·s;

[0042] In step (2), the additive manufacturing waste Ti-6Al-4V titanium alloy powder after adding the sodium amalgam to the three-dimensional mixer is used for the mixing operation to make the mixed slurry reach a fluidized state. During the mixing operation, the filling factor is 0.5 , the mixing speed is 110r / min, the mixing temperature is 15℃, and the mixing time is 40min;

[0043] In step (3), under the protective atmosphere of argon, inert gas is introduced into the fluidiz...

Embodiment 2

[0048] The method for recycling the waste pure titanium powder with an oxygen content of 2100 ppm after the pure titanium SLM process is recycled for 29 times, the method steps are as follows: under the protection of an inert gas, the waste titanium or titanium alloy powder is carried out as follows:

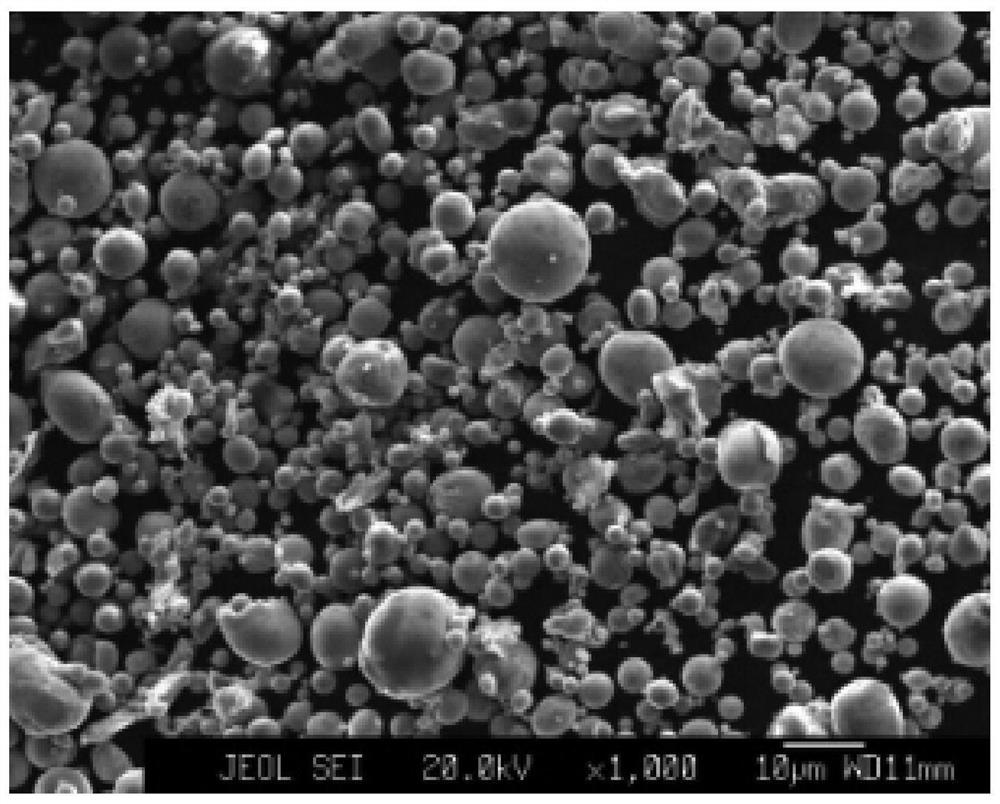

[0049] Step (1), take 0.8L of waste pure titanium powder after 29 cycles of pure titanium additive manufacturing, its oxygen content is 2100ppm, and the powder particle size range is 30 μm to 100 μm, and sodium mercury with a sodium content of 0.4% is added to the powder. 0.5L was filled to prepare a mixed slurry, the viscosity of the mixture was 13Pa·s;

[0050] In step (2), the additive manufacturing waste pure titanium powder after adding the sodium amalgam to the V-shaped mixer is used to carry out the mixing operation to make the mixed slurry reach a fluidized state. During the mixing operation, the filling coefficient is 0.6, and the mixing speed is is 95r / min, the mixing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com