Polyaniline-bimetallic hydroxide supercapacitor material and preparation method thereof

A technology of supercapacitors and hydroxides, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors. It can solve problems such as poor conductivity, reduced cycle stability and service life of electrode materials, and poor chemical stability. Effects of material stabilization, promotion of migration and transport efficiency, and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

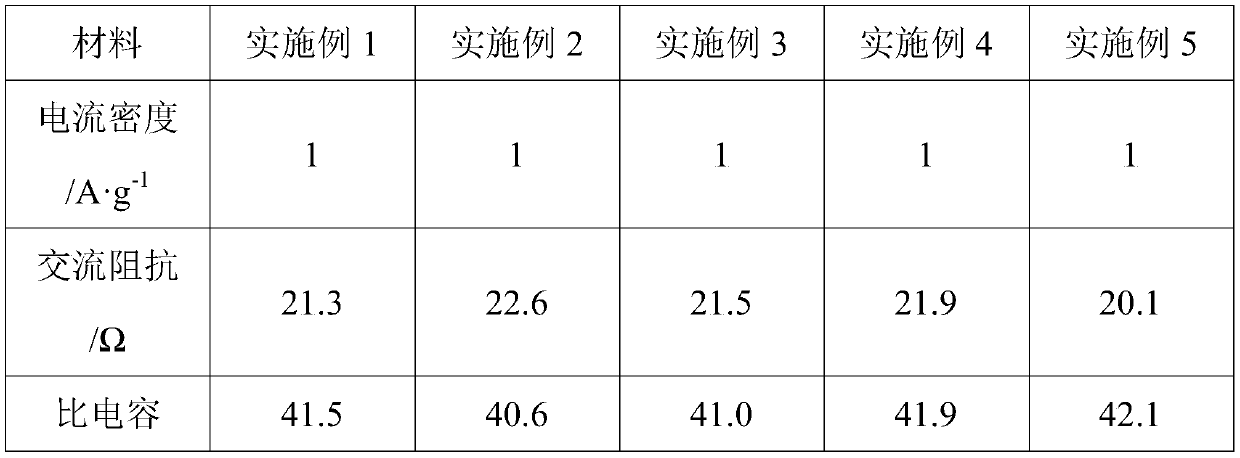

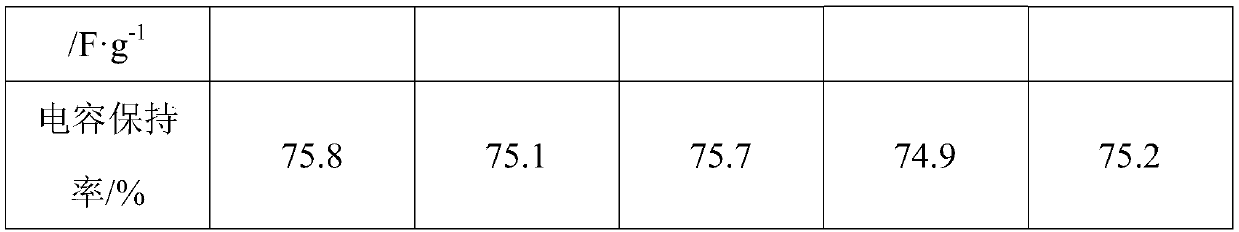

Examples

preparation example Construction

[0020] The preparation method of lanthanum-doped Co-Ag double metal hydroxide comprises the following steps:

[0021] (1) Add an appropriate amount of distilled water to the reaction flask successively, then add anhydrous cobalt chloride and silver nitrate and stir to dissolve, then add dehydrated alcohol and hexamethylenetetramine, the volume ratio of distilled water and dehydrated alcohol is 1.5- 2.5:1, slowly add sodium hydroxide, adjust the pH to 9-10, control the mass fraction of the total solute in the solution to be 3-12%, transfer the solution into the automatic hydrothermal reaction kettle after stirring, and raise the temperature to 120-135°C, stirring at a constant speed for 15-20h, after the reaction, cool the solution to room temperature and filter to remove the solvent, and wash the solid product with distilled water to obtain Co-Ag double metal hydroxide.

[0022] (2) Add an appropriate amount of distilled water to the automatic hydrothermal reaction kettle, the...

Embodiment 1

[0026] (1) Preparation of Co-Ag double metal hydroxide: Add appropriate amount of distilled water to the reaction flask in turn, then add anhydrous cobalt chloride and silver nitrate and stir to dissolve, then add absolute ethanol and hexamethylenetetramine, distilled water The volume ratio with absolute ethanol is 1.5-2.5:1, slowly add sodium hydroxide, adjust the pH to 9-10, control the mass fraction of the total solute in the solution to be 3-12%, and transfer the solution into the automatic In the hydrothermal reaction kettle, raise the temperature to 120-135°C, stir the reaction at a constant speed for 15-20h, after the reaction is completed, cool the solution to room temperature and filter to remove the solvent, and wash the solid product with distilled water to obtain Co-Ag double metal hydroxide 1 .

[0027](2) Preparation of lanthanum-doped Co-Ag double metal hydroxide: Add appropriate amount of distilled water to the automatic hydrothermal reaction kettle, then add l...

Embodiment 2

[0030] (1) Preparation of Co-Ag double metal hydroxide: Add appropriate amount of distilled water to the reaction flask in turn, then add anhydrous cobalt chloride and silver nitrate and stir to dissolve, then add absolute ethanol and hexamethylenetetramine, distilled water The volume ratio with absolute ethanol is 1.5-2.5:1, slowly add sodium hydroxide, adjust the pH to 9-10, control the mass fraction of the total solute in the solution to be 3-12%, and transfer the solution into the automatic In the hydrothermal reaction kettle, raise the temperature to 120-135°C, stir the reaction at a constant speed for 15-20h, after the reaction is completed, cool the solution to room temperature and filter to remove the solvent, and wash the solid product with distilled water to obtain Co-Ag double metal hydroxide 2 .

[0031] (2) Preparation of lanthanum-doped Co-Ag double metal hydroxide: add appropriate amount of distilled water to the automatic hydrothermal reaction kettle, then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com