Production method of probiotic fermented fructus crataegi sweetend roll

A fruit peel and probiotic technology, applied in the field of probiotic fermented hawthorn peel, to achieve the effects of promoting human health, promoting growth and proliferation, and reducing reducing sugar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, lactic acid bacteria ferment hawthorn fruit paeonol

[0047] 1. Preparation of lactic acid bacteria fermented hawthorn peel

[0048] 1. Raw material pretreatment: choose 100g fresh hawthorn as raw material, wash and drain.

[0049] 2. Blending: Put 70g of sucrose into 55g of water, fully dissolve and add the processed hawthorn fruit in step 1.

[0050] 3. Fruit steaming and pulping: After pouring the blended materials obtained in step 2 into a container, put the container in a pressure cooker (with a pressure of 70kpa, add 300g of water to the pot) and cook for 20 minutes, then mash evenly.

[0051] 4. Lactic acid bacteria fermentation: inoculate 2 g of lactic acid bacteria powder into the crushed material obtained in step 3, and after anaerobic fermentation at 38° C. for 4 hours, beat the fermented material, remove seeds, and filter with a filter screen (20 mesh).

[0052] 5. Spreading slices: Pour the fruit pulp filtered in step 4 on the tin foil, fix th...

Embodiment 2

[0093] Embodiment 2, lactic acid bacteria fermentation functional oligosaccharide hawthorn fruit paeonol

[0094] 1. Preparation of lactic acid bacteria fermented konjac mannan oligosaccharides and hawthorn fruit paeonol

[0095]1. Raw material pretreatment: choose 100g fresh hawthorn as raw material, wash and drain.

[0096] 2. Deployment: 35g konjac mannan oligosaccharide (purchased from Xi'an Yuansen Biotechnology Co., Ltd., CAS 37220-17-0) and 35g xylitol (purchased from Shandong Futian Pharmaceutical Co., Ltd., CAS 63-42- 3) Put it into 55g of water, fully dissolve it and add the hawthorn fruit processed in step 1.

[0097] 3. Fruit steaming and pulping: Pour the blended materials obtained in step 2 into a container, put the container in a pressure cooker (with a pressure of 70kpa, add 300g of water into the pot) and cook for 25 minutes, then mash evenly.

[0098] 4. Lactic acid bacteria fermentation: inoculate 3 g of lactic acid bacteria powder into the crushed materia...

Embodiment 3

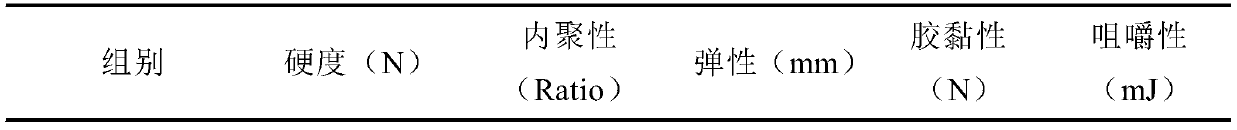

[0130] Embodiment 3, Lactobacillus plantarum fermentation functional oligosaccharide Hawthorn Danpi

[0131] The preparation method provided by a kind of lactobacillus plantarum fermented functional oligosaccharide hawthorn fruit peel provided by embodiment 3 is basically consistent with the preparation method provided by example 2, the difference is: adopt 3g lactobacillus plantarum powder (10 billion live bacteria / g, purchased from Xi'an Xinshan Biotechnology Co., Ltd., the product number is xs-0103) to replace 3g of lactic acid bacteria powder. The sensory qualities of the prepared Lactobacillus plantarum fermented functional oligosaccharide hawthorn peel had no significant difference (P>0.05) in the color, texture and taste of the traditional hawthorn peel, and the texture and color difference were similar to the traditional hawthorn peel. The moisture, ash, total sugar content and microbial indicators of the functional oligosaccharides fermented by Lactobacillus plantarum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com