Intermediate infrared nonlinear optical crystal POC and preparation method thereof

A nonlinear optics and crystal technology, applied in nonlinear optics, chemical instruments and methods, optics, etc., can solve the problems of crystal application limitations, difficulty in obtaining high-quality crystals, low laser damage threshold, etc., and achieve stable furnace temperature field, High laser damage threshold, effect of reducing segregation of melt components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

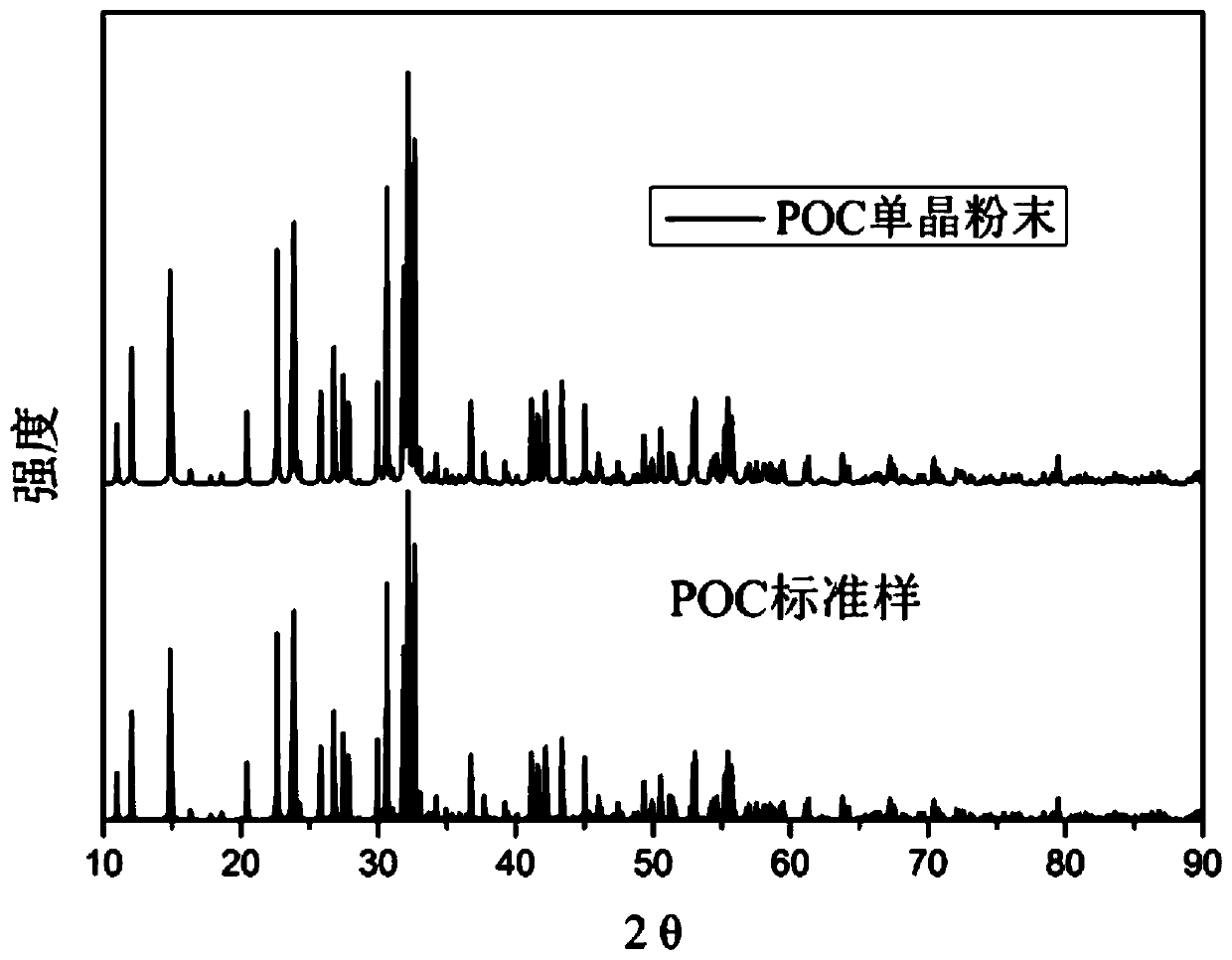

[0027] Using PbO and PbCl 2 As the initial raw material, put the initial raw material into the condition of 80° C. for 3 hours, and take it out after natural cooling. The dried raw material was divided according to PbO:PbCl 2 =8:9 mol ratio takes by weighing, and the medicine that weighs is placed in the agate mortar, grinds 2 hours; The powder after mixing is packed in the aluminum oxide crucible, adds a cover and places in the muffle furnace, in It was kept at 420°C for 48 hours, cooled naturally to room temperature, taken out, and fully ground to obtain a POC polycrystalline material, which was analyzed by X-ray powder diffraction. Repeat the above steps to perform secondary sintering at 440°C. The powder diffraction pattern of the POC crystal synthesized by the second polycrystalline material is shown in figure 1 .

[0028] Put the ground POC polycrystalline material into the platinum crucible, place the charged crucible in the descending furnace, cover the upper openi...

Embodiment 2

[0030] Using PbO and PbCl 2 As the initial raw material, put the initial raw material into the condition of 85° C. and bake it for 4 hours, and take it out after natural cooling. The dried raw material was divided according to PbO:PbCl 2 = 8:9 molar ratio weighing, put the weighed drug in an agate mortar, grind for 1.5 hours; put the powder after mixing evenly into an alumina crucible, cover it and place it in a muffle furnace, and heat it at 430 ° C Under the conditions of heat preservation for 48 hours, naturally cooled to room temperature and then taken out, after fully grinding, the POC polycrystalline material was obtained.

[0031]Put the ground POC polycrystalline material into a platinum crucible, place the charged crucible in a descending furnace, cover the upper opening of the crucible, control the furnace temperature to 595°C, and raise the temperature slowly Temperature, when the bottom of the crucible reaches the melting point of POC, the crystal growth starts, ...

Embodiment 3

[0033] Using PbO and PbCl 2 As the initial raw material, put the initial raw material into the condition of 60° C. and bake it for 5 hours, and take it out after natural cooling. The dried raw material was divided according to PbO:PbCl 2 =8:9.5 molar ratio weighing, put the weighed medicine in an agate mortar, and grind for 1 hour; put the powder evenly mixed into an alumina crucible, cover it and place it in a muffle furnace, and heat it at 440°C Under the conditions of heat preservation for 48 hours, naturally cooled to room temperature and then taken out, after fully grinding, the POC polycrystalline material was obtained.

[0034] Put the ground POC polycrystalline material into a platinum crucible, place the charged crucible in a descending furnace, cover the upper opening of the crucible, control the furnace temperature to 570°C, and raise the temperature slowly Temperature, when the bottom of the crucible reaches the melting point of POC, crystal growth begins, the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com