High ultraviolet reflection biological ceramic material

A bio-ceramic material, high-reflection technology, applied in nanotechnology and other directions, can solve the problem of metal-doped hydroxyapatite phase, morphology description of ultraviolet reflection ability, amorphous apatite structure instability, ultraviolet dissipation ability Not high problems, to achieve the effect of strong sunscreen timeliness, human safety, and conducive to reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 (the product is the best group of bioceramics: (10Zn bioceramics))

[0031] The chemical precipitation method is used to prepare bioceramic materials with high ultraviolet reflection. The specific operation steps are as follows:

[0032] (1) Preparation of chemical reagents

[0033] The chemical reagents used in the present invention are all analytically pure to ensure that no other impurities appear in the preparation process.

[0034] (2) Reaction solution configuration

[0035] (a) Zn(NO) 3 ) 2 and Ca(NO 3 ) 2 According to the molar ratio of 10:90, it is dissolved in deionized water, and it is formulated to contain Ca. 2+ / Zn 2+ The mixed solution is placed in a container and stirred evenly;

[0036] (b) take (NH 4 ) 2 HPO 4 Dissolved in deionized water, formulated with PO4 3- The solution. with NH 3 H 2 O adjust its solution to PH=10, for subsequent use;

[0037] (3) Zinc doping reaction

[0038] (a) in the above step (2) Ca 2+ / Zn 2+ Th...

Embodiment 2

[0048] Example 2 ((5Zn bioceramic))

[0049] Wherein Zn / Ca=5:95 (x is 0.5), (Zn+Ca) / P=1.67, the ratios are all molar ratios, and the remaining steps are as in Example 1. The obtained zinc-doped calcium-phosphorus bioceramic has an incomplete amorphous structure with a crystallinity of 40%, a needle-like micromorphology, an average particle size of 100-200 nm, and an average UVA and UVB reflectance of nearly 100. %, the average UVC reflectance is about 70%.

[0050] Example 3 (20Zn bioceramic)

[0051] It was prepared by sol-gel method with Ca(NO 3 ) 2 , P 2 O 5 and Zn(NO 3 ) 2 As a reactant, wherein Zn / Ca=20:80 (x is 2), (Zn+Ca) / P=1.67, the ratios are all molar ratios. put P 2 O 5 The solution was slowly added dropwise to Zn(NO 3 ) 2 and Ca(NO 3 ) 2 In the mixed solution of , the reaction temperature was 60 °C for 24 h, and then washed, dried and ground. The obtained powder was calcined at 400 °C for 2 h to obtain the desired sample. The obtained zinc-doped cal...

Embodiment 4

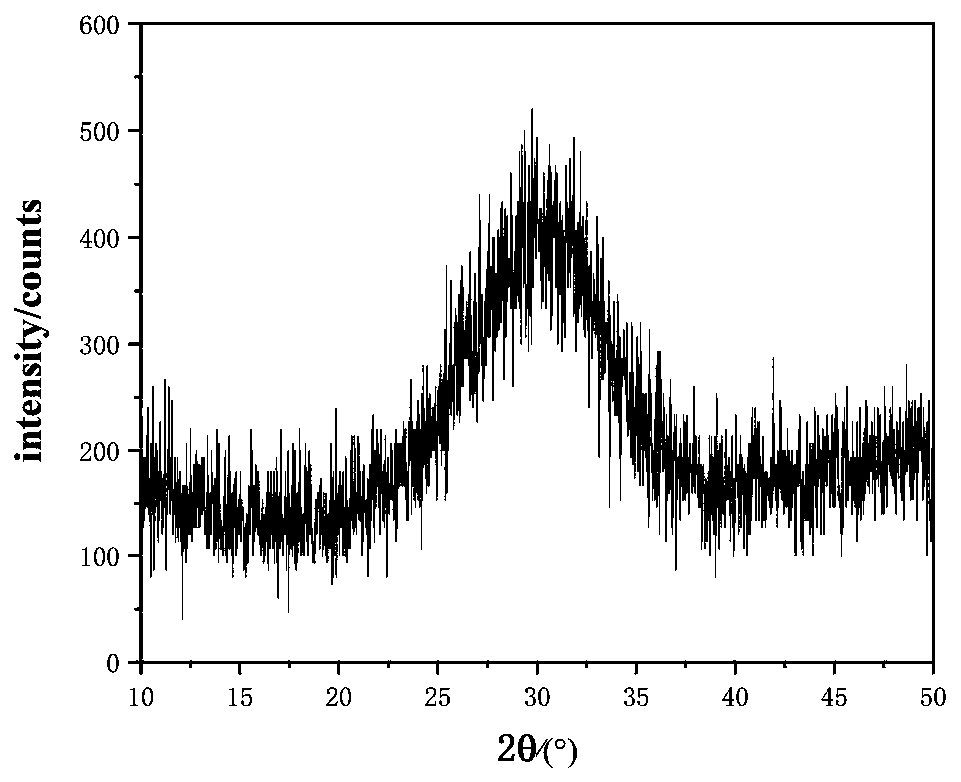

[0052] Example 4: Ultraviolet Emissivity Test

[0053] Samples were tested for UV reflectance using a UV-Vis photometer with an integrating sphere. Using barium sulfate as a reference sample, the products of Examples 1-3, nano-TiO 2 Carry out sample preparation in moulds with two groups of commercially available sunscreen products respectively, and each above-mentioned sample is loaded into a disc-shaped mould, and pressed with a plexiglass cylinder to obtain a test sample with a flat surface, then placed in an instrument, and a wavelength range (200 -400nm) for testing, and finally the UV reflectance data of the tested sample can be obtained. It can be seen from the figure that the ultraviolet reflectance of the product of the present invention is much higher than that of other groups.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com