Acrylate polymer emulsion and application thereof in preparation of silicate coating

A technology of polymer emulsion and acrylate, applied in the direction of alkali metal silicate paint, coating, etc., can solve the problems of affecting paint construction performance, long drying time of coating film, inconvenience for users, etc., and achieves low pollution and normal appearance , the effect of appearance without peculiar smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

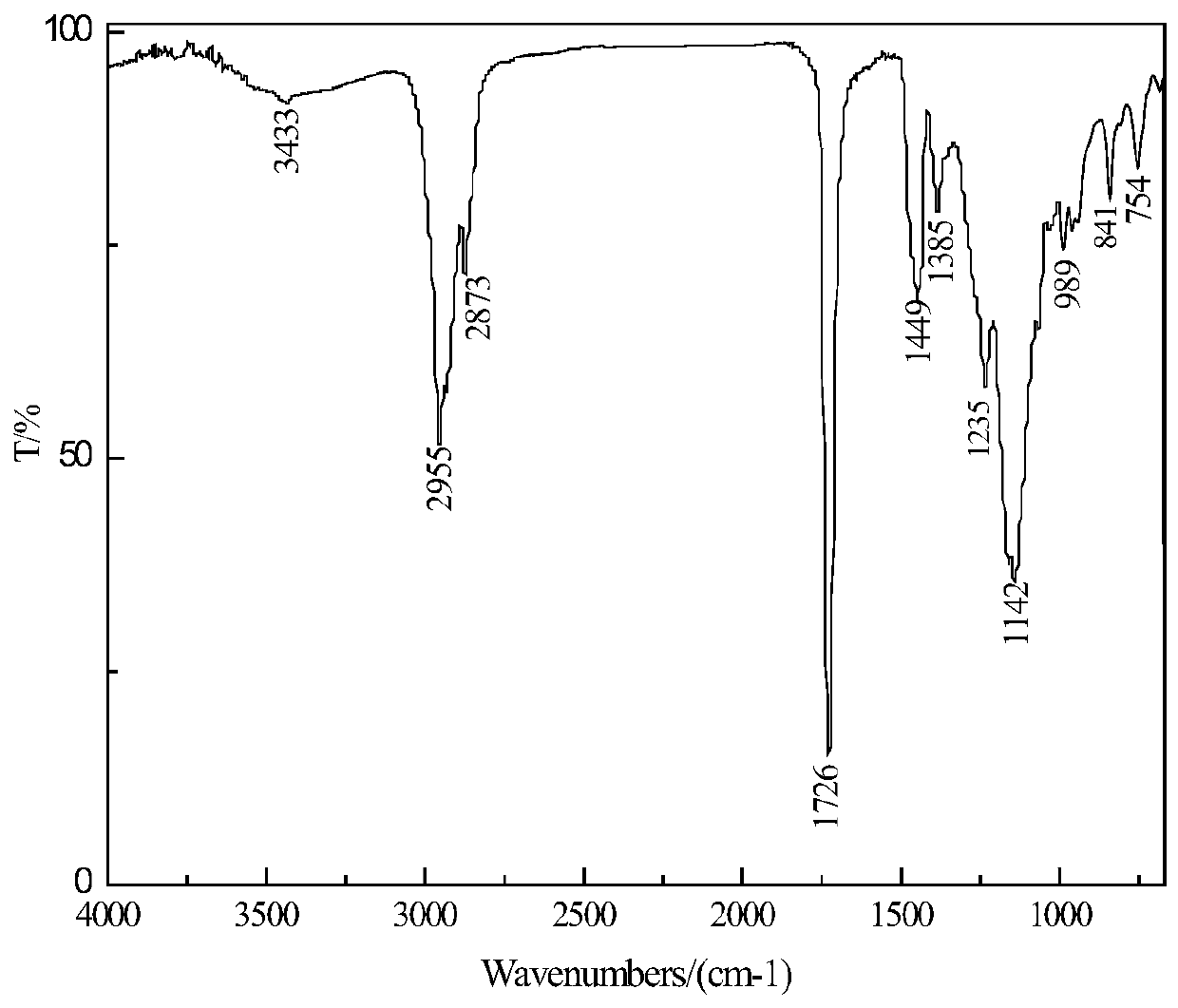

[0036] 1. Acrylate polymer emulsion

[0037] The mass composition of acrylate polymer emulsion: 14.4% of methyl methacrylate, 14.4% of butyl acrylate, 1.2% of N,N-diethylacrylamide, 0.21% of potassium persulfate, branched chain alkyl alcohol polyether sulfate ( ES-730) 1.2%, Alcohol Ether Glycoside (AEG) 0.6%, the balance is water, the total addition amount is 100%.

[0038] In a 250mL four-necked flask equipped with a reflux condenser, dropping funnel, and stirrer, add 0.60g of alcohol ether glycoside (AEG) and 1.20g of branched chain alkyl alcohol polyether sulfate (ES-730) and 38.20g of deionized water, stir and warm the water bath to 80 °C. Add 3.0 g of mixed monomers and 3.0 g of potassium persulfate (KPS) aqueous solution dropwise within 15 minutes respectively, and continue to insulate for 15 minutes after the dropwise addition is completed. Then the remaining 27.0g of KPS aqueous solution and 27.0g of mixed monomers were added dropwise into the four-neck flask within...

Embodiment 2

[0052] 1. Acrylate polymer emulsion

[0053] Quality composition of acrylate polymer emulsion: 14.25% of methyl methacrylate, 14.25% of butyl acrylate, 1.5% of N,N-diethylacrylamide, 0.21% of potassium persulfate, branched chain alkyl alcohol polyether sulfate ( ES-730) 0.9%, Alcohol Ether Glycoside (AEG) 0.9%, the balance is water, the total amount of feed is 100%.

[0054] In a 250mL four-neck flask equipped with a reflux condenser, dropping funnel, and stirrer, add 0.90g of alcohol ether glycoside (AEG) and 0.90g of branched chain alkyl alcohol polyether sulfate (ES-730) and 38.20g of deionized water, stir and warm the water bath to 80 °C. 3.0 g of mixed monomers and 3.0 g of potassium persulfate (KPS) aqueous solution were added dropwise within 15 minutes, and the temperature was continued for 15 minutes after the dropwise addition was completed. Then the remaining 27.0g of KPS aqueous solution and 27.0g of mixed monomers were added dropwise into the four-neck flask with...

Embodiment 3

[0063] 1. Acrylate polymer emulsion

[0064] The mass composition of acrylate polymer emulsion: methyl methacrylate 14.1%, butyl acrylate 14.1%, N,N-diethylacrylamide 1.8%, potassium persulfate 0.21%, branched alkyl alcohol polyether sulfate ( ES-730) 0.6%, alcohol ether glycoside (AEG) 1.2%, the balance is water, and the total feeding amount is 100%.

[0065] In a 250mL four-necked flask equipped with a reflux condenser, a dropping funnel, and a stirrer, add 1.20g of alcohol ether glucoside (AEG) and 0.60g of branched alkyl alcohol polyether sulfate (ES-730) and 38.20g of 3.0g of mixed monomer and 3.0g of potassium persulfate (KPS) aqueous solution were added dropwise within 15min respectively, and the temperature was maintained for 15min after the dropwise addition; then the remaining 27.0g The KPS aqueous solution and 27.0 g of mixed monomers were added dropwise to the four-necked flask within 3.0 h, and after the dropping was completed, the temperature was raised to 90° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

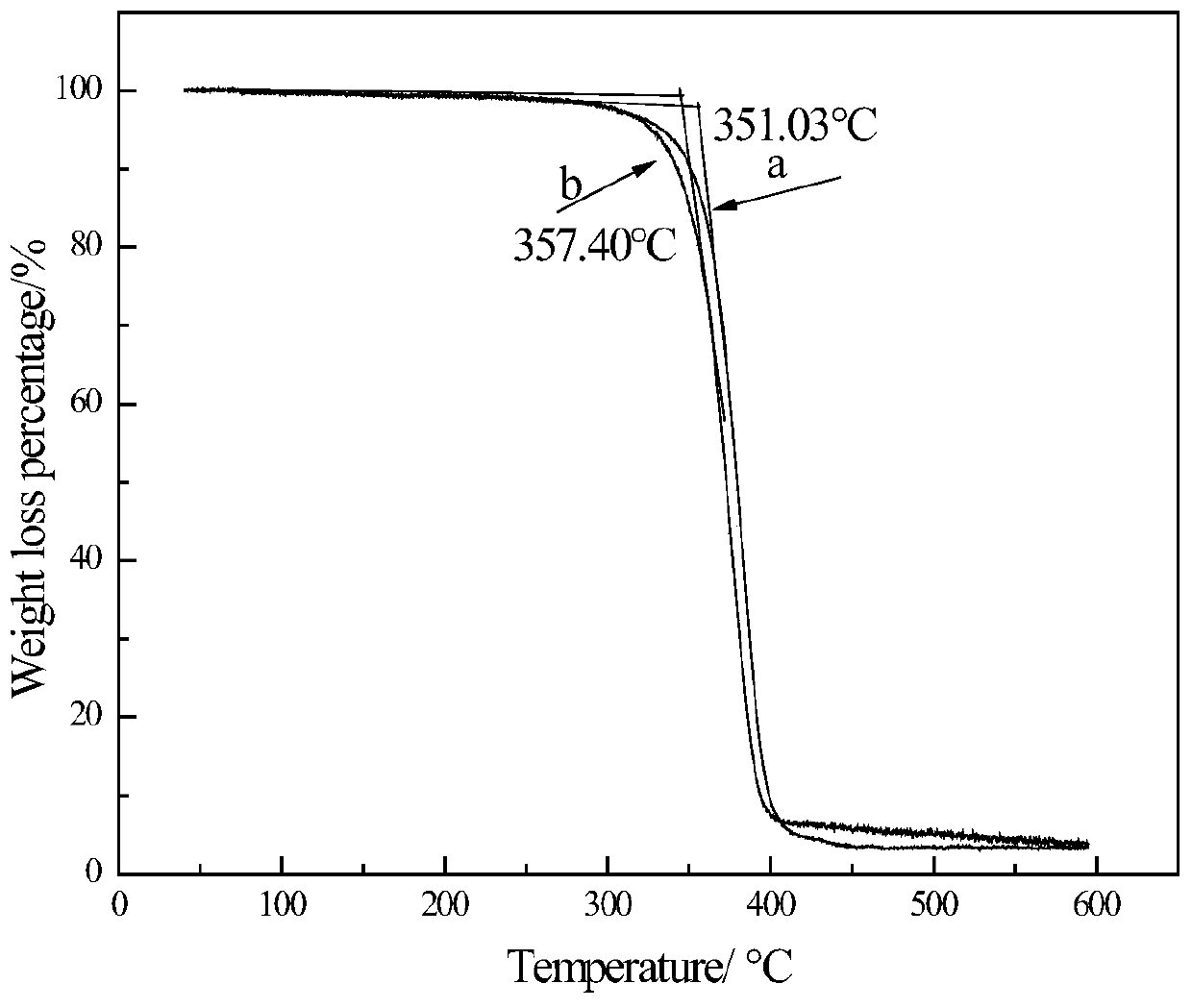

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com