Magnesium-modified spherical calcium-based thermochemical energy storage material and preparation method thereof

A technology of energy storage materials and small balls, which is applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of high price, complicated production methods, and difficult access to raw materials, so as to achieve widespread existence in nature and easy large-scale acquisition , Energy storage performance and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The difference between the preparation steps of this Example 1 and Comparative Example 1 is: cooling the carbonized black solid to room temperature, adding an appropriate amount of deionized water, placing it in an extruder, extruding a strip-shaped solid, and then placing the strip-shaped solid Spherical particles were made in a rolling ball machine; then the spherical particles were put into a muffle furnace and calcined at a constant temperature in an air atmosphere at a calcination temperature of 800°C, a heating rate of 10°C / min, and a calcination time of 2h.

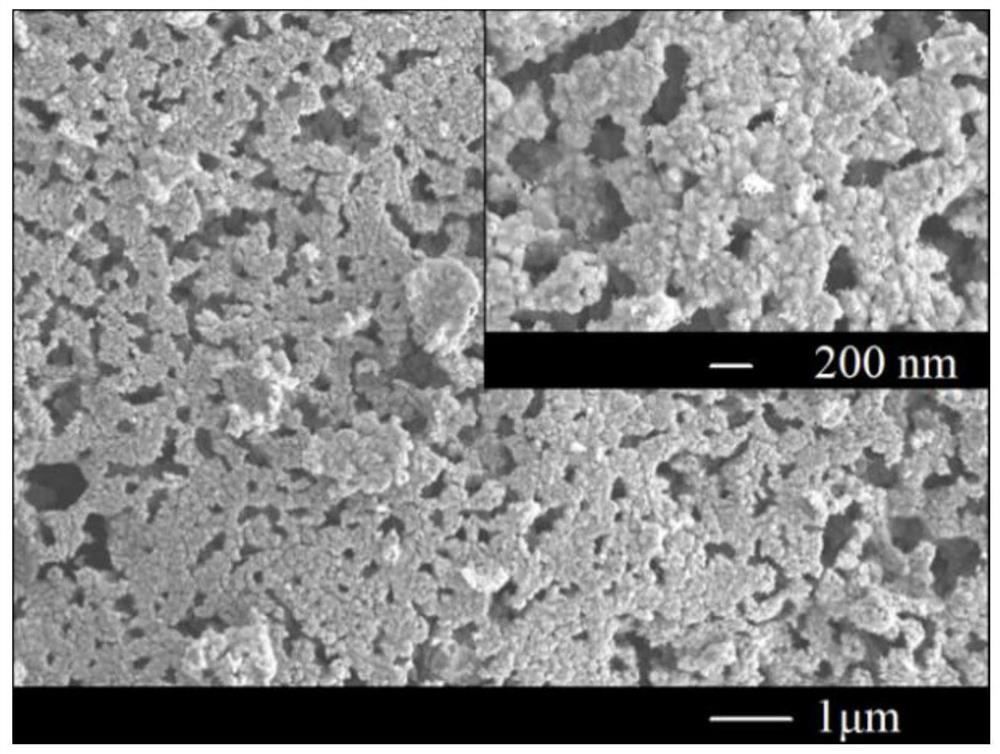

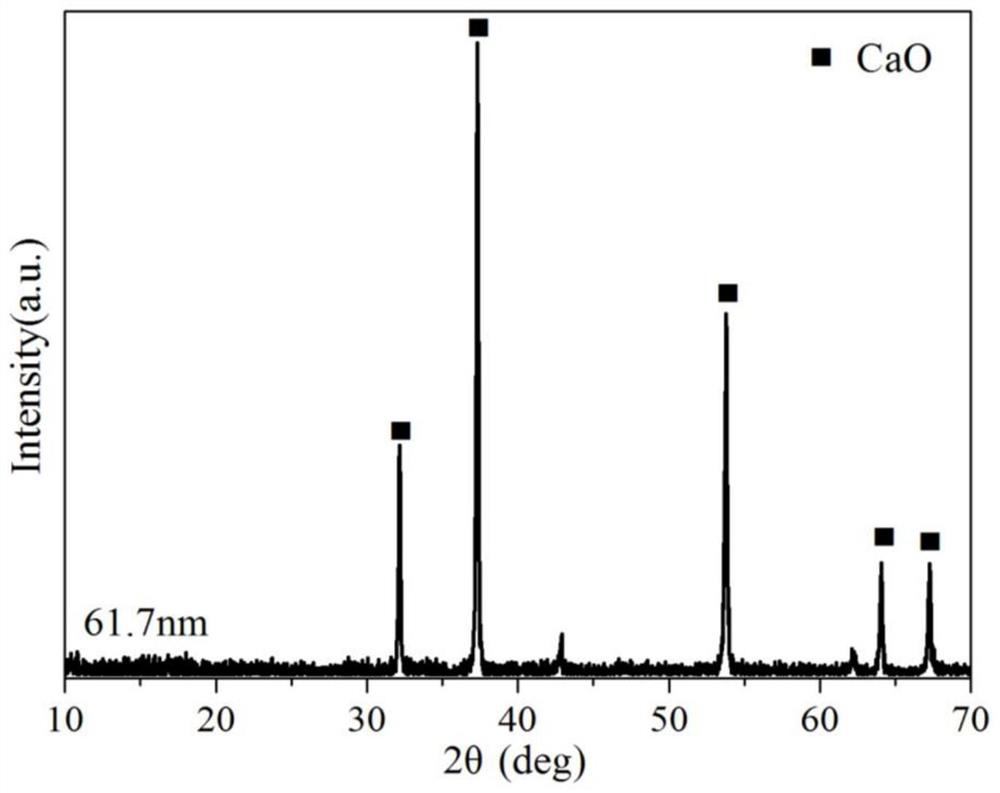

[0042] The energy storage material obtained in the embodiment was observed under a scanning electron microscope, and the results were as follows: figure 2 As shown, it can be observed that although the energy storage material prepared in Example 1 is extruded into balls, it maintains a more stable macroporous skeleton structure. Obtain the crystal phase composition of the sample in the 2θ range of 10-90 ° b...

Embodiment 2

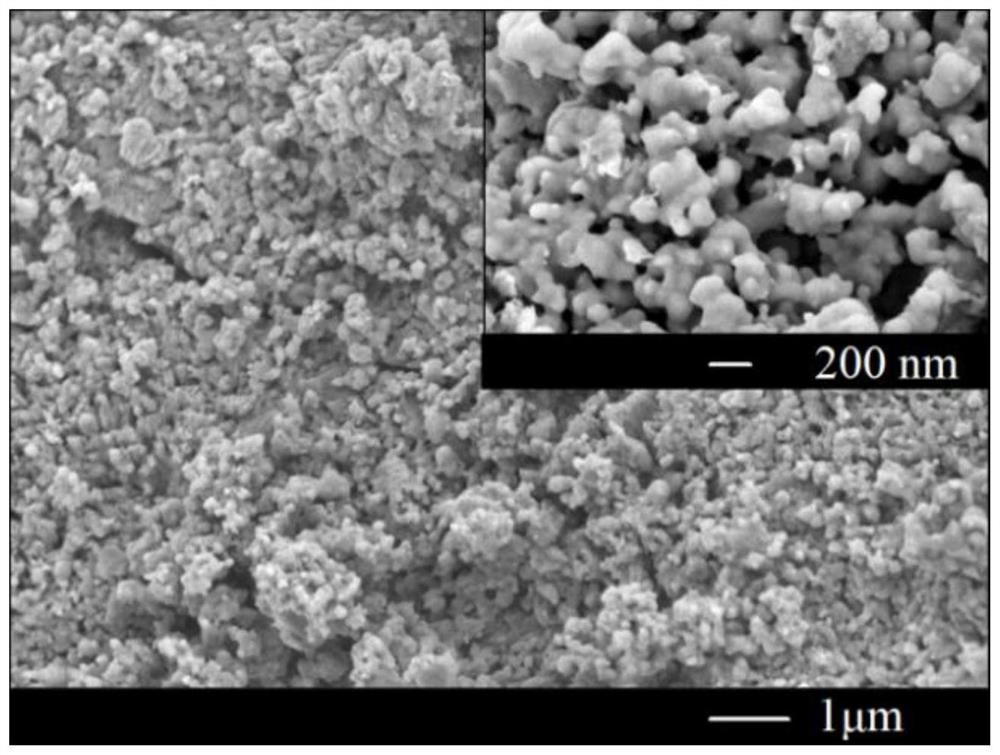

[0056] Weigh 3g calcium nitrate (Ca(NO 3 ) 2 ) and 0.3619g magnesium nitrate (Mg(NO 3 ) 2 ) (that is, the molar ratio of calcium nitrate and magnesium nitrate is 9:1), placed in an agate mortar, fully ground and mixed; the uniformly mixed calcium nitrate and magnesium nitrate mixture is put into a corundum crucible, placed in a muffle furnace, Calcination in air atmosphere, the calcination temperature is 900°C, the heating rate is 20°C / min, and the calcination time is 1h, to obtain a white solid powder, which is taken out and cooled to room temperature.

[0057] Weigh 2.0763g of citric acid (i.e. calcium oxide, magnesium oxide, citric acid molar ratio CaO: MgO: CA=9:1:7), add in the white solid powder, fully mix, then place the blended mixture In a tube furnace, constant temperature carbonization was carried out under a nitrogen atmosphere, the carbonization temperature was 500°C, the heating rate was 20°C / min, and the carbonization time was 2h to obtain a fluffy black soli...

Embodiment 3

[0060] Weigh 3g of calcium acetate (Ca(CH 3 COO) 2 ) and 0.1917g magnesium carbonate (MgCO 3 ) (that is, the molar ratio of calcium acetate and magnesium carbonate is 9:1), placed in an agate mortar, fully ground and mixed; put the uniformly mixed calcium nitrate and magnesium nitrate mixture into a corundum crucible, placed in a muffle furnace, Calcination in air atmosphere, the calcination temperature is 850°C, the heating rate is 10°C / min, and the calcination time is 2h, to obtain a white solid powder, which is taken out and cooled to room temperature.

[0061] Weigh 2.7831g of citric acid (i.e. calcium oxide, magnesium oxide, citric acid molar ratio CaO: MgO: CA=9:1:7), add in the white solid powder, fully mix, then place the blended mixture In a tube furnace, constant temperature carbonization was carried out under a nitrogen atmosphere, the carbonization temperature was 400°C, the heating rate was 10°C / min, and the carbonization time was 1h to obtain a fluffy black sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com