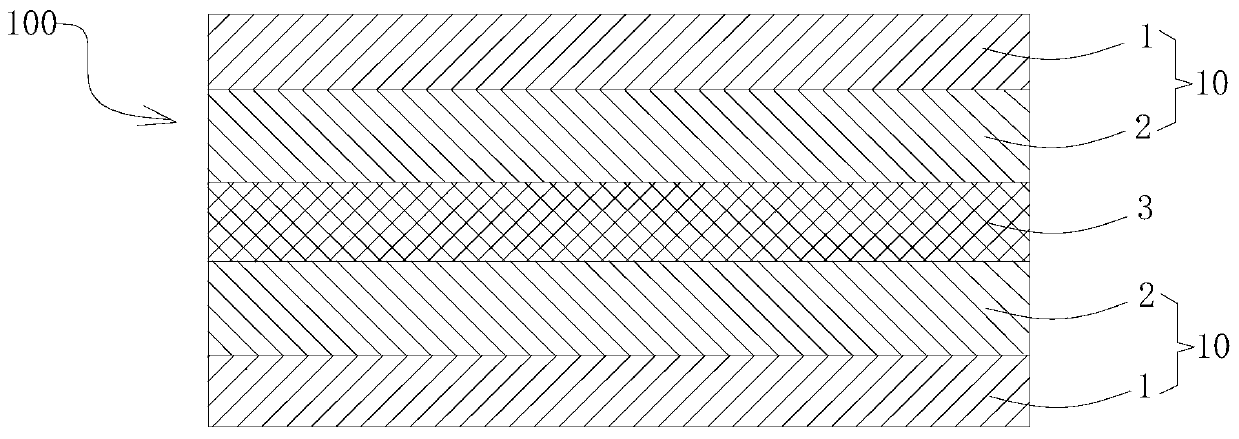

High-frequency low-loss adhesive-free flexible copper-clad plate and manufacturing method thereof

A production method and low-loss technology, applied in chemical instruments and methods, printed circuit manufacturing, circuit substrate materials, etc., can solve the problem of large linear expansion coefficient, no adhesion of polytetrafluoroethylene resin, and inability to apply flexible copper clad laminates And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

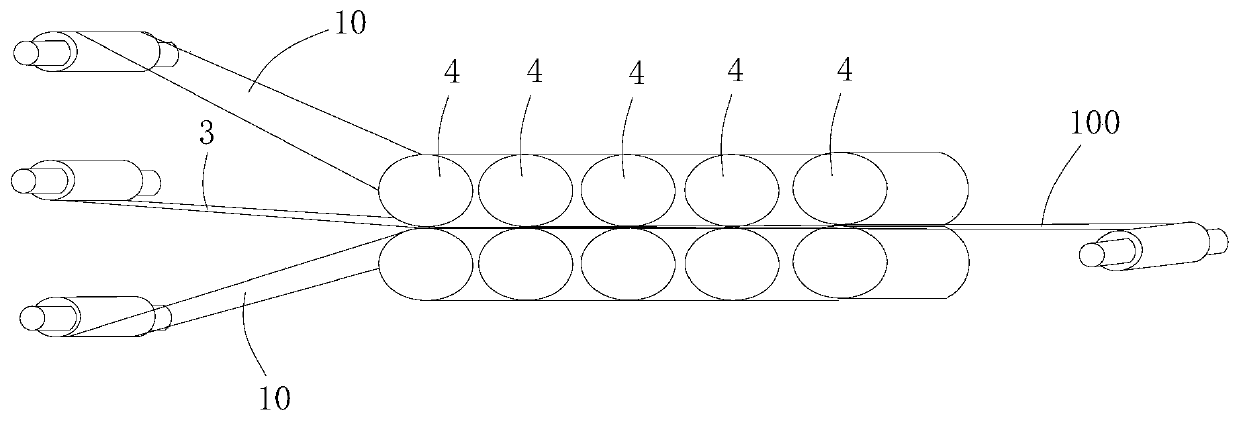

Method used

Image

Examples

Embodiment 1

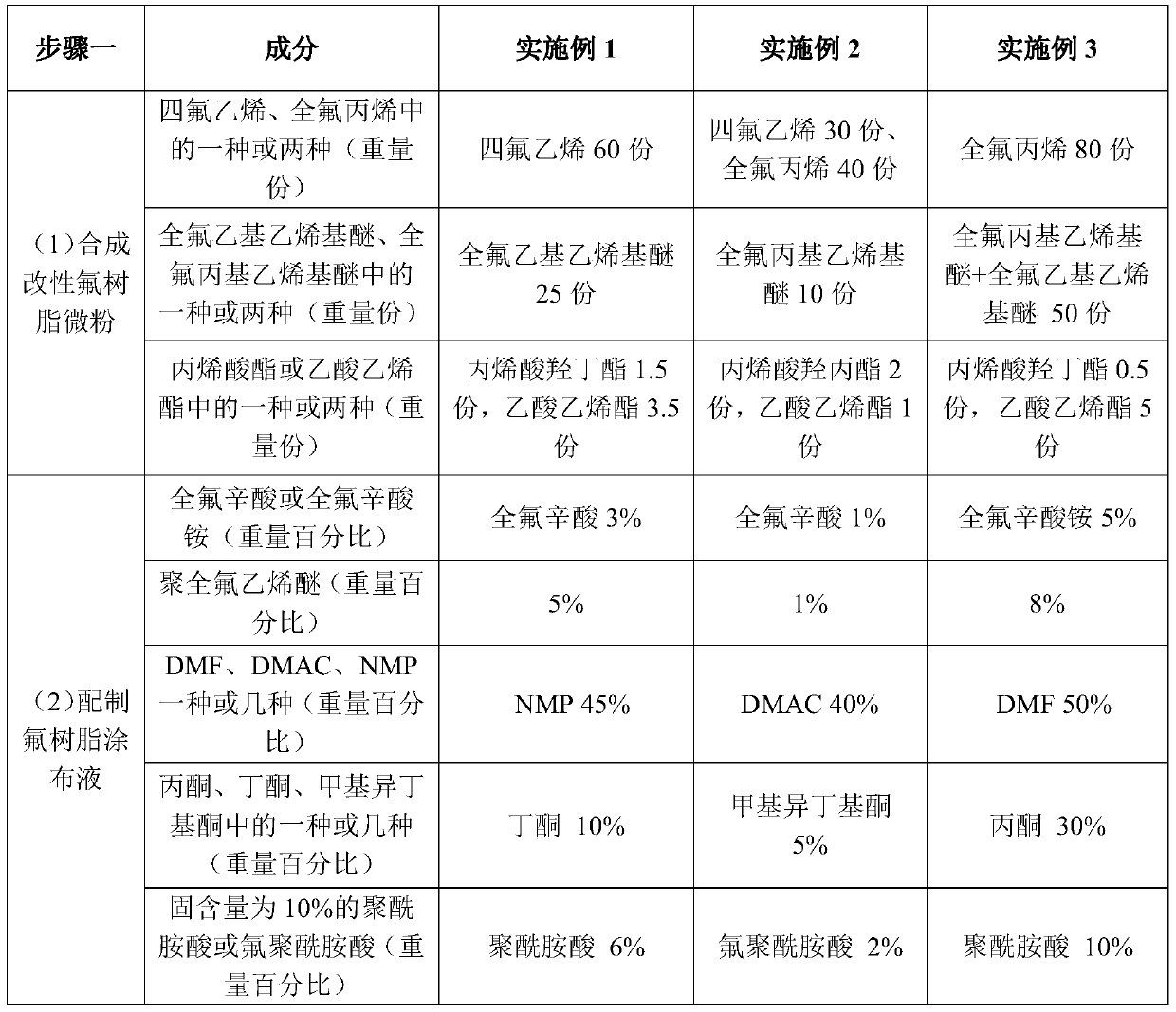

[0063] Step 1, preparing fluororesin coating solution;

[0064] (1) Take 60kg of tetrafluoroethylene, 25kg of perfluoroethyl vinyl ether, 1.5kg of hydroxybutyl acrylate, and 3.5kg of vinyl acetate, and obtain fluororesin micropowder after emulsion polymerization and demulsification.

[0065] (2) Add 3% perfluorooctanoic acid, 5% polyperfluoroethylene ether, and 40% NMP to the fluororesin micropowder prepared in (1) above, stir at high speed for 2 hours, and disperse for 2 hours with a homogenizer to obtain fluorine Resin emulsion: Add 10% methyl ethyl ketone and 6% polyamic acid with a solid content of 10% according to the weight percentage of the fluororesin emulsion to dissolve, stir and disperse evenly to obtain a fluororesin coating liquid.

[0066] Step 2, making fluororesin composite material;

[0067] Apply the fluororesin coating solution prepared in step 1 evenly on the surface of 12μm copper foil, dry at a speed of 4m / min, and a temperature of 80-240°C, and wind it ...

Embodiment 2

[0071] Step 1, preparing fluororesin coating solution;

[0072] (1) Get 30kg of tetrafluoroethylene, 40kg of perfluoropropylene, 40kg of perfluoropropylene, 10kg of perfluoropropyl vinyl ether, 2kg of hydroxypropyl acrylate, and 1kg of vinyl acetate, and obtain fluororesin micropowder after emulsion polymerization and demulsification.

[0073] (2) Add 1% perfluorooctanoic acid, 1% polyperfluoroethylene ether, and 40% DMAC by weight percentage to the fluororesin micropowder prepared in the above (1), stir at high speed for 2 hours, and disperse for 2 hours with a homogenizer to obtain fluorine Resin emulsion: Add 5% methyl isobutyl ketone and 2% fluoropolyamic acid with a solid content of 10% according to the weight percentage of the fluororesin emulsion to dissolve, stir and disperse evenly to obtain a fluororesin coating liquid.

[0074] Step 2, making fluororesin composite material;

[0075] Apply the fluororesin coating solution prepared in step 1 evenly on the surface of ...

Embodiment 3

[0079] Step 1, preparing fluororesin coating solution;

[0080] (1) Get 80kg of perfluoropropylene, 50kg of perfluoropropyl vinyl ether and perfluoroethyl vinyl ether, 0.5kg of hydroxybutyl acrylate, and 5kg of vinyl acetate to obtain fluororesin micropowder after emulsion polymerization and demulsification.

[0081] (2) Add 5% ammonium perfluorooctanoate, 8% polyperfluoroethylene ether, and 50% DMF to the fluororesin micropowder prepared in the above (1) by weight percentage, stir at high speed for 2 hours, and disperse for 2 hours with a homogenizer to obtain Fluororesin emulsion; then add 30% acetone and 10% polyamic acid with a solid content of 10% according to the weight percentage of the fluororesin emulsion to dissolve, stir and disperse evenly to obtain a fluororesin coating liquid.

[0082] Step 2, making fluororesin composite material;

[0083] Apply the fluororesin coating solution prepared in step 1 evenly on the surface of 12μm copper foil, dry at a speed of 4m / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com