Preparation method and application of bimetal organic framework composite material

A composite material and organic framework technology, applied in biochemical fuel cells, electrical components, battery electrodes, etc., can solve the problems of inability to connect porous carbon, easy to fall off, unfavorable oxygen adsorption and desorption, etc., to achieve excellent electrochemical performance and chemical Good stability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the bimetallic organic framework composite material of this embodiment comprises the following steps:

[0034] S1, 0.90gZn(NO 3 ) 2 •6H 2 O was dissolved in 30ml of methanol to obtain solution A; 1.0g of 2-methylimidazole was dissolved in 20ml of methanol to obtain solution B; under stirring, solution B was slowly added to solution A, stirred for 10min, at room temperature After standing still for 24 hours, centrifuge at 9000 rpm for 5 minutes to obtain a precipitate, wash the precipitate three times with methanol, and dry it at 60°C for 12 hours to obtain ZIF-8.

[0035] S2, 0.10g ZIF-8 was dissolved in 30ml methanol to obtain solution C; 0.30g 2-methylimidazole and 0.15g Co(NO 3 ) 2 •6H 2 O was dissolved in 10ml of methanol to obtain solution D; under stirring, solution D was slowly added to solution C, stirred for 10 minutes, left at room temperature for 24 hours, and then centrifuged at 9000 rpm for 5 minutes to obtain a precipitate, ...

Embodiment 2

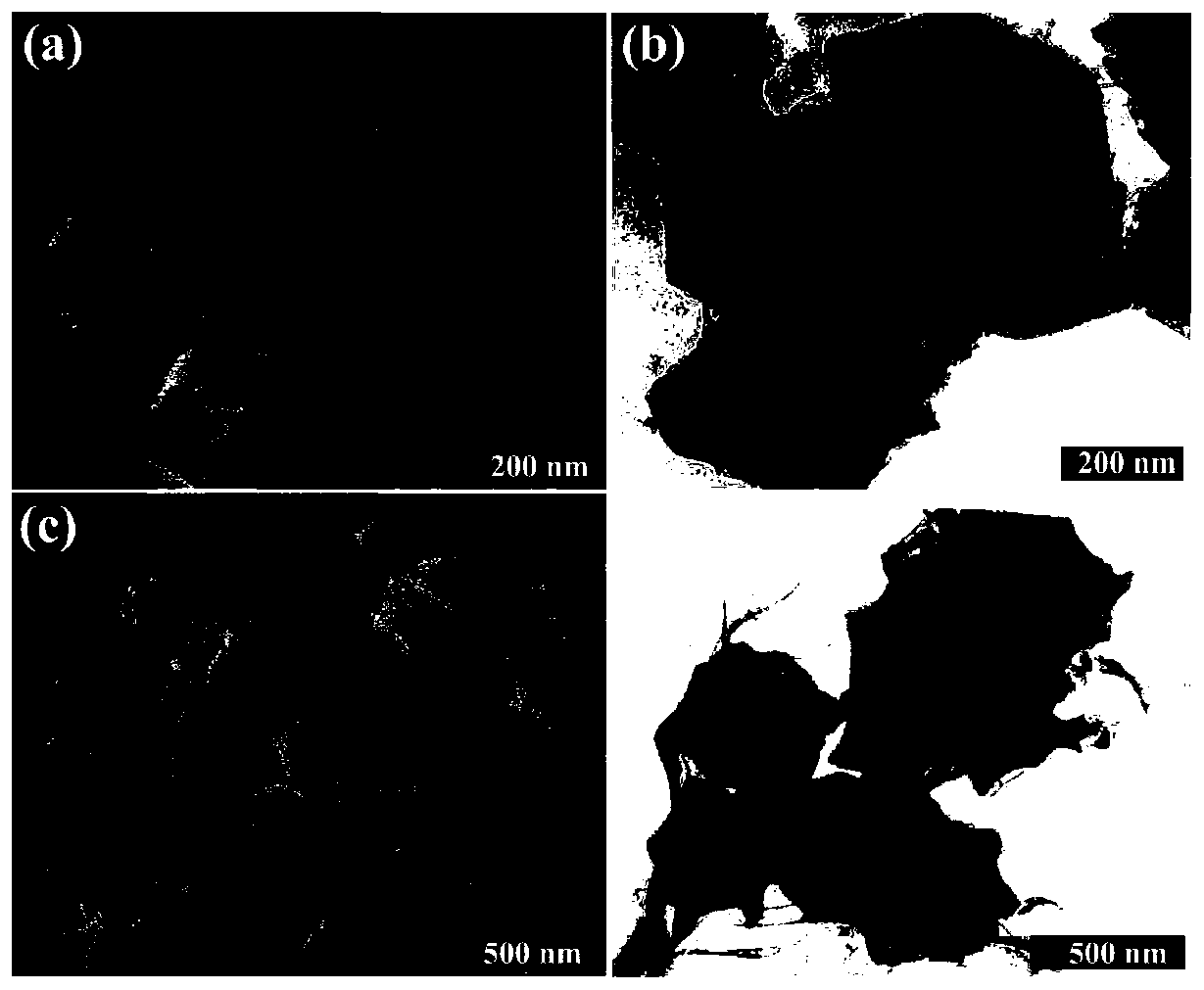

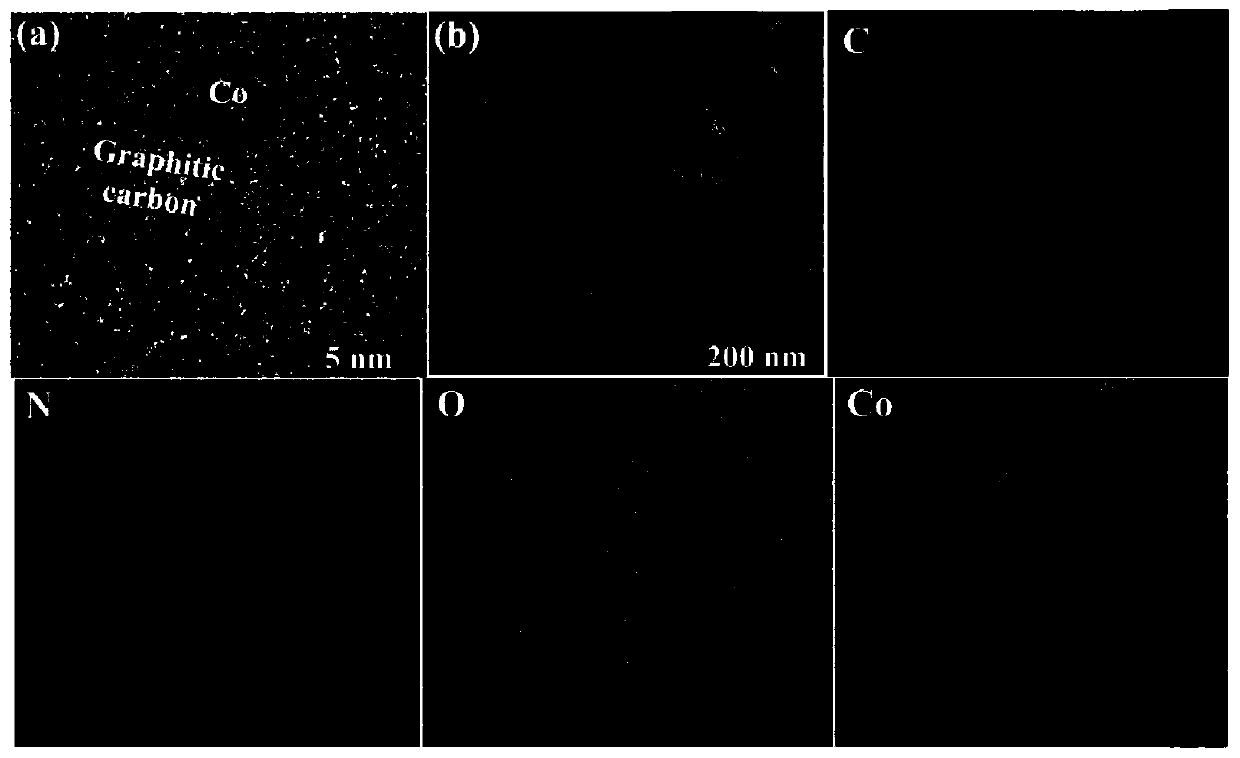

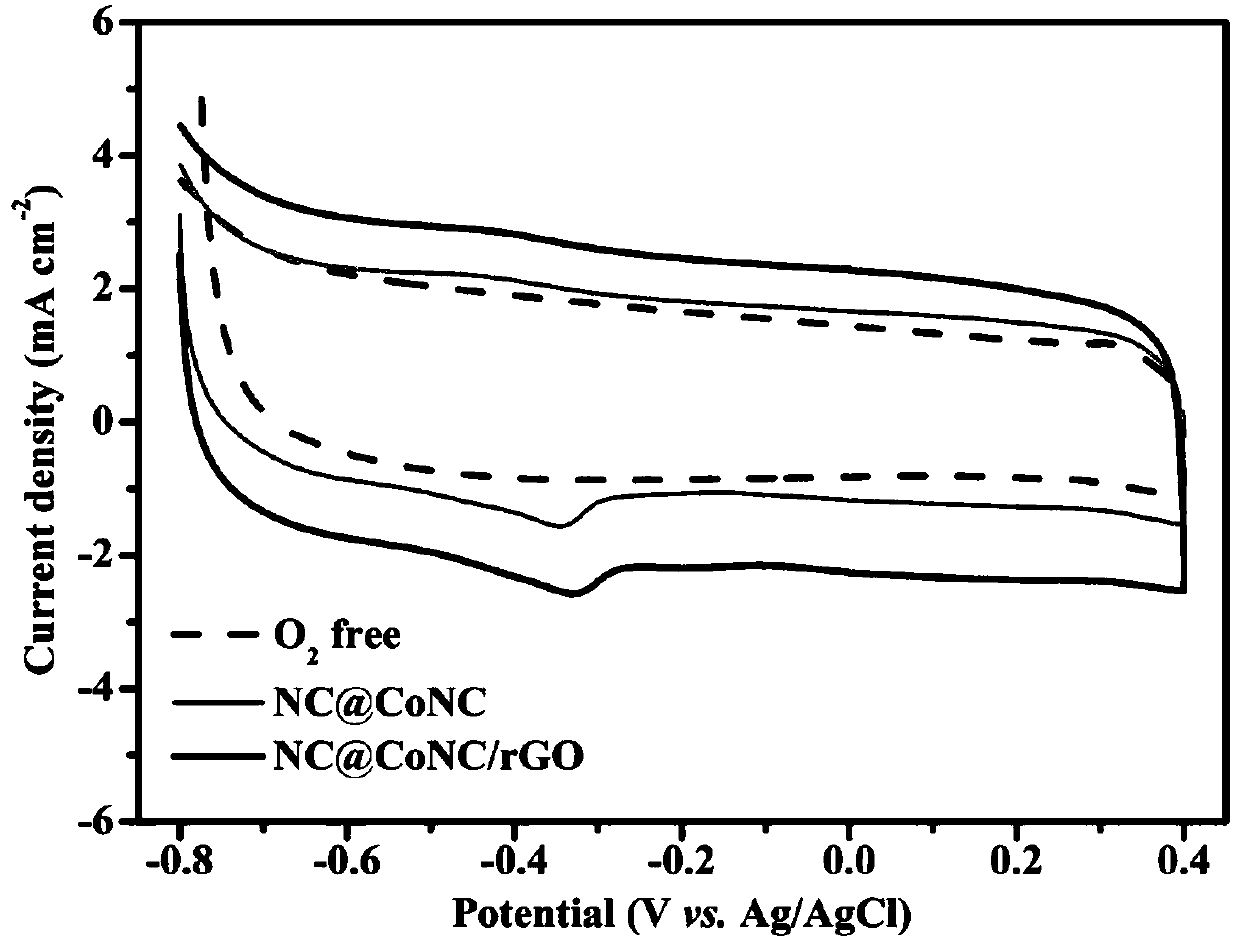

[0047] The difference between this example and Example 1 is that: Weigh 50 mg of acidified derivative porous carbon, mix with 10 mL PDDA aqueous solution, stir for 2 h, centrifuge (9000 rpm, 5 min), and use twice After washing with water for 3 times, 5 mL of graphene oxide (GO) with a concentration of 1.0 mg / mL was added, stirred for 6 h, washed with water for 3 times by centrifugation, and then freeze-dried in a tube furnace under Ar atmosphere at 900 °C ( 3°C / min) high temperature annealing for 2 h, the target product NC@CoNC / rGO-5 composite nanomaterial was obtained, and the cathode polarization curve of the NC@CoNC / rGO-5 composite nanomaterial when used as MFC cathode catalyst was as follows Figure 4 shown.

Embodiment 3

[0049] The difference between this example and Example 1 is that: Weigh 50 mg of acidified derivative porous carbon, mix with 10 mL PDDA aqueous solution, stir for 2 h, centrifuge (9000 rpm, 5 min), and use twice After washing with water for 3 times, 15 mL of graphene oxide (GO) with a concentration of 1.0 mg / mL was added, stirred for 6 h, centrifuged and washed 3 times with water, freeze-dried and placed in a tube furnace at 900 °C (3 ℃ / min) high-temperature annealing for 2 h to obtain the target product NC@CoNC / rGO-15 composite nanomaterial, and the cathode polarization curve of NC@CoNC / rGO-15 composite nanomaterial when used as MFC cathode catalyst, as shown in Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com