Copper-based metal surface tin immersion liquid and application thereof

A base metal, immersion tin technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the need of not achieving the flexibility of the coating, affecting the processing and use of circuit boards, signal transmission and stability. and other problems, to achieve the effect of improving activity and stability, high compactness, and maintaining solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

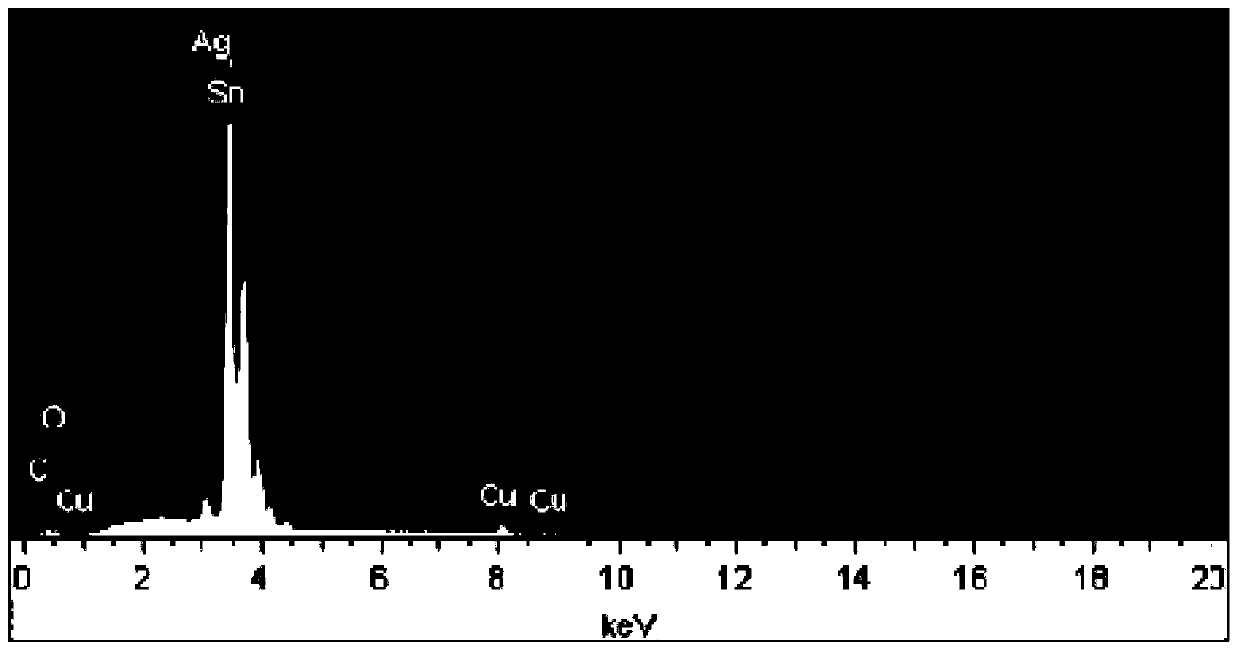

Image

Examples

Embodiment 1

[0070] This embodiment provides a kind of copper base metal surface immersion tin liquid, and the processing method of printed circuit board:

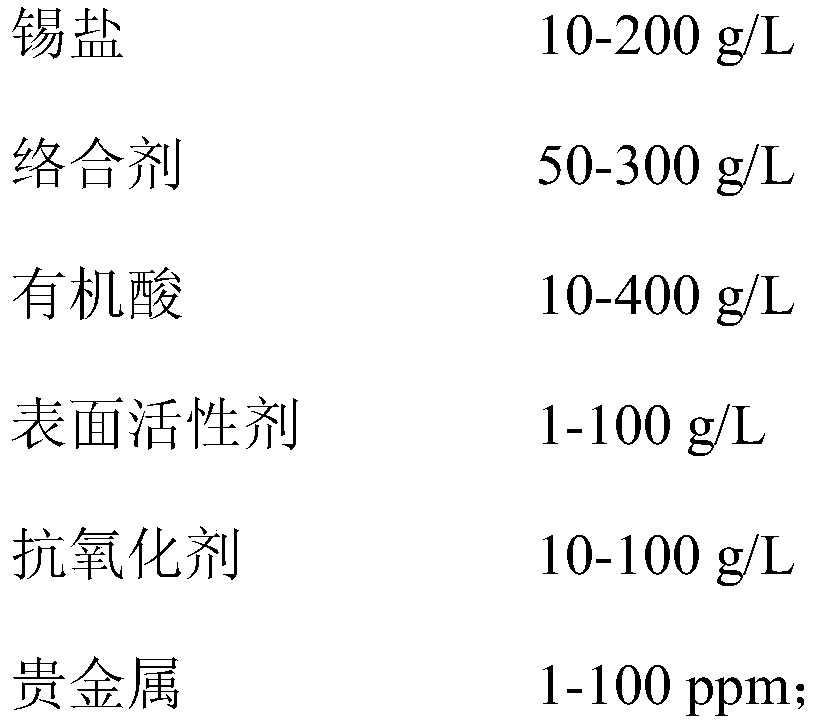

[0071] The copper-based metal surface immersion tin solution comprises the following components in terms of mass concentration:

[0072]

[0073] The processing method of the printed circuit board provided in this embodiment specifically includes the following steps:

[0074] (1) Pretreatment: At 60°C, immerse the printed circuit board in an acidic degreasing solution for 1 minute for degreasing treatment, and then at 40°C, use a microetching solution to immerse the printed circuit board for 2 minutes for microetching treatment , and control the amount of microetch to 1.2μm;

[0075] (2) Pre-soaking: place the printed circuit board pretreated in step (1) in the above-mentioned copper-based metal surface immersion tin solution for 2 minutes at 20°C, and form a 0.2 μm surface on the copper-based surface of the printed circuit board. ...

Embodiment 2

[0080] This embodiment provides a kind of copper base metal surface immersion tin liquid, and the processing method of printed circuit board:

[0081] The copper-based metal surface immersion tin solution comprises the following components in terms of mass concentration:

[0082]

[0083]

[0084] The processing method of the printed circuit board provided in this embodiment specifically includes the following steps:

[0085] (1) Pretreatment: At 40°C, immerse the printed circuit board in an acidic degreasing solution for 5 minutes for degreasing treatment, and then at 30°C, use a microetching solution for 5 minutes for microetching treatment , and control the amount of microetching to 1.5 μm;

[0086] (2) Pre-soaking: place the printed circuit board pretreated in step (1) in the above-mentioned copper-based metal surface immersion tin solution for 3 minutes at 20 ° C, and form a 0.3 μm copper-based surface on the printed circuit board. Pre-dipped tin coating;

[0087...

Embodiment 3

[0090] This embodiment provides a kind of copper base metal surface immersion tin liquid, and the processing method of printed circuit board:

[0091] The copper-based metal surface immersion tin solution comprises the following components in terms of mass concentration:

[0092]

[0093]

[0094] The processing method of the printed circuit board provided in this embodiment specifically includes the following steps:

[0095] (1) Pretreatment: At 40°C, immerse the printed circuit board in an acidic degreasing solution for 5 minutes for degreasing treatment, and then at 30°C, use a microetching solution for 5 minutes for microetching treatment , and control the amount of microetching to 1.5 μm;

[0096] (2) Pre-soaking: place the printed circuit board pretreated in step (1) in the above copper-based metal surface immersion tin solution for 1 min at 20°C, and form a 0.2 μm surface on the copper-based surface of the printed circuit board. Pre-dipped tin coating;

[0097]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com