Non-dyed regenerated polyester staple fiber preparation process

A preparation process, technology of recycled polyester, applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., can solve the problems of poor dyeing effect, agglomeration, and uneven dispersion of colored polyester fibers, achieve good dyeing effect, prevent mutual agglomeration, and disperse uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

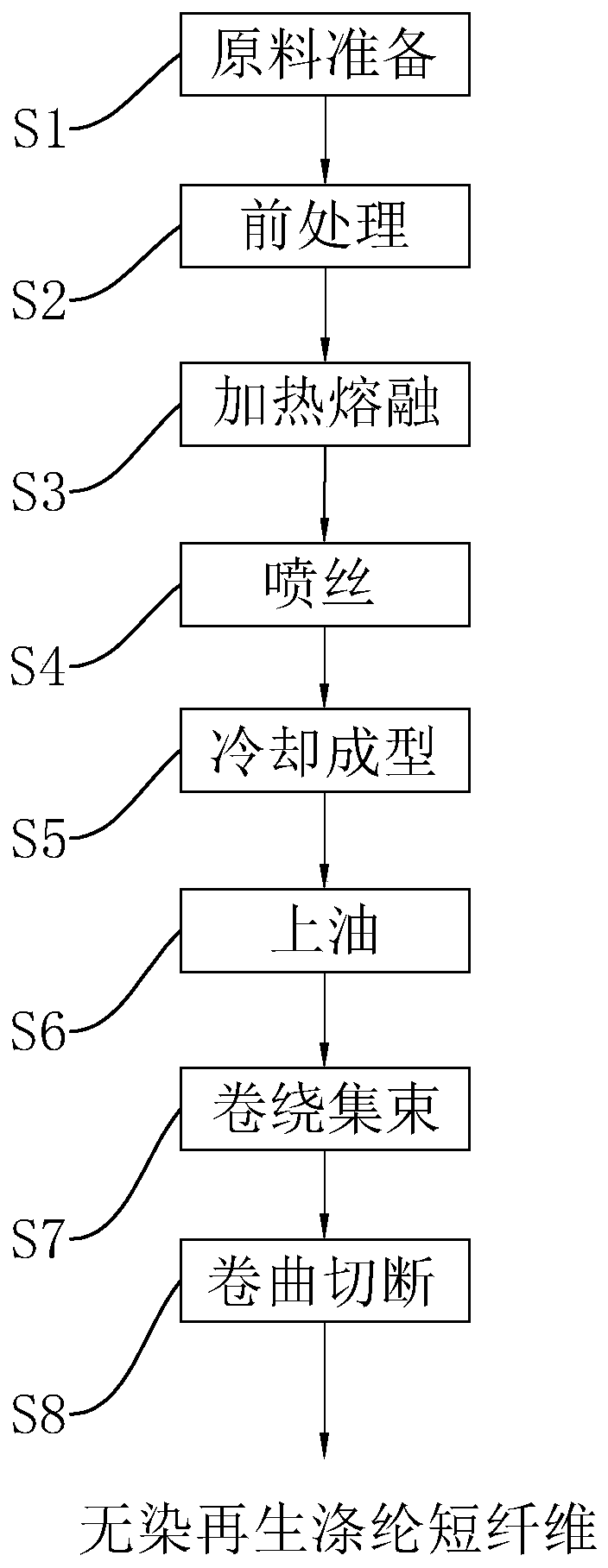

[0040] refer to figure 1 , a preparation process of non-dyed regenerated polyester staple fiber, the bottle flakes are subjected to the following steps:

[0041] S1: Raw material preparation. The bottle flakes of the recovered mineral water bottles are repeatedly cleaned, sterilized, and then cut and crushed.

[0042] S2: pre-processing. Sorting the materials after S1 treatment, and then put the materials into the rotary drum vacuum dryer. After the feeding is completed, start to heat up in the drum at a rate of 1.5°C / min, and heat up to 60°C for heat preservation. After that, heat transfer oil is introduced and the drum is started at the same time. At the same time, start the vacuum pump to evacuate the drum, and keep the vacuum at 70Pa, the drying time is 10h, and the moisture content of the bottle flakes is controlled below 0.01%.

[0043] S3: heating and melting.

[0044] First prepare the masterbatch. Put the raw materials of the masterbatch into the slurry tank in no...

Embodiment 24

[0071] Embodiment 24: The difference from Example 1 is that in the step of S6 oiling, the chemical composition of the oil agent is 33 parts by weight of stearylamine polyoxyethylene ether, 32 parts of lauryl alcohol and aminopropanol kojic acid phosphoric acid 51 parts of ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com