Decoration formaldehyde scavenger

A formaldehyde scavenger and deodorant technology, which is used in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems that the reaction conditions are difficult to reach suitable conditions, the furniture metal products are damaged, and the membrane is easily damaged, and the product is stable. Irreversible, easy to operate, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

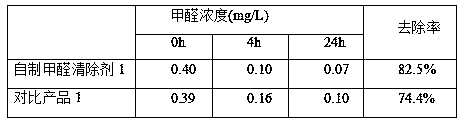

specific Embodiment approach 1

[0037] Self-made formaldehyde scavenger 1: Take 30.3g (about 200mmol) of diethyl malonate and 48g of CS / AC catalyst, add them into 1000g of water and mix them to prepare the formaldehyde scavenger 1 of the present invention.

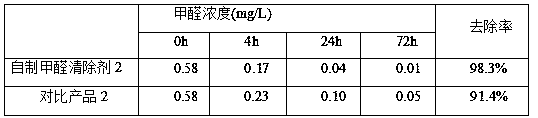

specific Embodiment approach 2

[0044] Self-made formaldehyde scavenger 2: Take about 500g of water, add 20g of carmellose, 15g of polyvinyl alcohol, 6g of fatty alcohol polyoxyethylene ether, and 10g of chitin in sequence under stirring, and weigh 25.8g of ethyl acetoacetate after stirring (about 200mmol), CS / AC catalyst 100g, stir until clear, make up water to 1000g, add 0.2g orange essence, mix well, and then the formaldehyde scavenger 2 of the present invention is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com