PVDF ultrafiltration membrane modified with visible light photocatalyst and preparation method and application thereof

A photocatalyst and nano-photocatalyst technology, applied in the field of PVDF ultrafiltration membrane and its preparation, achieves the effects of remarkable photocatalytic performance, avoiding photocorrosion and promoting visible light responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

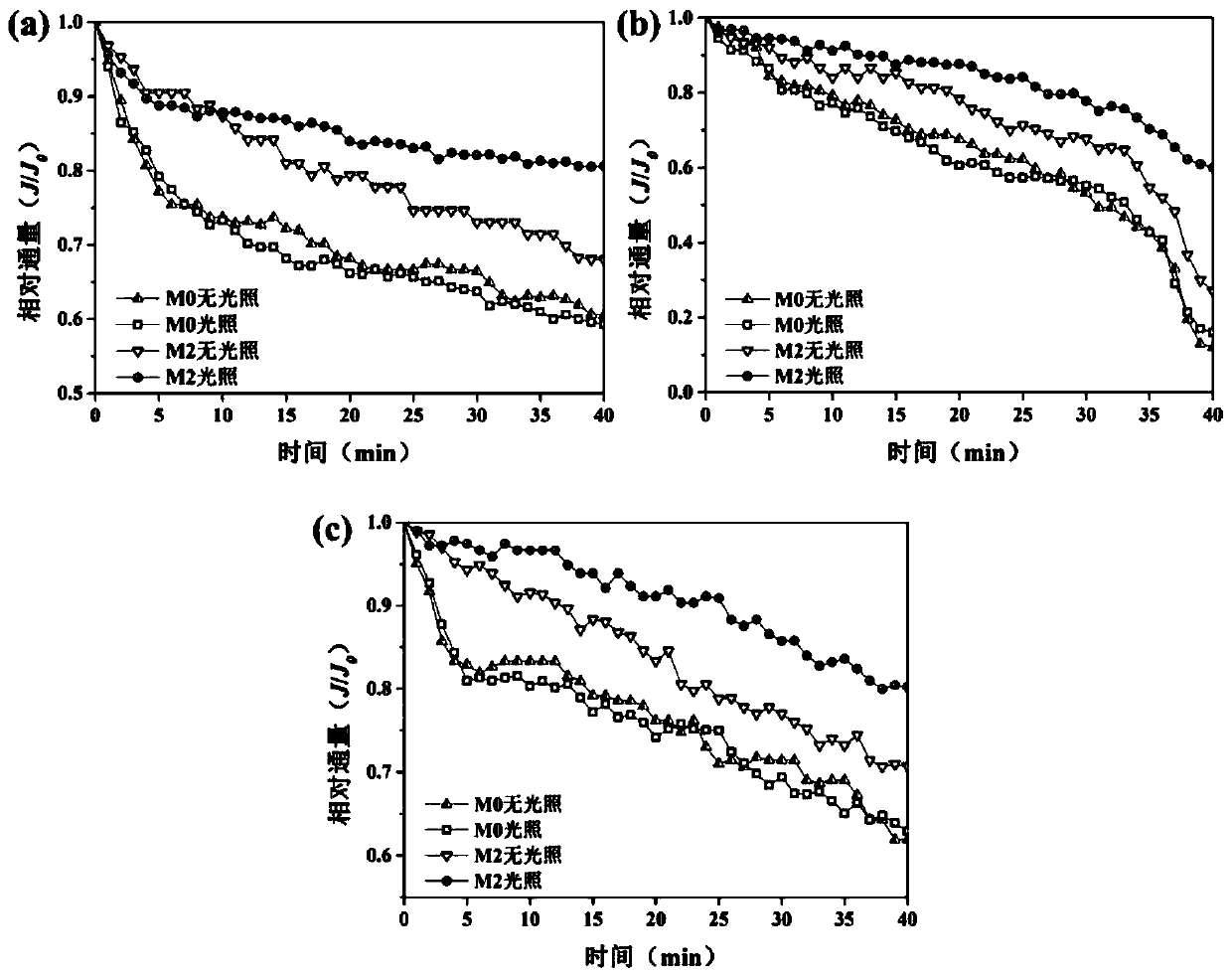

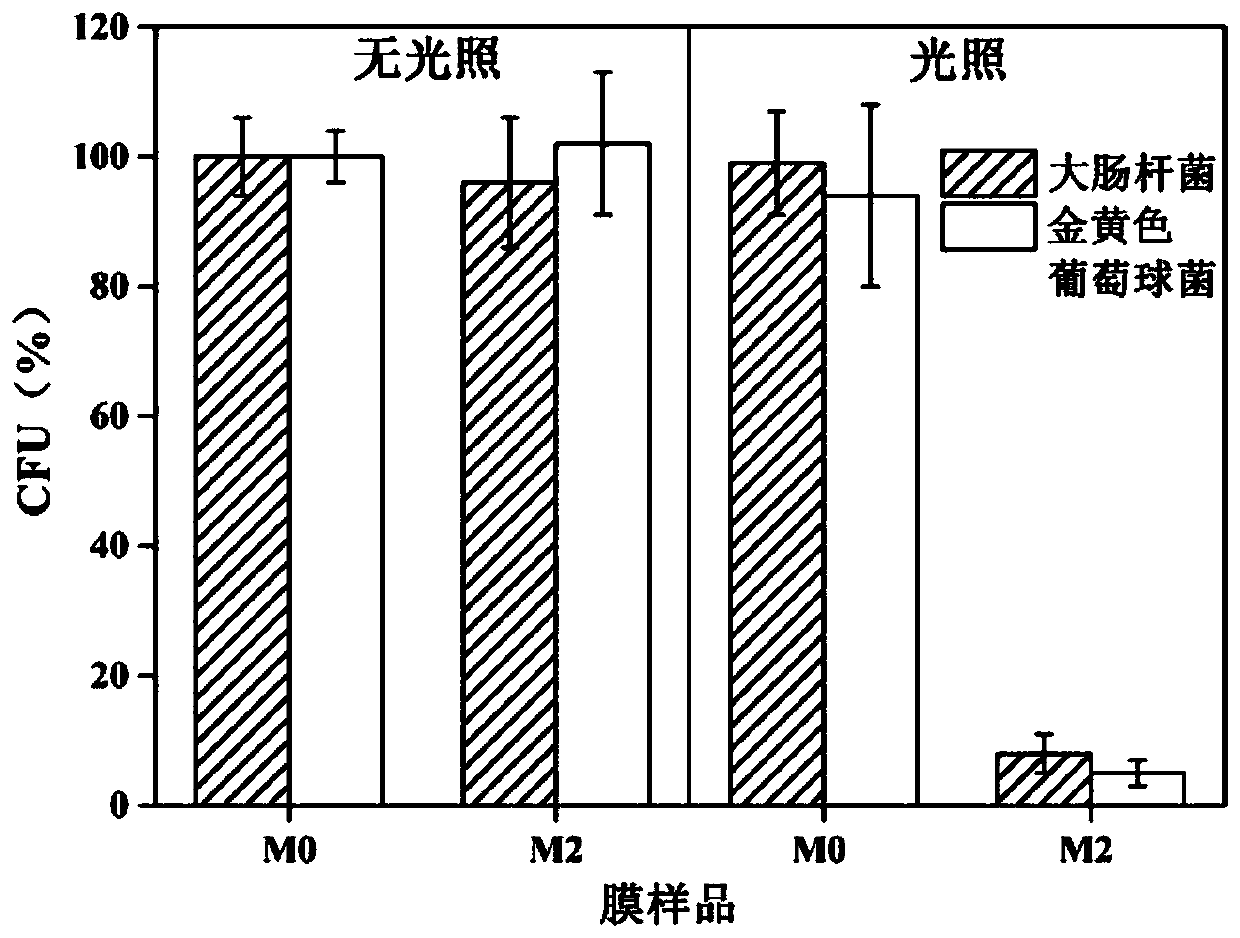

Examples

Embodiment 1

[0045] (1) CdS / g-C 3 N 4 Preparation of / rGO nanophotocatalyst

[0046] Firstly, a sufficient amount of cadmium sulfide (CdS), graphitic carbon nitride (g-C 3 N 4 ) and graphene oxide (GO), weigh 100mg g-C 3 N 4 Disperse in 30 mL of methanol by ultrasonication for 60 min, add 1 g of CdS, stir and mix for 20 h, remove the remaining methanol with a rotary evaporator, and dry the product at 50°C to obtain CdS / g-C 3 N 4 ; Weigh 50mg GO ultrasonically for 20min and disperse in the mixed solution of 100mL ethanol and water, wherein the volume ratio of ethanol to water is 1:3, then add the above CdS / g-C 3 N 4 , sonicate for 20 minutes and stir for 40 minutes, and centrifuge at 7000 rpm; redisperse the obtained precipitate in 80 mL of deionized water, adjust the pH of the solution to 8.5 with ammonia water, add 0.5 mL of hydrazine hydrate with a concentration of 30% and transfer it to an autoclave Hydrothermal reaction at 80°C for 2h, natural cooling and washing with deionized...

Embodiment 2

[0055] (1) CdS / g-C 3 N 4 Preparation of / rGO nanophotocatalyst

[0056] First prepare sufficient amount of CdS, g-C 3 N 4 and GO, weighed 100mg g-C 3 N 4 Disperse in 40mL methanol by ultrasonication for 70min, add 1.5g CdS, stir and mix for 24h, remove the remaining methanol with a rotary evaporator, and dry the product at 60°C to obtain CdS / g-C 3 N 4 ; Weigh 75 mg GO and ultrasonically disperse it in 120 mL of ethanol and water mixed solution for 25 min, wherein the volume ratio of ethanol to water is 1:3, and then add the above CdS / g-C 3 N 4 , sonicate for 25 minutes and stir for 50 minutes, and centrifuge at 7500 rpm; redisperse the obtained precipitate in 90 mL of deionized water, adjust the pH of the solution to 9.0 with ammonia water, add 0.8 mL of hydrazine hydrate with a concentration of 30% and transfer it to an autoclave Hydrothermal reaction at 85°C for 2h, natural cooling and washing with deionized water for 3 times, the product was vacuum-dried at 60°C to ...

Embodiment 3

[0066] (1) CdS / g-C 3 N 4 Preparation of / rGO nanophotocatalyst

[0067] First prepare sufficient amount of CdS, g-C 3 N 4 and GO, weighed 100mg g-C 3 N 4 Disperse in 50mL of methanol by ultrasonication for 80min, add 2g of CdS, stir and mix for 30h, remove the remaining methanol with a rotary evaporator, and dry the product at 70°C to obtain CdS / g-C 3 N 4 ; Weigh 100mg GO and ultrasonically disperse it in 150mL of ethanol and water mixed solution for 30min, wherein the volume ratio of ethanol to water is 1:3, and then add the above CdS / g-C 3 N 4 , ultrasonicated for 30min and stirred for 60min, centrifuged at 8000rpm; redispersed the obtained precipitate in 100mL deionized water, adjusted the pH of the solution to 9.5 with ammonia water, added 1mL of hydrazine hydrate with a concentration of 30% and transferred it to an autoclave. Hydrothermal reaction at 90°C for 2.5h, natural cooling and washing with deionized water for 3 times, the product was vacuum-dried at 70°C t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com