Carbon nanotube loaded CdSe-g-C3N4 photocatalytic material and preparation method thereof

A cdse-g-c3n4, photocatalytic material technology, applied in the field of photocatalytic degradation of organic pollutants, can solve the problems of narrow absorption band, low degree of electron separation, small specific surface area, etc., to enhance light absorption intensity and broaden light absorption Band, the effect of improving the degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In order to achieve the above object, the present invention provides the following technical solutions: a carbon nanotube loaded CdSe-g-C 3 N 4 The photocatalytic material and its preparation method include the following formula raw materials in parts by weight: 8-10 parts of cadmium chloride, 10-12 parts of sodium selenosulfate, 30-34 parts of urea, 28-32 parts of melamine, 12- 24 parts of carbon nanotubes, the preparation method includes and the following experimental drugs: distilled water, dilute hydrochloric acid, absolute ethanol, CdCl in cadmium chloride 2 Its mass fraction is ≥92.2%, Na in sodium selenosulfate 2 SeSO 3 Its mass fraction is ≥94.5%, and the structural formula of urea is , its mass fraction is ≥96.5%, and the structural formula of melamine is , its mass fraction ≥ 97.8%, carbon nanotubes are multi-walled carbon nanotubes, size specifications: length 30-50 um diameter 8-15nm, substance concentration of dilute hydrochloric acid 3.3-3.6 mol / L, m...

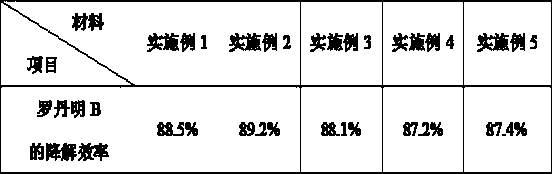

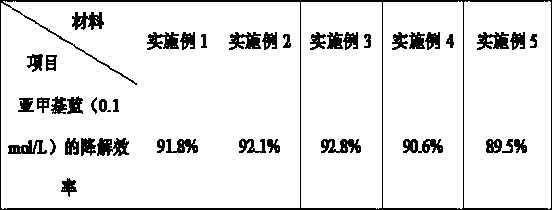

Embodiment 1

[0029] (1) Preparation of high-purity micron CdSe: Add 500 mL of distilled water to a 1000 mL beaker, then weigh 8 parts of cadmium chloride and 10 parts of sodium selenosulfate into the beaker, stir well, and transfer the materials in the beaker to into the high-pressure hydrothermal reactor, and the reactor was placed in the reactor heating box, heated to 130 ° C for 12 h, after the reaction was completed, the high-pressure hydrothermal reactor was cooled to room temperature, and then the materials in the reactor were filtered to remove the solvent. To obtain solid particles, use 300 mL of dilute hydrochloric acid with a substance concentration of 3.3 mol / L and 3000 mL of distilled water to wash the solid particles to remove reactants and side reaction products, and then place the washed CdSe solid particles in a high-energy planetary ball mill, Add 300 mL of ethanol, rotate at 200 rpm, and mill for 6 hours until all the CdSe materials pass through an 800-mesh sieve. Finally,...

Embodiment 2

[0033] (1) Preparation of high-purity micron CdSe: Add 500 mL of distilled water to a 1000 mL beaker, then weigh 8.5 parts of cadmium chloride and 10.5 parts of sodium selenosulfate into the beaker, stir well, and transfer the materials in the beaker to Put the reaction kettle into the high-pressure hydrothermal reaction kettle, place the reaction kettle in the heating box of the reaction kettle, heat it to 130 ° C for 18 h, and cool the high-pressure hydrothermal reaction kettle to room temperature after the reaction is complete, then filter the materials in the reaction kettle to remove the solvent, To obtain solid particles, use 300 mL of dilute hydrochloric acid with a concentration of 3.3 mol / L and 4000 mL of distilled water to wash the solid particles to remove reactants and side reaction products, and then place the washed CdSe solid particles in a high-energy planetary ball mill, Add 300 mL of ethanol, rotate at 200 rpm, and mill for 8 h until the CdSe material passes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com