A bismuth vanadate electrode rich in surface oxygen vacancies and its preparation method and application

A bismuth vanadate and oxygen vacancy technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve the problems of poor charge transport carrier separation ability, bismuth vanadate gap, and difficult to control the bulk oxygen vacancy content, and achieve The effect of avoiding bulk defect sites, low cost, high photoelectric conversion efficiency and photocurrent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of precursor solution: Weigh 0.2425g of bismuth nitrate and 0.1325g of vanadium oxide acetylacetonate, and dissolve them in 500 μL of dimethyl sulfoxide to obtain a 1mol / L precursor solution;

[0038] (2) Take 75 μL of the above precursor solution and drop-coat it on a 2×2 cm preheated to 60°C 2 On the FTO conductive glass;

[0039] (3) The precursor solution is uniformly coated on the FTO by a spin coater according to certain spin coating parameters. The spin coating parameters are 1000rpm for 20s, 4000rpm for 40s, and an acceleration of 1000rpm / s;

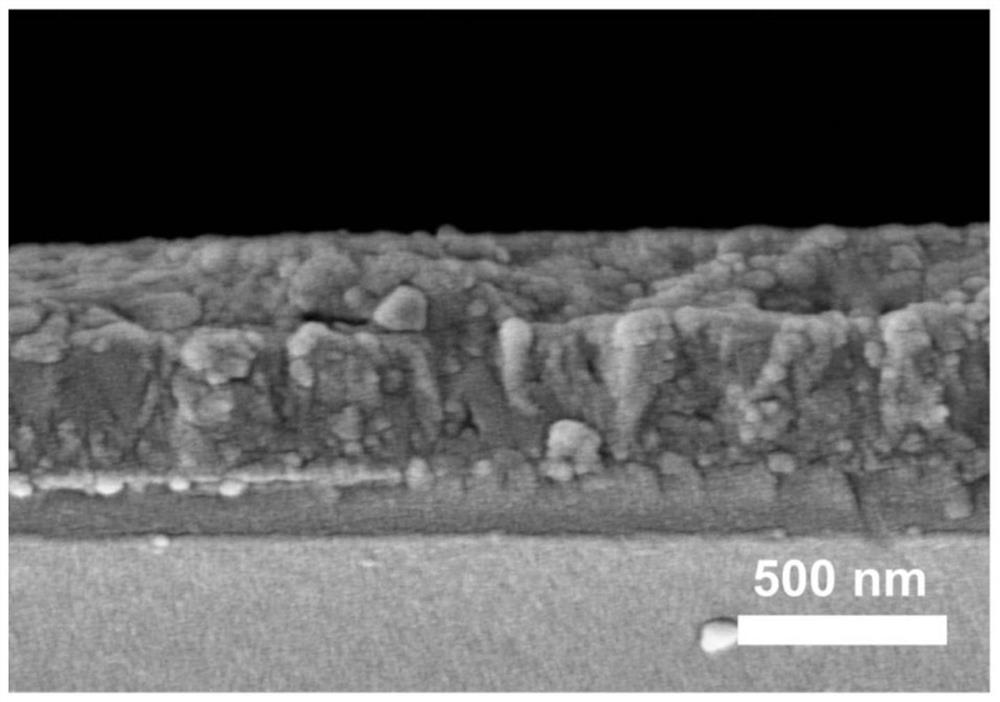

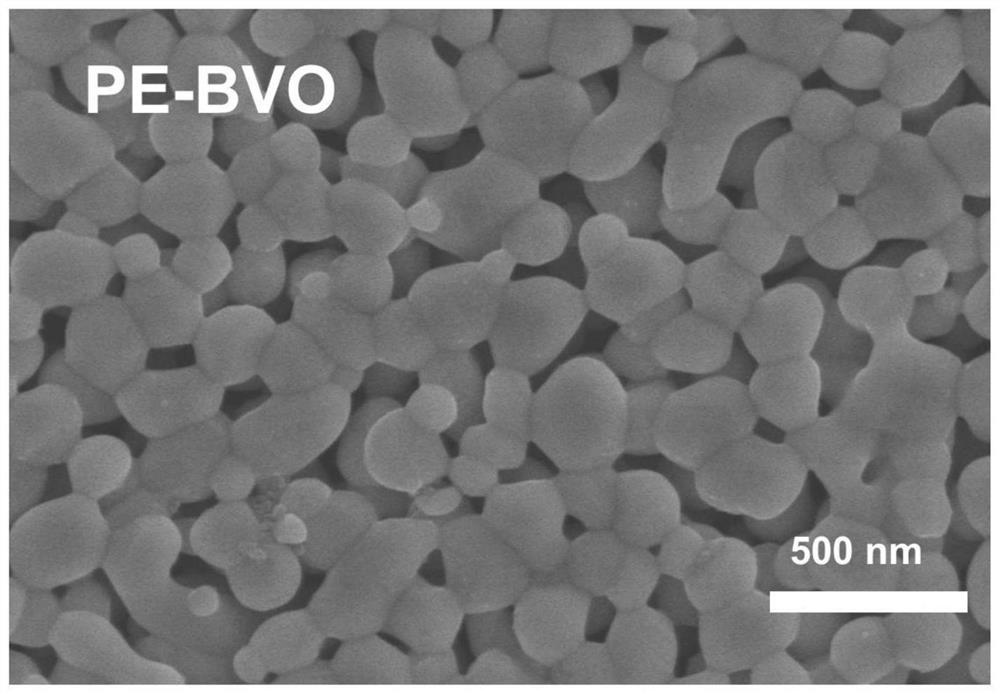

[0040] (4) Place the above sample in a tube furnace with an air atmosphere for sintering, the sintering system is 450-500°C for 2h, the heating rate is 5°C / min, and then cooled to room temperature to obtain a bismuth vanadate thin film electrode (denoted as BVO );

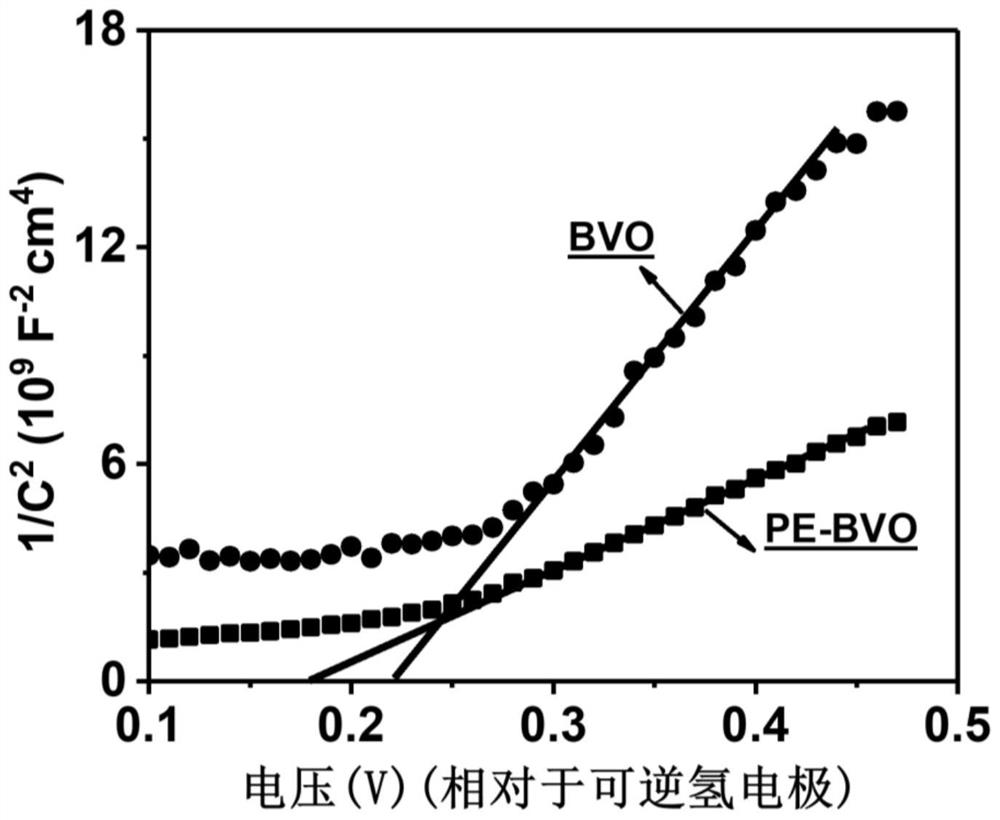

[0041] (5) The above-mentioned bismuth vanadate thin film electrode is immersed in the potassium borate solution of 1mol / L that the pH that c...

Embodiment 2

[0044] Adopt the method for embodiment 1 to react, and its difference is only, does not comprise step (5).

Embodiment 3

[0046] Adopt the method for embodiment 1 to carry out reaction, and its difference is only, the substrate in the step (2) is ITO conductive glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com