Preparation method of soluble hemostatic textile material

A technology for textile materials and production methods, applied in textiles and papermaking, rayon manufacturing, biochemical fiber treatment, etc., can solve the problems of aggravating the pain of patients, environmental pollution of waste gauze, adverse wound growth, etc., and achieves improved solubility, improved hand feel, The effect of excellent antibacterial and deodorizing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

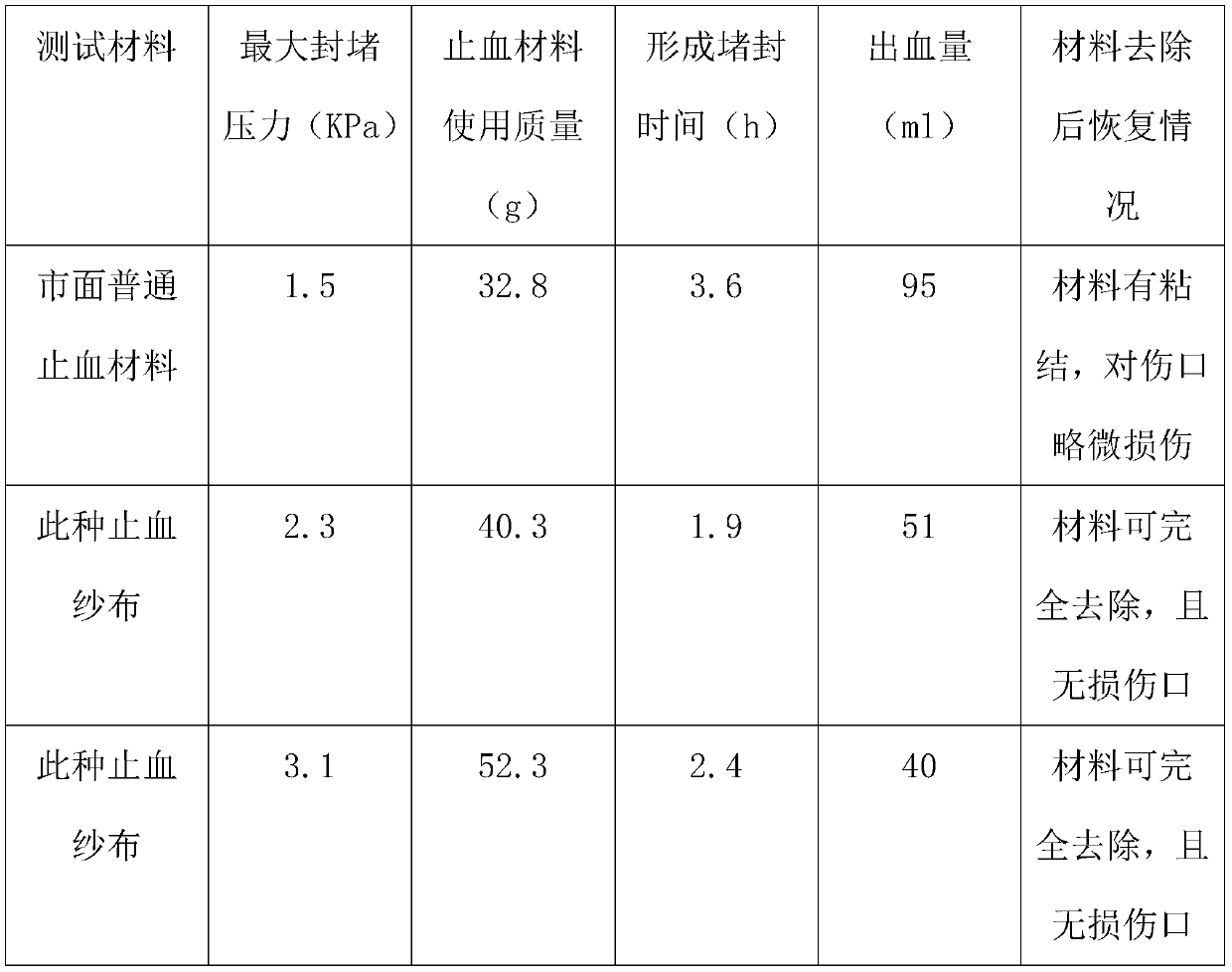

Examples

Embodiment 1

[0027] A method for making a soluble hemostatic textile material, the raw materials for the preparation of the soluble hemostatic textile material are:

[0028] (1) Raw material parts by weight of raw material for spinning: 100 parts of polyethylene terephthalate; 20-30 parts of polyacrylonitrile; 80-100 parts of organic solvent; 10-15 parts of antistatic agent; 5-10 parts of agent; 20-30 parts of polyvinyl alcohol; 60-75% ethanol solution containing 3mol / L sodium hydroxide.

[0029] (2) Raw material parts by weight of antibacterial liquid: 6-10 parts of glucose; 3-5 parts of yeast extract; 10-15 parts of agar; 3-5 parts of peptone; 4 parts of citric acid; 2 parts of zinc nitrate solution; silver nitrate 2 parts of solution; 30-40 parts of 3% trisodium citrate solution.

[0030] (3) The raw materials required for the preparation of hemostatic textile materials are: 4mol / L chloroacetic acid reaction liquid; hydrochloric acid solution; deionized water.

[0031] The specific st...

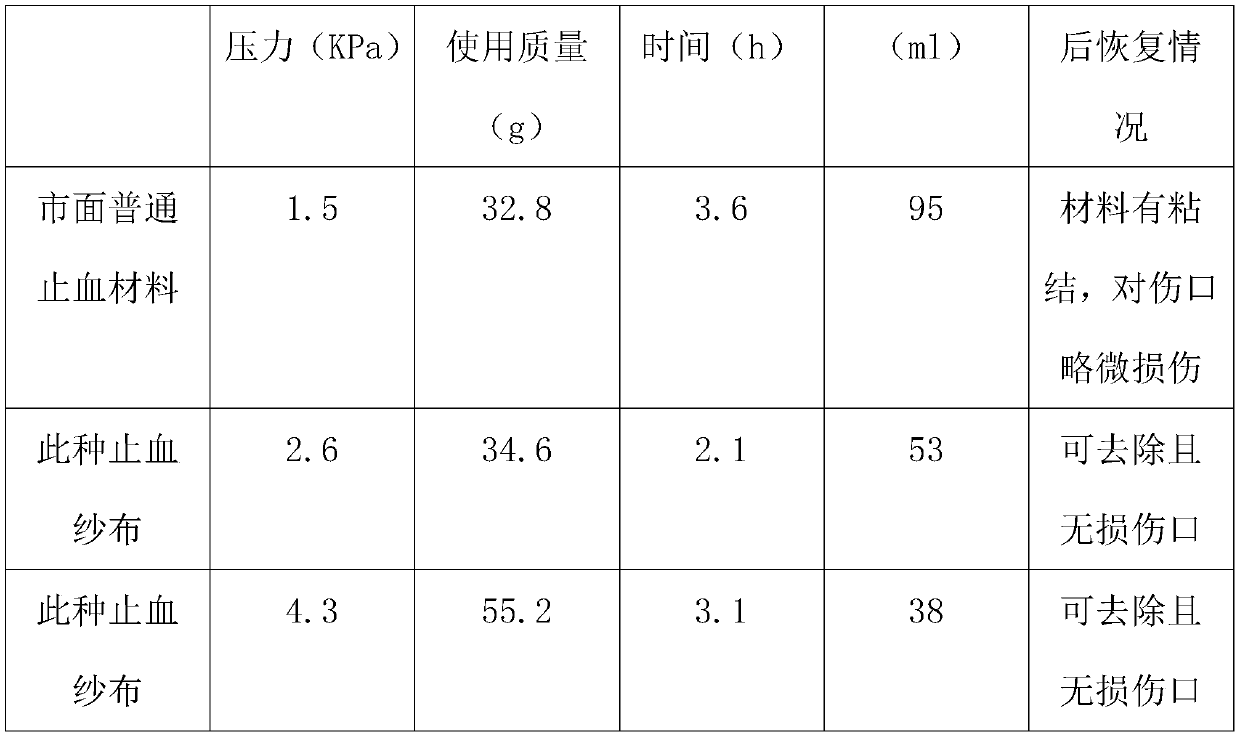

Embodiment 2

[0042] A method for making a soluble hemostatic textile material, the raw materials for the preparation of the soluble hemostatic textile material are:

[0043] (1) Raw material parts by weight of raw material for spinning: 100 parts of polyethylene terephthalate; 20-30 parts of polyacrylonitrile; 80-100 parts of organic solvent; 10-15 parts of antistatic agent; 5-10 parts of agent; 20-30 parts of polyvinyl alcohol; 60-75% ethanol solution containing 3mol / L sodium hydroxide.

[0044] (2) Raw material parts by weight of antibacterial liquid: 6-10 parts of glucose; 3-5 parts of yeast extract; 10-15 parts of agar; 3-5 parts of peptone; 4 parts of citric acid; 2 parts of zinc nitrate solution; silver nitrate 2 parts of solution; 30-40 parts of 3% trisodium citrate solution.

[0045] (3) The raw materials required for the preparation of hemostatic textile materials are: 4mol / L chloroacetic acid reaction liquid; hydrochloric acid solution; deionized water.

[0046] The specific st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com