Carbon-silicon carbide porous filter for purifying air and preparation method thereof

A porous filter and air purification technology, which is applied in the direction of chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of inability to filter fine particles, poor dust filtration effect, and low filtration efficiency, so as to improve the level of filtration accuracy, Small air resistance, promotes the effect of complete removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

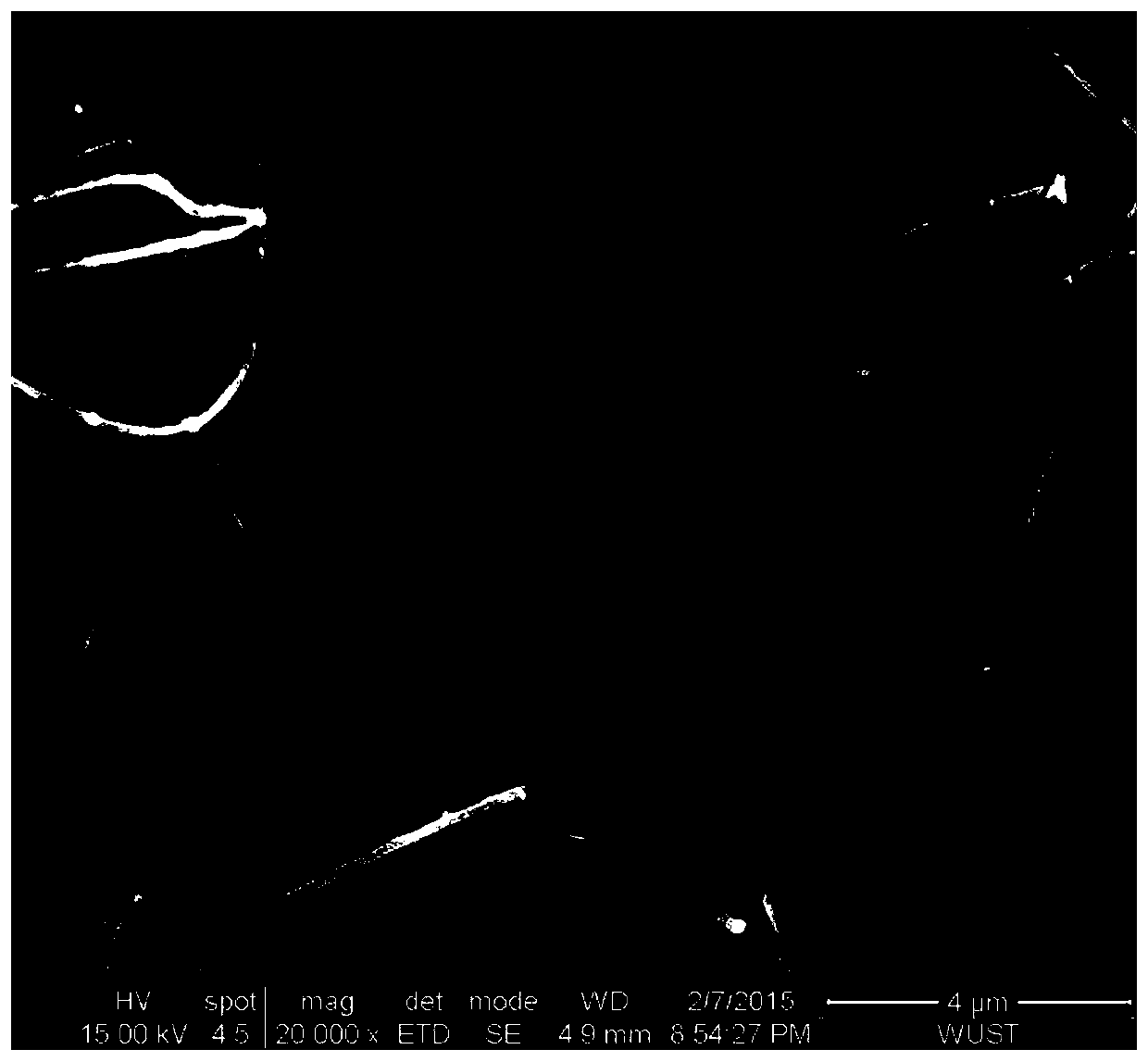

Image

Examples

preparation example Construction

[0028] The preparation method of the activated carbon is: under the condition of 600-800 DEG C and an inert atmosphere, the microcrystalline graphite is subjected to microwave treatment for 1-5 minutes to obtain the activated carbon; the average particle diameter of the activated carbon is ≤5 μm.

[0029] The average particle size of the elemental silicon is ≤15 μm; the Si content of the elemental silicon is ≥98wt%.

[0030] The average particle size of the microsilica powder is ≤0.5 μm; the SiO of the microsilica powder 2 Content ≥ 97wt%.

[0031] The open porosity of the polyurethane sponge is more than or equal to 98%.

Embodiment 1

[0033] A carbon-silicon carbide porous filter for air purification and a preparation method thereof. The steps of the preparation method are:

[0034] Step 1: Take 60-65wt% coconut shell charcoal powder, 12-15wt% activated carbon powder, 10-18wt% elemental silicon and 6-8wt% silicon micropowder as raw materials, mix evenly to obtain the mixture; Add 3-5wt% ferric chloride powder, 0.3-0.6wt% carboxymethyl cellulose and 30-35wt% water to the mixture, and stir for 45-60 minutes to obtain a slurry.

[0035] Step 2. Immerse the polyurethane sponge in the slurry for 5-10 minutes, extrude it with counter-rollers, dry it at room temperature, and dry it at 90-110°C for 24-48 hours to obtain a carbon-silicon carbide porous filter blank body.

[0036] Step 3. Place the carbon-silicon carbide porous filter body in an atmosphere sintering furnace. In the carbon-burying atmosphere: firstly raise the temperature to 200-220°C at a rate of 0.5-2°C / min, and then heat up to 200-220°C at a rate...

Embodiment 2

[0040] A carbon-silicon carbide porous filter for air purification and a preparation method thereof. The steps of the preparation method are:

[0041] Step 1. Take 65-70wt% coconut shell charcoal powder, 10-13wt% activated carbon powder, 17-25wt% elemental silicon and 5-7wt% silicon micropowder as raw materials, and mix them evenly to obtain the mixture; Add 1-3wt% ferric chloride powder, 0.1-0.3wt% carboxymethyl cellulose and 20-25wt% water to the mixture, and stir for 45-60 minutes to obtain a slurry.

[0042] Step 2. Immerse the polyurethane sponge in the slurry for 5-10 minutes, extrude it with counter-rollers, dry it at room temperature, and dry it at 90-110°C for 24-48 hours to obtain a carbon-silicon carbide porous filter blank body.

[0043] Step 3. Place the carbon-silicon carbide porous filter body in an atmosphere sintering furnace. In the carbon-burying atmosphere: firstly raise the temperature to 200-220°C at a rate of 0.5-2°C / min, and then heat up to 200-220°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com