Three-dimensional graphene-based nano zero-valent iron material as well as preparation method and application thereof

A nano-zero-valent iron, graphene-based technology, applied in chemical instruments and methods, catalyst activation/preparation, water/sludge/sewage treatment, etc., can solve the application of three-dimensional graphene/iron-based composite materials. The application of graphene/zero-valent iron composite materials, etc., to achieve the effect of improving the transfer effect of electrons, strong stability and strong magnetism, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Weigh 2g graphite powder and 1g NaNO 3 To mix, add 46 mL concentrated H 2 SO 4 Place in an ice bath and add 6 g of KMnO with rapid stirring 4 , to obtain mixture C. KMnO 4 It must be added slowly to the reaction solution to prevent the temperature of the reaction system from increasing sharply, and the temperature of the reaction solution should be controlled below 20°C. After reacting for 2 h, the mixture C was transferred to a warm water bath at 35° C. to continue the reaction for 40 min. After the reaction, add 92mL deionized water while stirring, control the temperature of the reaction solution at about 98°C, continue stirring for 30min, add 440mL deionized water to dilute, and slowly add a certain amount of H 2 o 2 Carry out high-temperature reaction, at this time the reaction solution turns golden yellow (generally hydrogen peroxide 10-50mL), and mixture D is obtained. The two additions of deionized water must be added slowly, because unreacted concentrated...

Embodiment 2

[0062] Weigh 2g graphite powder and 1g NaNO 3 To mix, add 46 mL concentrated H 2 SO 4 Place in an ice bath and add 8 g of KMnO with rapid stirring 4 , to obtain mixture C. KMnO 4 It must be added slowly to the reaction solution to prevent the temperature of the reaction system from increasing sharply, and the temperature of the reaction solution should be controlled below 20°C. After reacting for 2 h, the mixture C was transferred to a warm water bath at 35° C. to continue the reaction for 45 min. After the reaction, add 100mL deionized water while stirring, control the temperature of the reaction solution at about 98°C, continue stirring for 35 minutes, add 500mL deionized water to dilute, and slowly add a certain amount of H 2 o 2 A high-temperature reaction was carried out, and the reaction solution turned golden yellow at this time, and a mixture D was obtained. The two additions of deionized water must be added slowly, because unreacted concentrated sulfuric acid w...

Embodiment 3

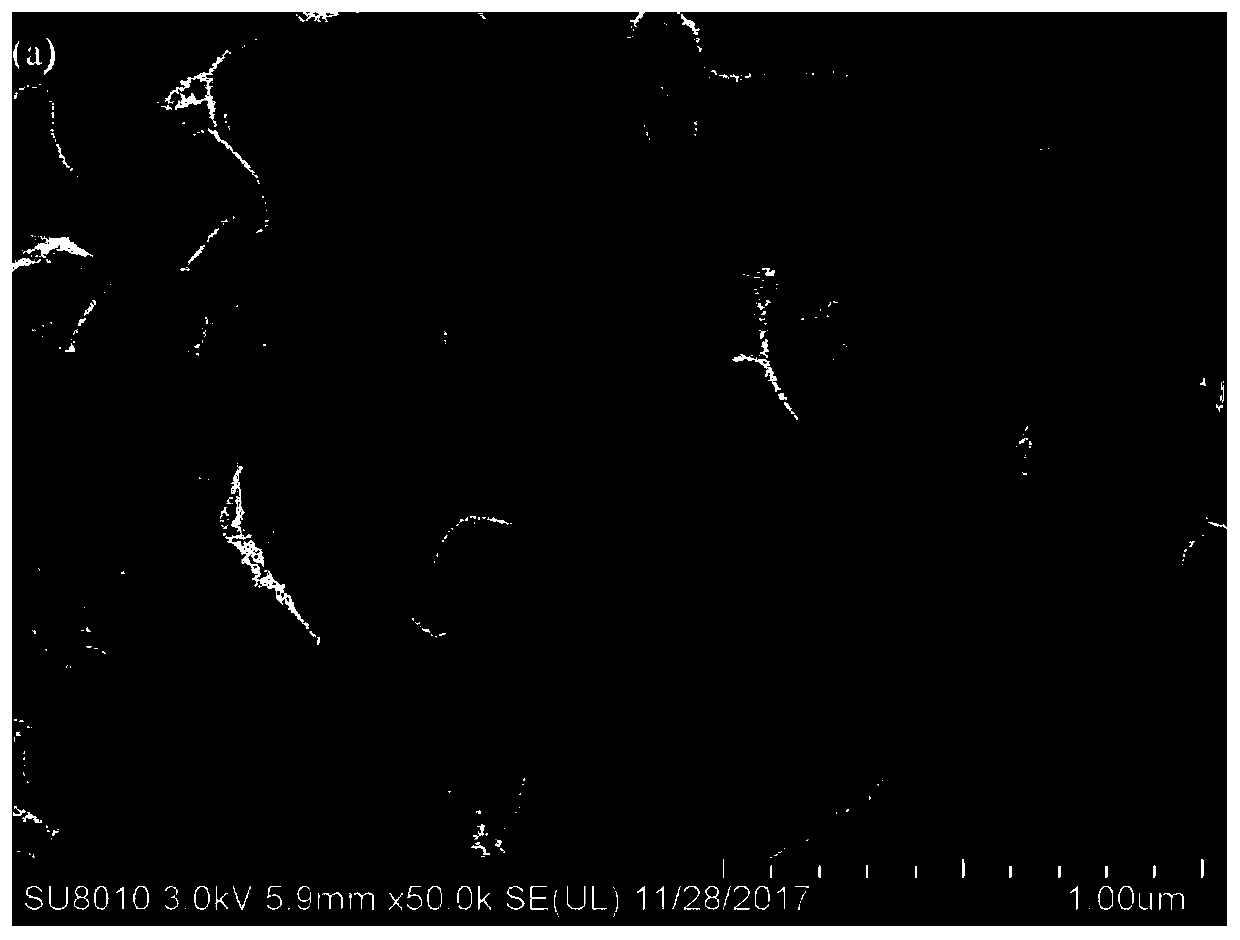

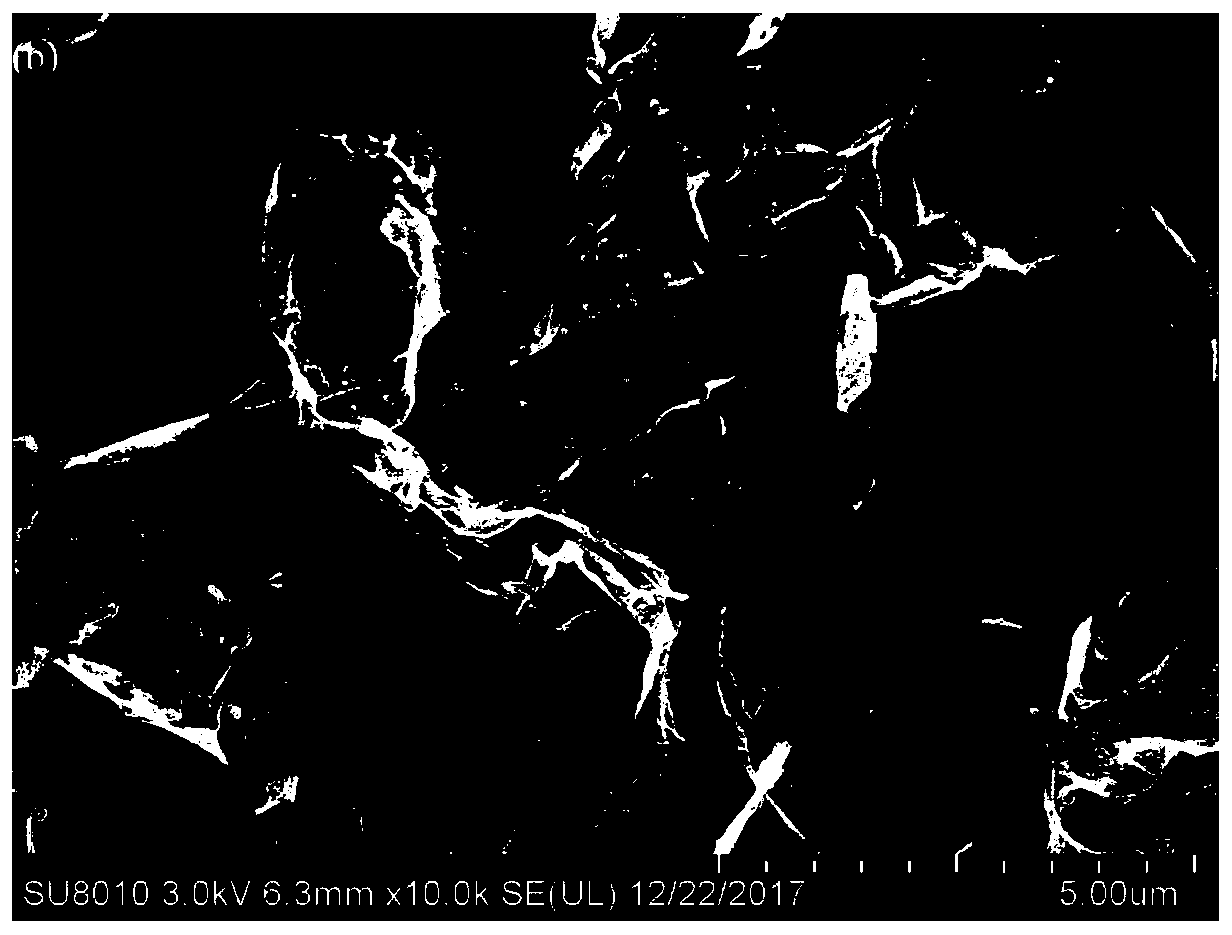

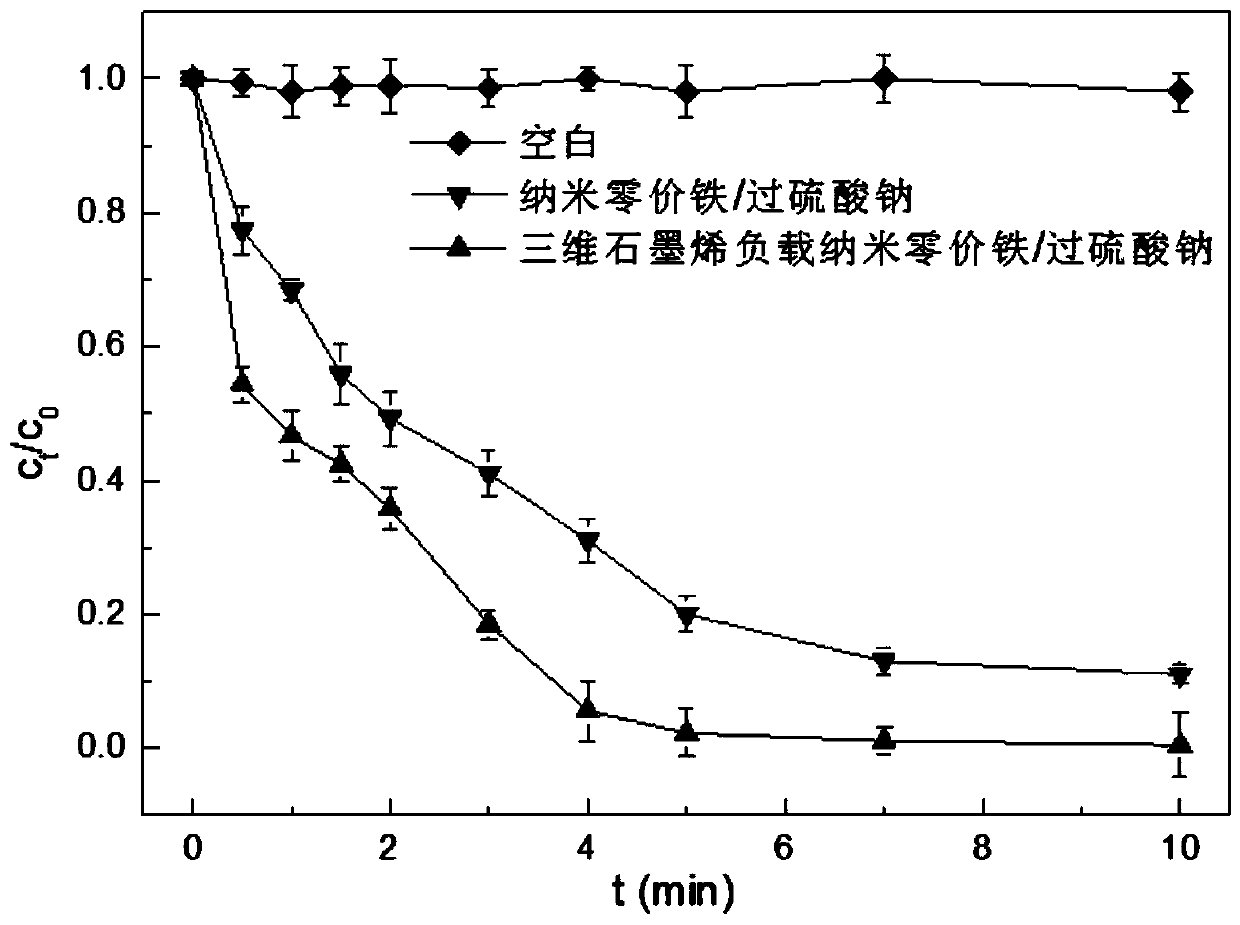

[0066] Add 6 mg of three-dimensional graphene-based nano-zero-valent iron material into a 40 mL EPA bottle (the mass ratio of three-dimensional graphene to iron element is 1:3, and the same mass of nano-zero-valent iron is used as a control), add an appropriate amount of distilled water, and then add 40 μL concentration For phorate of 10000ppm, finally add 62 μL of 800mM sodium persulfate solution to make the molar ratio of iron content in the three-dimensional graphene-based nano-zero-valent iron material to 1:1, and immediately put it in a shaker for reaction, and the oscillation frequency 150rpm / min, after the reaction started, 0.5mL samples were taken at 0, 0.5, 1, 1.5, 2, 3, 4, 5, 7, and 10min respectively in a 2mL centrifuge tube, and 1mL n-hexane was added immediately for extraction (shaking table for 30min). Then take 0.7mL and measure it by gas chromatography-mass spectrometry in the injection vial.

[0067] The experimental results are shown in Table 1 and image 3A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com