High-power flexible single-enzyme glucose fuel cell and preparation method thereof

A fuel cell and glucose technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems of low battery power density, low enzyme immobilization, weak electron transfer, etc., and achieve low cost, high sensitivity, and large open circuit voltage and the effect of power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 glucose fuel cell

[0032] The glucose fuel cell of this embodiment is prepared by the following method:

[0033] (1) Using graphite powder as raw material, graphene oxide (GO) was synthesized by the improved Hummers method: a 250mL three-necked flask was placed in an ice-water bath, and 35mL concentrated H 2 SO 4 , add 0.6g graphite powder and 1.0g NaNO while stirring 3 , continue stirring and add 3.0g KMnO 4 . Keep stirring at 35°C for more than 2h, add 150mL of distilled water to dilute, raise the temperature to 98°C, and stir for 5-15min. Preheat 200mL of deionized water (about 60°C) in advance, stir and slowly pour the reacted solution into it, then add 10mL of H 2 o 2 , the solution gradually turned yellow. Finally, filter while hot, wash and dry to obtain GO.

[0034] (2) Preparation of reduced graphene oxide (rGO) by chemical reduction method: at room temperature, 30 mg of brown GO, 27 mL of 1% trisodium citrate and 2 mL o...

Embodiment 2

[0039] With reference to the preparation steps of Example 1, the difference is that (3) in the preparation of the PTFE / rGO flexible electrode, the mass ratio of PTFE and rGO is adjusted, and the specific steps are as follows:

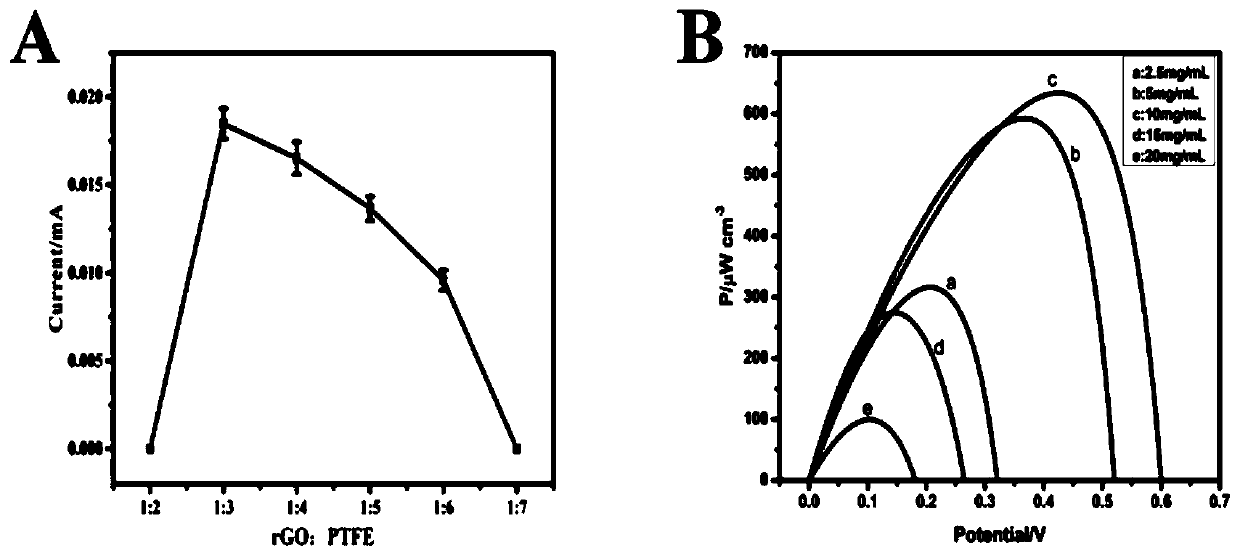

[0040] Weigh 4 parts of 0.04g rGO powder respectively, according to the mass ratio of rGO powder and PTFE 1:3, 1:4, 1:5, 1:6, mix rGO powder with 60% PTFE solution, press into tablets and dry. The rGO sheet after drying was used as the working electrode, the platinum electrode was used as the auxiliary electrode, and the saturated mercury glycoside electrode was used as the counter electrode to form a three-electrode system. Differential pulse voltammetry scanning was performed, and the results were as follows: image 3 As shown in A.

[0041] When the ratio of rGO and PTFE is 1:2 or 1:7, it is difficult to form a sheet when the two are mixed. As the amount of PTFE increases, the conductivity of rGO is suppressed, thereby reducing the electrochemical e...

Embodiment 3

[0043] Prepare bioanode according to Example 1, with different concentrations of Bi 3 Ti 2 o 8 F is mixed with 20mg / mL GOD solution in equal volume, and the power is measured and compared in the glucose solution. Specifically: mix 20mg / mL GOD solution with 2.5mg / mL, 5.0mg / mL, 10mg / mL, 20mg / mL Bi 3 Ti 2 o 8 The chitosan solution of F was mixed ultrasonically at a volume ratio of 1:1, the mixed liquid was dropped on the surface of the PTFE / rGO flexible electrode, and fixed with Nafion solution to prepare different bioanodes, and the power was measured in the glucose solution. The result is as image 3 As shown in B, when Bi 3 Ti 2 o 8 When F concentration is 5mg / mL, 10mg / mL, GOD: Bi 3 Ti 2 o 8 When the F mass ratio is 2:1 to 4:1, the open circuit voltage and power density are larger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com