Jerusalem artichoke meal inulin capable of improving functional dyspepsia and preparation method and application thereof

An indigestion, functional technology, applied in the application, digestive system, function of food ingredients, etc., can solve problems such as the treatment of functional indigestion with Jerusalem artichoke inulin, and achieve the goal of promoting industrial output value, lowering extraction temperature, and reducing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a method for preparing Jerusalem artichoke meal inulin for improving functional dyspepsia, comprising the following steps:

[0036] 1) mixing Jerusalem artichoke meal powder with a buffer solution containing glycosidase, enzymolysis and extraction to obtain an extract;

[0037] 2) removing protein and pectin macromolecular impurities from the extract by ultrafiltration to obtain a crude extract of Jerusalem artichoke meal inulin;

[0038] 3) Desalting and purifying the crude Jerusalem artichoke meal inulin extract to obtain a desalted Jerusalem artichoke meal inulin extract;

[0039] 4) The desalted Jerusalem artichoke meal inulin extract is subjected to secondary ultrafiltration to remove monosaccharide and oligosaccharide small molecule impurities, and dried to obtain Jerusalem artichoke meal inulin.

[0040] The invention mixes the jerusalem meal powder with the buffer solution containing glycosidase, extracts by enzymatic hydrolysis, ...

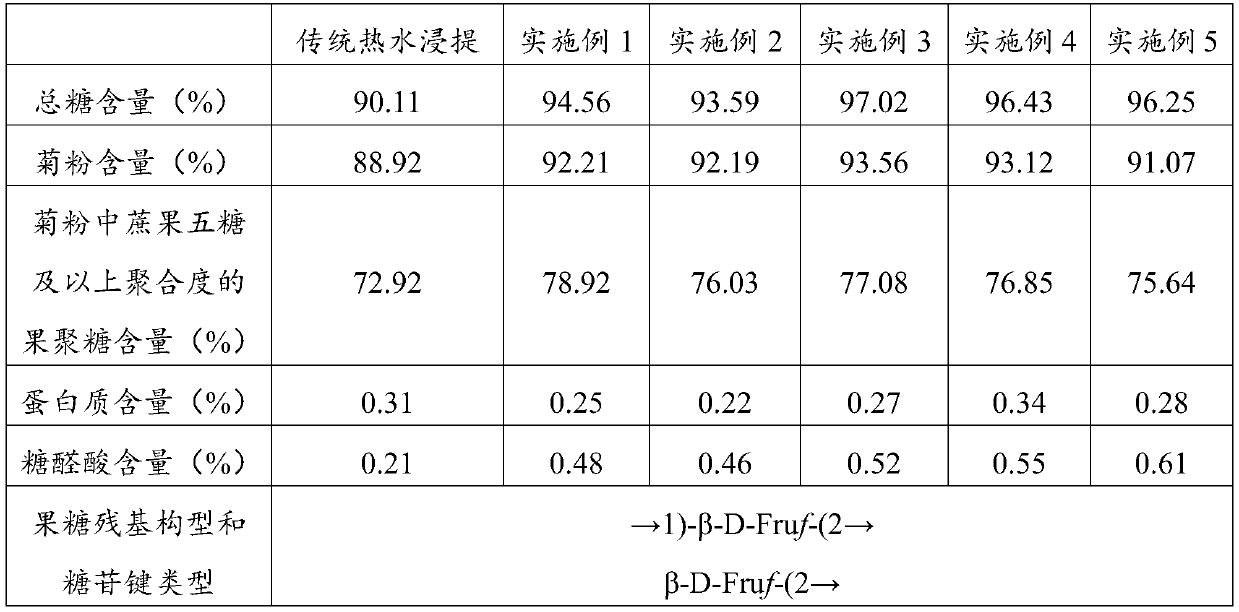

Embodiment 1

[0061] (1) The Jerusalem artichoke meal produced in the industrial production process of Jerusalem artichoke inulin is crushed by a food crusher (manufacturer: Chengxun Industrial Co., Ltd., model: CXP-DJ-S-5T);

[0062] (2) According to the material-to-liquid ratio of 1:10 (g / mL), add glucosidase (enzyme-to-substrate ratio is respectively pectinase 3U / g, cellulase 5U / g, hemicellulase 10U / g, xylem The ratio of carbohydrase is 5U / g) buffered saline solution (citric acid-sodium citrate buffer, 0.01mol / L, pH 4.0), extract at 45°C for 3h;

[0063] (3) The extract is removed by ultrafiltration to remove macromolecular impurities such as protein and pectin (membrane separation equipment: RNF-0460 type, ultrafiltration membrane molecular weight cut-off 20000Da, membrane area 0.2m 2 , Xiamen Fumei Technology Co., Ltd.; operating pressure difference 1.0Mpa, circulation flow rate 2L / min), to obtain the crude extract of Jerusalem artichoke meal inulin;

[0064] (4) The crude extract of ...

Embodiment 2

[0068] (1) The Jerusalem artichoke meal produced in the industrial production process of Jerusalem artichoke inulin is crushed by a food crusher (manufacturer: Chengxun Industrial Co., Ltd., model: CXP-DJ-S-5T);

[0069] (2) According to the material-to-liquid ratio of 1:30 (g / mL), add glucosidase (enzyme-to-substrate ratio is respectively pectinase 20U / g, cellulase 5U / g, hemicellulase 30U / g, xylem The ratio of carbohydrase is 20U / g) buffered saline solution (citric acid-sodium citrate buffer, 0.5mol / L, pH 5.5), extract at 55°C for 1h;

[0070] (3) The extract is removed by ultrafiltration to remove macromolecular impurities such as protein and pectin (membrane separation equipment: RNF-0460 type, ultrafiltration membrane molecular weight cut-off 20000Da, membrane area 0.2m 2 , Xiamen Fumei Technology Co., Ltd.; operating pressure difference 1.0Mpa, circulation flow rate 2L / min), to obtain the crude extract of Jerusalem artichoke meal inulin;

[0071] (4) The crude extract of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com