Polyether amine derivative modified styrene-acrylic emulsion and preparation method thereof

A technology of styrene-acrylic emulsion and polyether amine, which is applied in the direction of biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve the problems of insufficient crosslinking density, poor flexibility and hardness, etc., and achieve Good flexibility, good adhesion and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

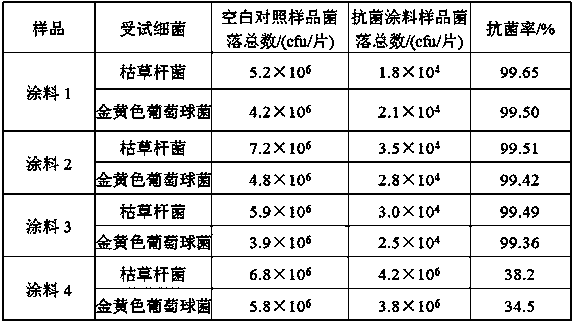

Image

Examples

Embodiment 1

[0031] A polyetheramine derivative modified styrene-acrylic emulsion, its components are: 10.0 parts of polyetheramine derivatives, 21.0 parts of methyl methacrylate, 5.0 parts of butyl methacrylate, 4.0 parts of methyl methacrylate in parts by weight. Isooctyl acrylate, 6.0 parts of glycidyl acrylate, 24.0 parts of styrene, 2.2 parts of hydroxypropyl acrylate, 3.0 parts of acrylic acid, 0.3 parts of benzoyl peroxide, 0.6 parts of sodium bicarbonate, 6.0 parts of triethylamine, 3.5 parts Parts of OP-10, 8.0 parts of diethylene glycol butyl ether, 160.0 parts of deionized water.

[0032] A kind of preparation method of polyether amine derivative modified styrene-acrylic emulsion in the present embodiment, comprises the following steps:

[0033] 1), in the storage tank, polyether amine derivatives, hydroxypropyl acrylate, benzoyl peroxide, acrylic acid, diethylene glycol butyl ether, glycidyl acrylate, methacrylic acid Stir methyl ester, butyl methacrylate, and isooctyl methacr...

Embodiment 2

[0037] A polyether amine derivative modified styrene-acrylic emulsion, its components are: 8.0 parts of polyether amine derivatives, 25.0 parts of isobornyl methacrylate, 10.0 parts of lauryl methacrylate, 5.0 parts by weight Parts glycidyl acrylate, 22.0 parts styrene, 2.5 parts hydroxyethyl methacrylate, 3.0 parts acrylic acid, 0.3 parts benzoyl peroxide, 0.5 parts sodium bicarbonate, 5.0 parts ammonia, 2.5 parts OP-10, 6.5 parts Propylene glycol methyl ether acetate, 150.0 parts of deionized water.

[0038] A kind of preparation method of polyether amine derivative modified styrene-acrylic emulsion in the present embodiment, comprises the following steps:

[0039] 1), in the storage tank, polyether amine derivatives, hydroxyethyl methacrylate, benzoyl peroxide, acrylic acid, propylene glycol methyl ether acetate, glycidyl acrylate, methacrylic acid Stir isobornyl ester and lauryl methacrylate evenly to obtain mixed solution Ⅰ;

[0040] 2) Add emulsifier, sodium bicarbonat...

Embodiment 3

[0043] A polyetheramine derivative modified styrene-acrylic emulsion, its components are: 7.0 parts of polyetheramine derivatives, 8.0 parts of acrylonitrile, 10.0 parts of methyl methacrylate, 4.0 parts of butyl methacrylate in parts by weight Esters, 3.5 parts of isooctyl methacrylate, 5.5 parts of glycidyl acrylate, 25.0 parts of styrene, 2.0 parts of hydroxybutyl acrylate, 3.0 parts of acrylic acid, 0.2 parts of benzoyl peroxide, 0.5 parts of sodium bicarbonate, 6.2 parts Triethylamine, 3.0 parts of OP-10, 6.5 parts of ethylene glycol monobutyl ether, 140.0 parts of deionized water.

[0044] A kind of preparation method of polyether amine derivative modified styrene-acrylic emulsion in the present embodiment, comprises the following steps:

[0045] 1), in the storage tank, polyether amine derivatives, hydroxybutyl acrylate, benzoyl peroxide, acrylic acid, ethylene glycol monobutyl ether, glycidyl acrylate, acrylonitrile, formaldehyde Methyl methacrylate, butyl methacrylat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com