Method for producing protein peptide through mixed enzymolysis of poultry feather and blood

A technology of mixed enzymatic hydrolysis and poultry feathers, which is applied in the field of protein peptide production, can solve the problems of lower digestibility and palatability, easy moisture absorption of products, imbalance of amino acids, etc., and achieve the goals of improving digestibility, difficulty in preservation, and improvement of moisture absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

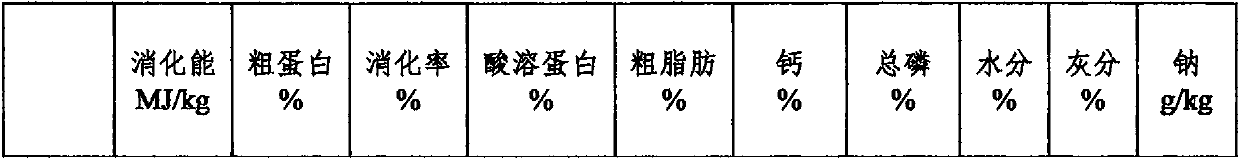

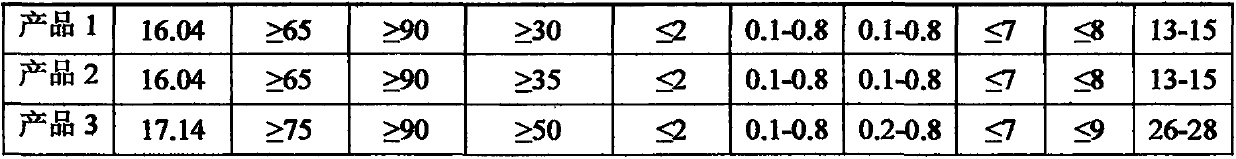

Embodiment 1

[0029] Example 1, a method for producing protein peptides by mixed enzymatic hydrolysis using poultry feathers and blood as raw materials, the obtained product is recorded as product 1, and the steps are:

[0030] (1) Put the fresh blood collected in the livestock slaughterhouse into cold storage tanks to keep fresh; wash and dehydrate the feathers collected in the slaughterhouse to be sterilized by autoclaving on the spot.

[0031] (2) Feathers are packed into the hydrolysis tank, add water, control the substrate concentration at 10% (W / W), add sodium pyrophosphite with 1% substrate mass, control the hydrolysis pressure to 0.3Mpa, and the hydrolysis temperature at 150°C , hydrolyzed for 80 minutes, open the pressure relief valve for pressure relief and exhaust, replenish water to maintain the substrate concentration of the feather hydrolyzate;

[0032] (3) Put fresh blood into a hydrolysis tank, add water, control the substrate concentration to 10% (W / W), add sodium pyrophosphi...

Embodiment 2

[0037] Example 2, a method for producing protein peptides by mixed enzymatic hydrolysis using poultry feathers and blood as raw materials, the obtained product is recorded as product 2, and the steps are:

[0038] (1) Put the fresh blood collected in the livestock slaughterhouse into cold storage tanks to keep fresh; wash and dehydrate the feathers collected in the slaughterhouse to be sterilized by autoclaving on the spot.

[0039] (2) Feathers are packed into the hydrolysis tank, add water, control the substrate concentration at 10% (W / W), add sodium pyrophosphite with 1% substrate mass, control the hydrolysis pressure to 0.3Mpa, and the hydrolysis temperature at 150°C , hydrolyzed for 80 minutes, open the pressure relief valve for pressure relief and exhaust, replenish water to maintain the substrate concentration of the feather hydrolyzate;

[0040] (3) Put fresh blood into a hydrolysis tank, add water, control the substrate concentration to 10% (W / W), add sodium pyrophosp...

Embodiment 3

[0045] Example 3, a method for producing protein peptides by mixed enzymolysis using poultry feathers and blood as raw materials, the obtained product is recorded as product 3, and the steps are:

[0046] (1) Put the fresh blood collected in the livestock slaughterhouse into cold storage tanks to keep fresh; wash and dehydrate the feathers collected in the slaughterhouse to be sterilized by autoclaving on the spot.

[0047] (2) Feathers are packed into the hydrolysis tank, add water, control the substrate concentration at 10% (W / W), add sodium pyrophosphite with 1% substrate mass, control the hydrolysis pressure to 0.3Mpa, and the hydrolysis temperature at 150°C , hydrolyzed for 80 minutes, open the pressure relief valve for pressure relief and exhaust, replenish water to maintain the substrate concentration of the feather hydrolyzate;

[0048] (3) Put fresh blood into a hydrolysis tank, add water, control the substrate concentration to 10% (W / W), add sodium pyrophosphite with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap