A spindle-shaped cus@ceo 2 Nanocomposite material and preparation method

A nanocomposite material and spindle technology, applied in the field of biomaterials, can solve the problems of ineffective treatment of deep tumors, lack of treatment of deep tumors, and large particle size of nanoparticles, and achieve intelligent response to the tumor microenvironment, high photothermal conversion efficiency, and increased The effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

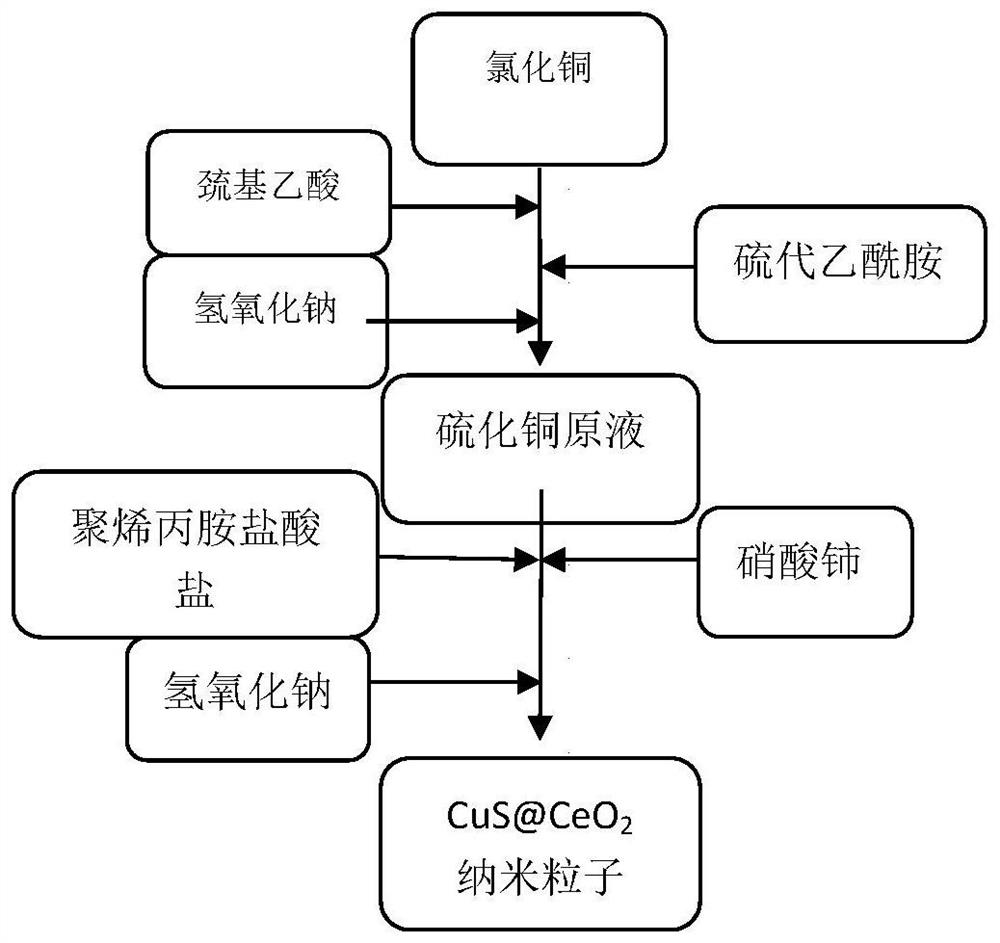

[0025] Spindle CuS@CeO 2 Preparation of nanocomposites (specific process such as figure 1 shown):

[0026] Weigh 17mgCuCl 2 ·H 2 O was added to 100mL deionized water, stirred in a 50°C water bath for 30min, then 14uL of mercaptoacetic acid was added, and the reaction was continued for 30min. The thioacetamide was added into the reaction system and reacted for 4 hours to obtain the copper sulfide reaction stock solution.

[0027] 500mgPAH and 217mgCe(NO 3 ) 3 ·6H 2 After O was added to the reaction system and stirred for 30 min, 0.5 mL NaOH (0.1 M) solution was prepared and poured into the reaction system. After reacting in a water bath at 50 °C for 12 hours, the spindle-shaped CuS@CeO was collected by centrifugation. 2 nanocomposites.

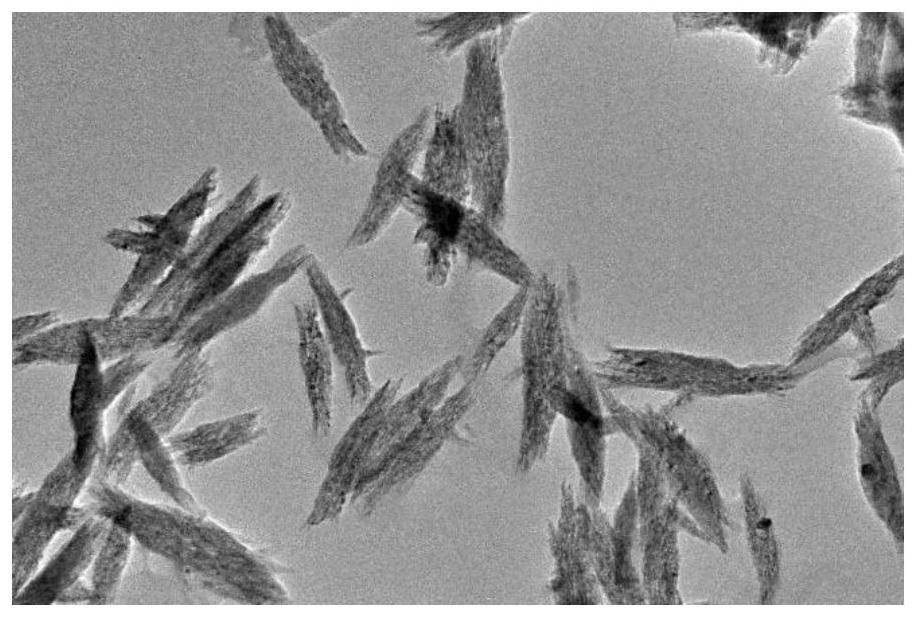

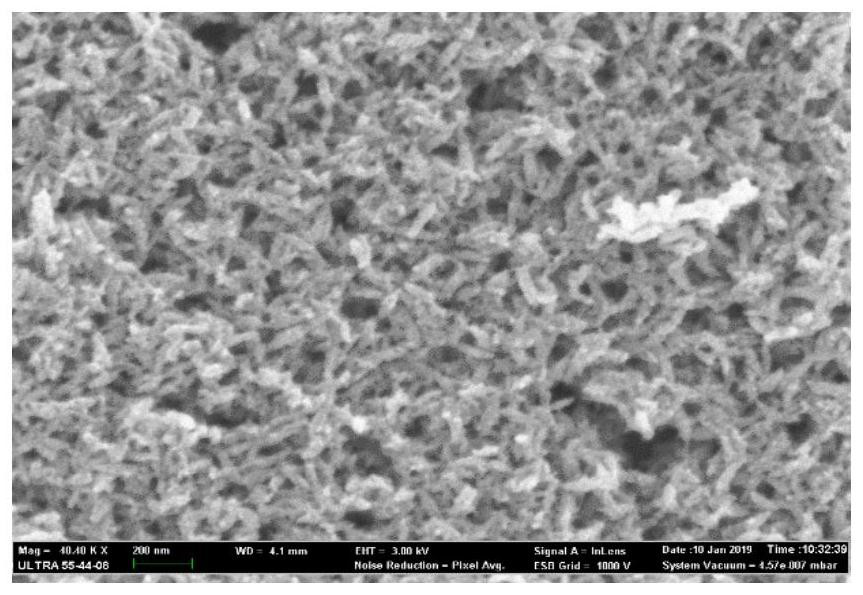

[0028] Spindle-shaped CuS@CeO prepared in the above examples 2 Nanocomposite materials through transmission electron microscopy figure 2 As shown, it can be clearly observed that the nanomaterials present a shuttle-shaped structure, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com