Method for separating and purifying fluorobenzene by extractive distillation

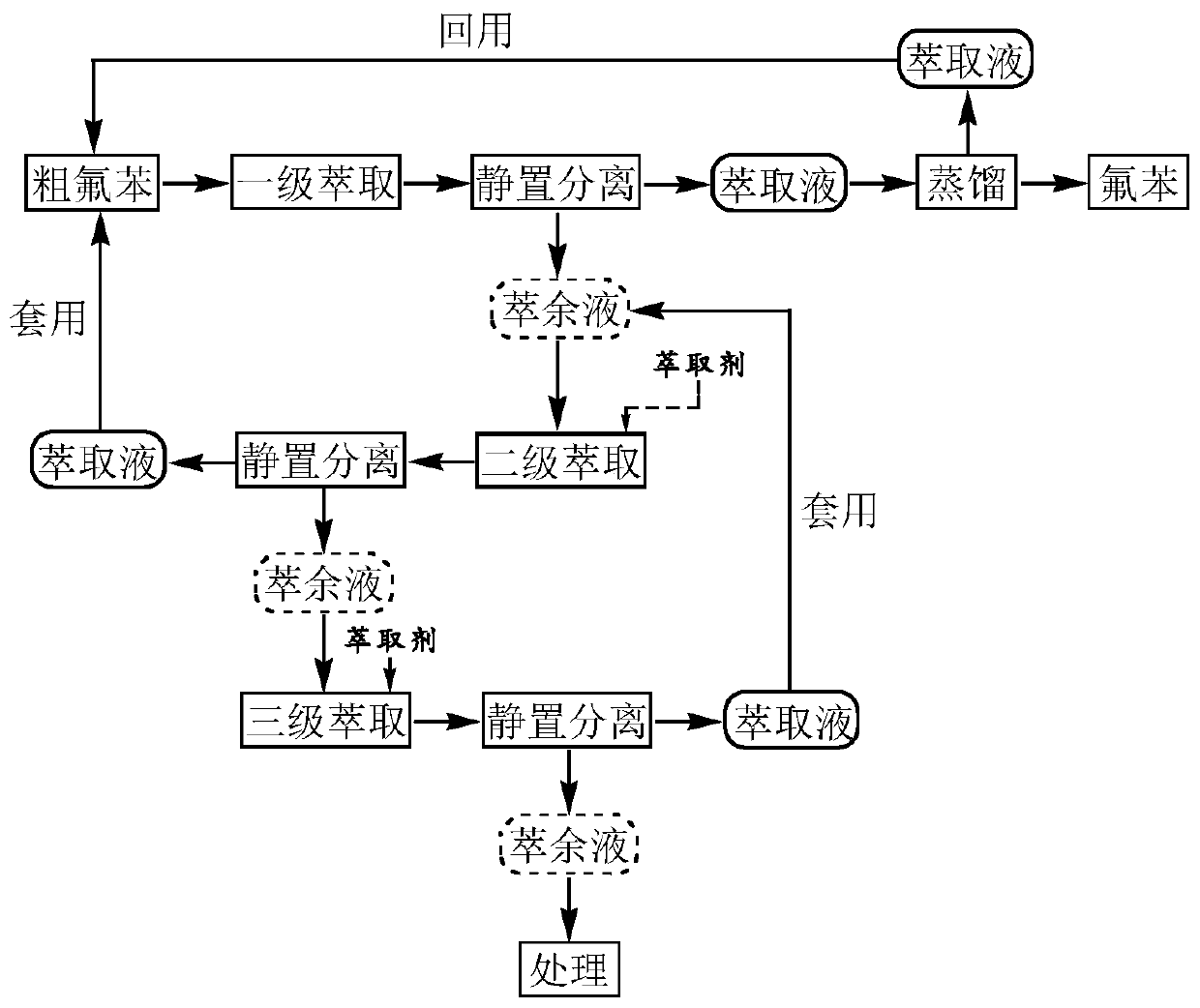

A separation, purification and extractive distillation technology is applied in the field of separation and purification of fluorobenzene in acidic fluorobenzene mixed solution, which can solve problems such as increasing consumption, and achieve the effects of reducing the amount of process wastewater and waste residue, improving product purity, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

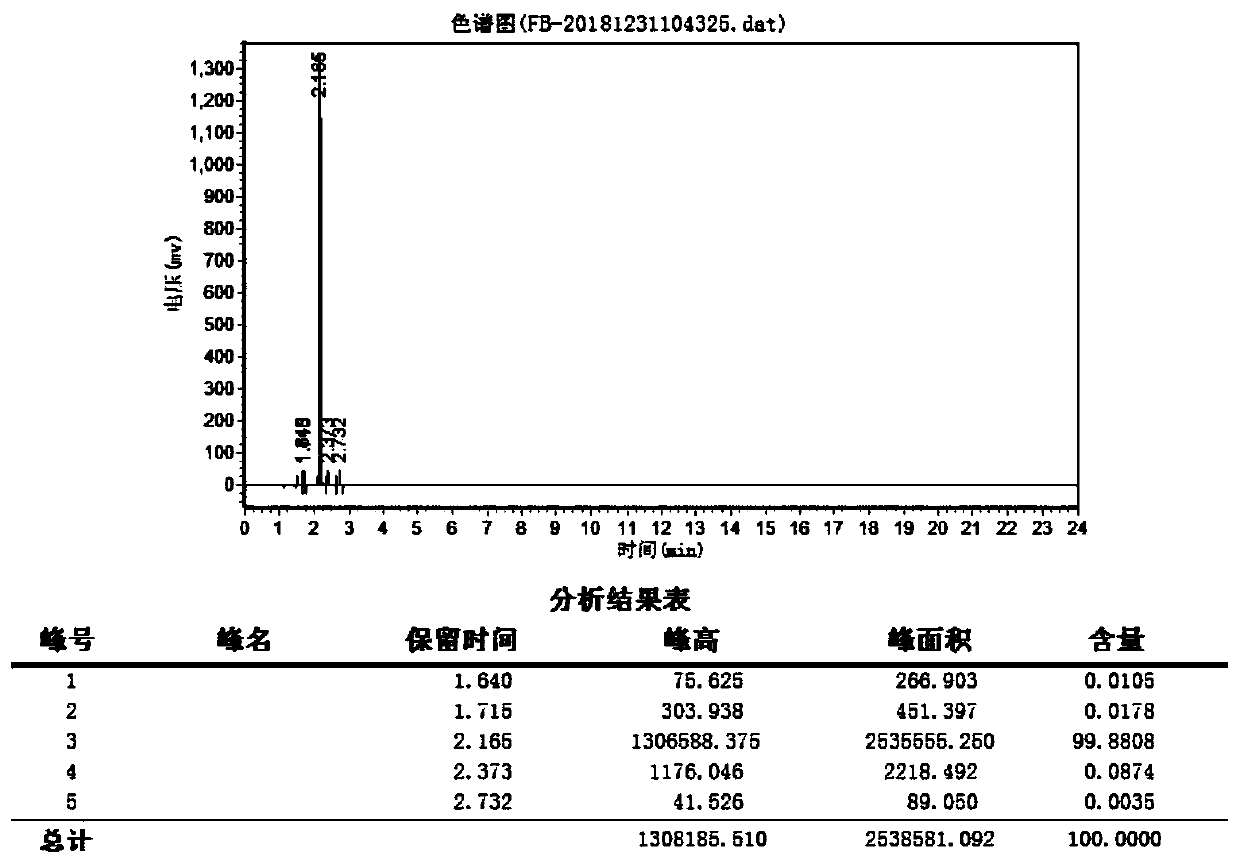

[0028] Add 150 mL of crude fluorobenzene organic phase mixture and 75 mL of dichloromethane ( That is, the ratio is 2.0), at 25 ° C, continuous stirring for 30 minutes. After standing still for 30 minutes, move the extract from the lower layer into a Webster fractionation column (height 60 cm, number of layers: 8), a condenser and a thermometer with an outer asbestos jacket, and adjust the temperature of the condenser and the thermal bath to control Reflux ratio to 1.2~1.4, carry out fractional distillation under normal pressure, and collect fractions at 40~42°C. When the reading of the thermometer in the fractionating column drops rapidly, continue to collect the distillate for about 2 to 5 minutes to obtain the dichloromethane recovery liquid. Continue to increase the temperature of the heating bath to 85°C. When it is detected that the content of fluorobenzene in the distillate gradually increases and the purity is higher than 99.5%, and the gas phase temperature rises ste...

Embodiment 2

[0031] The difference between this example and Example 1 is that the extraction ratio is 1.5, that is, take 150 mL of the crude fluorobenzene organic phase mixture, and 100 mL of dichloromethane, and keep the operating parameters of other processes unchanged, and collect dichloromethane and fluorine respectively. Benzene fraction.

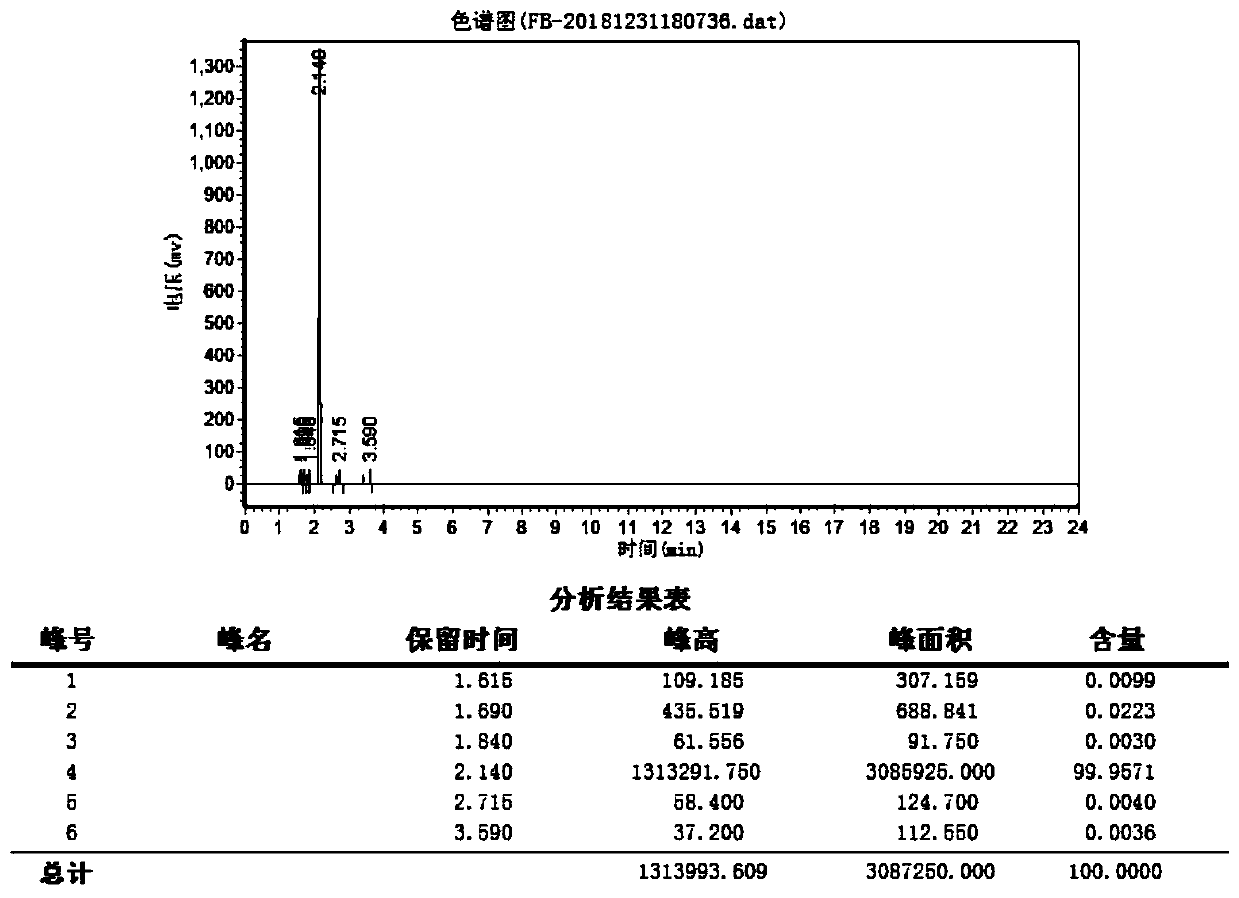

[0032] The extraction yield of fluorobenzene is about 95%, the total yield is about 94%, the purity reaches 99.96%, the residual amount of extractant is 40ppm; the recovery rate of extractant is about 95%. The gas chromatography analysis result of gained fluorobenzene product is as follows image 3 shown.

Embodiment 3

[0034] The difference between this embodiment and Example 1 is that the ratio during extraction is 1.0, that is, 150 mL of crude fluorobenzene organic phase mixed solution and 150 mL of dichloromethane are taken, and the operating parameters of other processes are unchanged, and dichloromethane and dichloromethane are collected respectively. Fluorobenzene fraction.

[0035]The extraction yield of fluorobenzene is about 96%, the total yield is about 95%, the purity reaches 99.95%, the residual amount of extractant is 54ppm; the recovery rate of extractant is about 95%. The gas chromatography analysis result of gained fluorobenzene product is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com