Construction and application of Escherichia coli engineering bacterium for immobilizing CO2 and producing malic acid

A technology of Escherichia coli and malic acid, applied in bacteria, microorganism-based methods, DNA/RNA fragments, etc., can solve the problems of inability to fix and the third level is not fully realized, and achieve the effect of alleviating the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

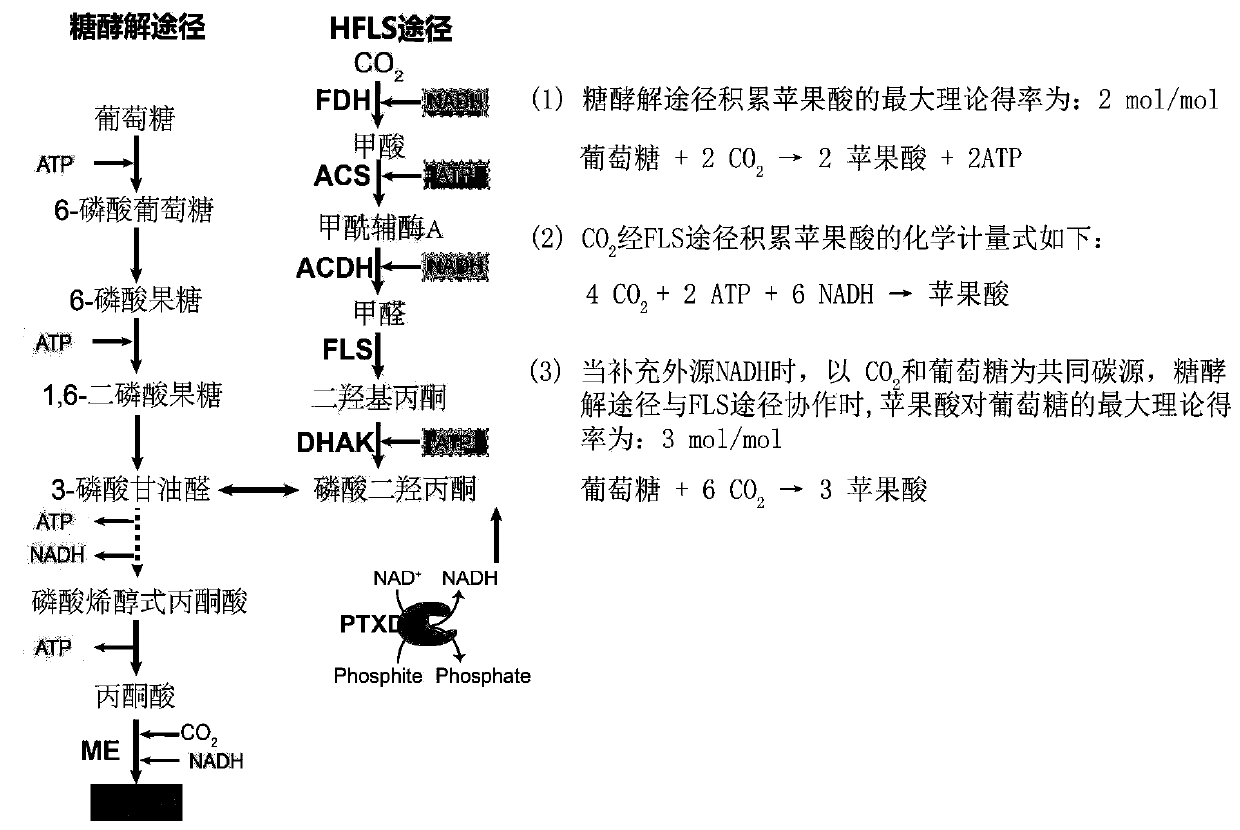

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Constructing a method capable of fixing CO 2 Escherichia coli engineered strain producing malic acid

[0042] (1) Knockout of fumarate reductase gene frdBC in E.coli MG1655

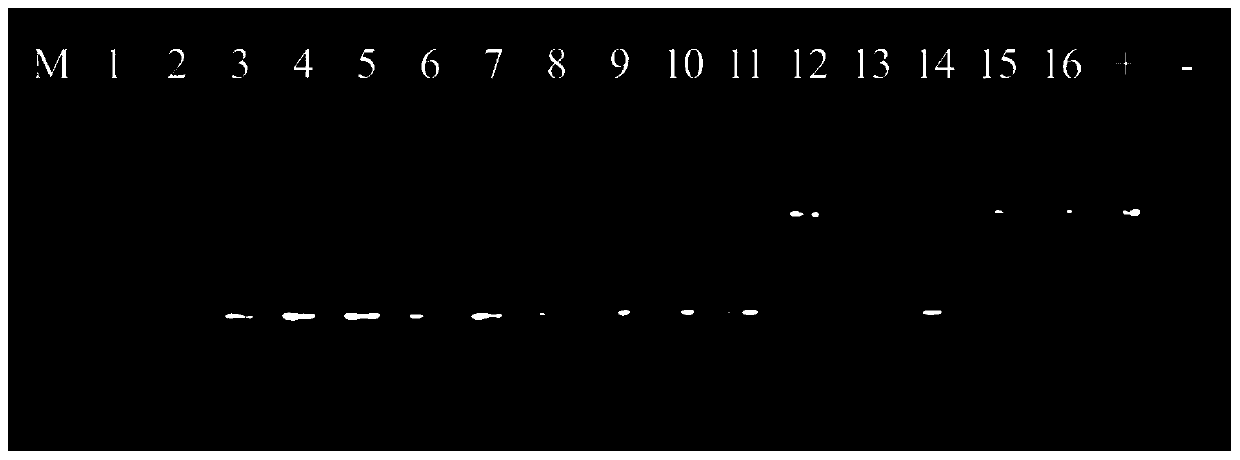

[0043] Knockout primers QCfrdBC-S and QCfrdBC-A were designed according to the frdBC gene sequence of Escherichia coli MG1655 in the NCBI database (Table 1), and the frdBC knockout frame was amplified using the pKD4 plasmid as a template and gel recovery was performed.

[0044] Remarks: The pKD4 plasmid contains two FRT sites (which can be folded under the action of flippase to eliminate the DNA sequence between the FRT sites), and between the two FRT sites is kanamycin (kan, used as a gene knockout screening pressure), the gene encoding FRT-kan-FRT. When the gene is knocked out, the primers are designed to amplify the DNA fragment of FRT-kan-FRT. It should be pointed out that the designed two amplification primers respectively contain the upstream and downstream 39-49bp of the target...

Embodiment 2

[0068] Example 2: Fermentative production of malic acid by engineering Escherichia coli GH0402 and GH0407

[0069] Plate activation medium and activation culture conditions: plate activation medium is LB medium, activation conditions: 37 ° C incubator inverted for 12 hours.

[0070] The fermentation medium used for fermentation contains: glucose 50g / L, Na 2 HPO 3 ·5H 2 O 20mM, KHCO 3 50mM, Na 2 HPO 4 12H 2 O 15.11g / L, KH 2 PO 4 3g / L NH 4 Cl 1g / L, NaCl 0.5g / L, trace element solution 1mL / L; trace element solution: FeCl 3 ·6H 2 O 2.4g / L, CoCl 2 ·6H 2 O 0.3g / L, CuCl 2 0.15g / L, ZnCl 2 4H 2 O 0.3g / L, NaMnO 4 0.3g / L, H 3 BO 3 0.075g / L, MnCl 2 4H 2 O 0.495g / L, with 0.1M HCl as solvent.

[0071] After activating the engineered Escherichia coli GH0402 and GH0407 on the plate, pick a single colony in the liquid LB seed medium, and cultivate it at 37°C and 200rpm for 12h (OD 600 =3-4). After the seed culture is completed, inoculate it into the fermentation medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com