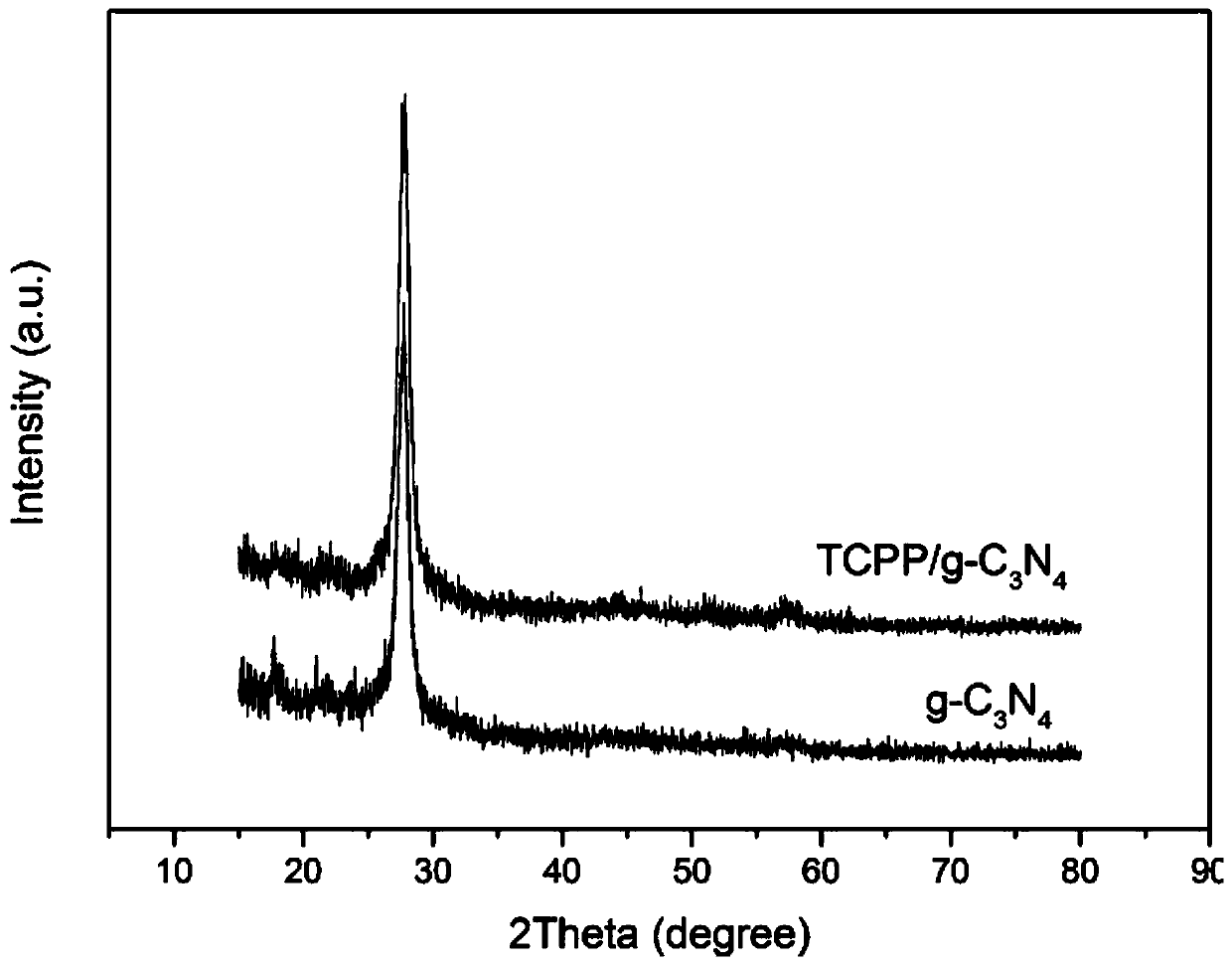

Preparation method of porphyrin/carbon nitride layer-by-layer composite structure photocatalytic nano-composite material

A nanocomposite material and composite structure technology are applied in the field of preparation of porphyrin/carbon nitride layer-by-layer composite structure photocatalytic nanocomposite materials, and can solve the problem that the increase of carbon nitride specific surface area and the carbon nitride charge transport cannot be achieved at the same time. and separation efficiency increase, to achieve the effects of excellent charge transport and separation efficiency, inhibition of recombination, and increase of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a porphyrin / carbon nitride layer-by-layer composite structure photocatalytic nanocomposite material, comprising the following steps:

[0026]Step 1: Take 1g of melamine and dissolve melamine and glycerol phosphatidylcholine in 60ml of deionized water at a molar ratio of melamine and glycerol phosphatidylcholine of 1:1.38, then keep stirring for 15 minutes until completely dissolved to obtain a mixed solution; then mix The solution was placed in a polytetrafluoroethylene-lined hydrothermal kettle, hydrothermally reacted at 180°C for 10 hours, and then centrifuged. After centrifugation, it was washed 3 times with deionized water and dried at 60°C for 12 hours to obtain a solid;

[0027] Step 2: Add 0.02g of KOH to the solid to obtain a solid mixture; then take carbon fiber according to the mass ratio of solid to carbon fiber 0.01:1 and mechanically mix it with the solid mixture as raw material, place it in a 500mL corundum crucible and cover it , a...

Embodiment 2

[0031] A preparation method of a porphyrin / carbon nitride layer-by-layer composite structure photocatalytic nanocomposite material, comprising the following steps:

[0032] Step 1: Take 1g of melamine and dissolve melamine and glycerol phosphatidylcholine in 80ml of deionized water at a molar ratio of melamine and glycerol phosphatidylcholine of 1:1.58, then keep stirring for 30min until completely dissolved to obtain a mixed solution; then mix The solution was placed in a polytetrafluoroethylene-lined hydrothermal kettle, hydrothermally reacted at 200°C for 15 hours, and then centrifuged. After centrifugation, it was washed 4 times with deionized water and dried at 70°C for 11 hours to obtain a solid;

[0033] Step 2: Add 0.05g of KOH to the solid to obtain a solid mixture; then take carbon fiber according to the mass ratio of solid to carbon fiber 0.018:1 and mechanically mix it with the solid mixture as a raw material, then place it in a 500mL corundum crucible and cover it ...

Embodiment 3

[0039] A preparation method of a porphyrin / carbon nitride layer-by-layer composite structure photocatalytic nanocomposite material, comprising the following steps:

[0040] Step 1: Take 1g of melamine and dissolve melamine and glycerol phosphatidylcholine in 120ml of deionized water at a molar ratio of 1:2.56 to melamine and glycerol phosphatidylcholine, then keep stirring for 60min until completely dissolved to obtain a mixed solution; then mix The solution was placed in a polytetrafluoroethylene-lined hydrothermal kettle, subjected to a hydrothermal reaction at 240°C for 24 hours, and then centrifuged. After centrifugation, it was washed 5 times with deionized water and dried at 100°C for 10 hours to obtain a solid;

[0041] Step 2: Add 0.1g of KOH to the solid to obtain a solid mixture; then take carbon fiber according to the mass ratio of solid to carbon fiber 0.025:1 and mechanically mix it with the solid mixture as raw material, then place it in a 500mL corundum crucible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com