Spraying type castor oil-based polyurethane damping material and preparation method thereof

A damping material, castor oil-based technology, applied in the field of spray castor oil-based polyurethane damping material and preparation, can solve the problem of insufficient crosslinking degree and compatibility of polyurethane molecules, insufficient strength and damping performance of elastomers, and lower product quality. Density and other issues, to achieve the effects of microphase separation, fast curing speed, and improved hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

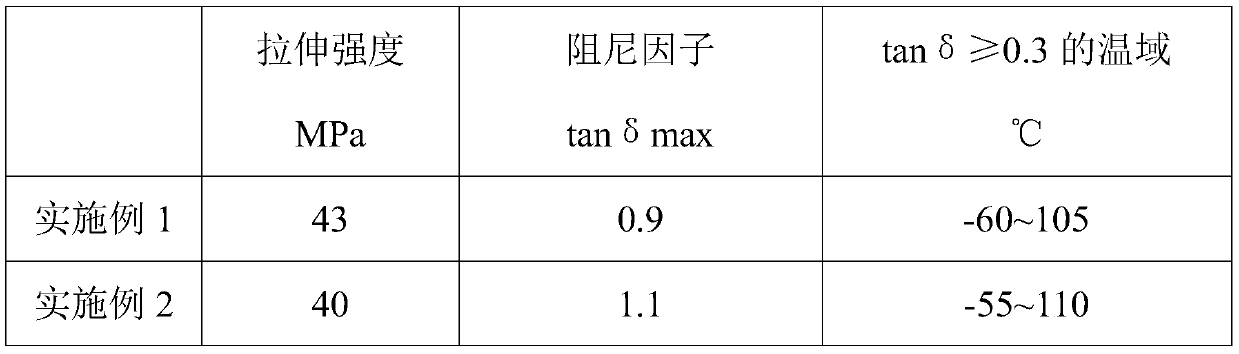

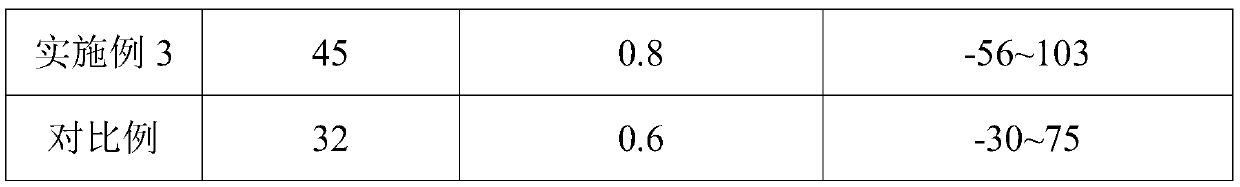

Examples

Embodiment 1

[0029] A spray-on castor oil-based polyurethane damping material, which is obtained by reaction polymerization of component A and component B according to the mass ratio of 1:2;

[0030] Component A is made of the following raw materials in parts by mass: 500 parts of castor oil, 2000300 parts of polytetrahydrofuran diol, 470 parts of toluene diisocyanate, 20 parts of p-phenylene diisocyanate MDI-5020 parts, 20 parts of dimethylol propionic acid , 15 parts of γ-aminopropyltriethoxysilane, 300 parts of dibutyl phthalate; wherein, the hydroxyl functionality of castor oil is 2.7, and the molecular weight is 931; the functionality of polytetrahydrofuran diol 2000 is 2;

[0031] Component B is composed of the following raw materials in parts by weight: 2000450 parts of amino-terminated polyether, 25 parts of vulcanizing agent MOCA, 360 parts of dioctyl phthalate, 200 parts of mica, 10102 parts of antioxidant, fumed silica 15 parts; wherein, the functionality of the amino-terminate...

Embodiment 2

[0038] A spray-on castor oil-based polyurethane damping material, which is obtained by reaction polymerization of component A and component B according to the mass ratio of 1:2;

[0039] Component A is made of the following raw materials in parts by mass: 600 parts of castor oil, 2000200 parts of polytetrahydrofuran diol, 500 parts of p-phenylene diisocyanate MDI-50500 parts, 80 parts of toluene diisocyanate, 15 parts of dimethylol propionic acid , 20 parts of γ-aminopropyltriethoxysilane, 200 parts of chlorinated palm oil methyl ester; wherein, the hydroxyl functionality of castor oil is 2.7, and the molecular weight is 931; the functionality of polytetrahydrofuran diol 2000 is 2;

[0040] Component B is composed of the following raw materials in parts by weight: 3,000,500 parts of amino-terminated polyether, 15 parts of vulcanizing agent MOCA, 52,200 parts of chlorinated paraffin, 200 parts of graphite, 10,102 parts of antioxidant, and 15 parts of fumed silica; The amino pol...

Embodiment 3

[0047] A spray-on castor oil-based polyurethane damping material, which is obtained by reaction polymerization of component A and component B according to the mass ratio of 1:3;

[0048] Component A is made of the following raw materials in parts by mass: 650 parts of castor oil, 3000200 parts of polytetrahydrofuran diol, 600 parts of toluene diisocyanate, 100 parts of isophorone diisocyanate, 30 parts of neopentyl glycol, γ- 15 parts of aminopropyltriethoxysilane, 200 parts of triphenyl phosphate; wherein, the hydroxyl functionality of castor oil is 2.7, and the molecular weight is 931; the functionality of polytetrahydrofuran diol 3000 is 2;

[0049] Component B is composed of the following raw materials in parts by weight: 1,000,100 parts of amino-terminated polyether, 3,000,300 parts of amino-terminated polyether, 20 parts of vulcanizing agent MOCA, 250 parts of dibutyl phthalate, 300 parts of mica, antioxidant 10352 parts of agent, 20 parts of fumed silica; wherein, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com