Preparation method and application of metal organic framework (MOF)-derived magnetic porous carbon material

A porous carbon material and magnetic technology, applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of limited application, easy collapse, etc., achieve good stability, increase ratio The best surface area and adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides the preparation method of MOFs derived magnetic porous carbon material MPCK, including the following steps: Weigh 3.2 gFeCl 3 •6H 2 O and 1.0 g of PTA were dissolved in 70 mL of DMF, and after complete dissolution, they were transferred to a 100 mL hydrothermal reaction synthesis kettle, sealed and placed in an oven at 110 °C for 24 h. Cool to room temperature, wash with DMF and acetone, and dry under vacuum at 60 °C for 8 h to obtain orange solid MIL-101(Fe). Weigh 0.4 g KOH and 0.2 g MIL-101(Fe) into a porcelain boat, then put them into a high-temperature combustion tube furnace, carbonize at 700 °C for 4 h, let it cool naturally, and adjust with 0.1 mol / L HCl pH to neutral, and then washed with deionized water to obtain MOFs-derived magnetic porous carbon material MPCK.

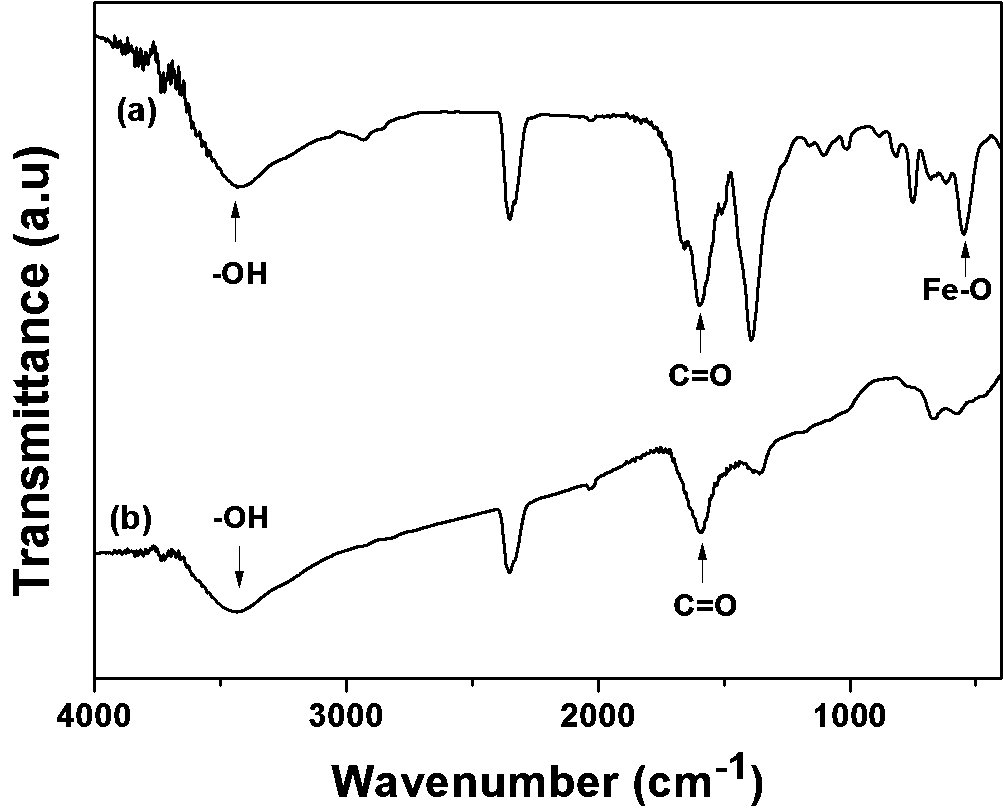

[0037] Below, the physical and chemical properties of MPCK are characterized by FT-IR and SEM.

[0038] Depend on figure 1 As shown in a, at 748 cm -1 The peak at is a...

Embodiment 2

[0041] In this embodiment, the method for preparing MOFs-derived magnetic porous carbon material MPCK using Example 1 includes the following steps:

[0042] The effect of the ratio of KOH solid to MIL-101(Fe) on the yield of MPCK was investigated.

[0043]MPCK was prepared according to the method described in Example 1, with the difference that the ratios of KOH solid to MIL-101(Fe) were 1:1, 2:1, and 3:1, respectively. As can be seen from the observation results, when the ratio is 1:1, MPCK is not completely carbonized; when the ratio is 3:1, the yield of MPCK drops significantly; when the ratio of KOH solid to MIL-101(Fe) is 2:1, The yield of MPCK is the largest and the carbonization is complete, so the ratio selected by the present invention is 2:1.

Embodiment 3

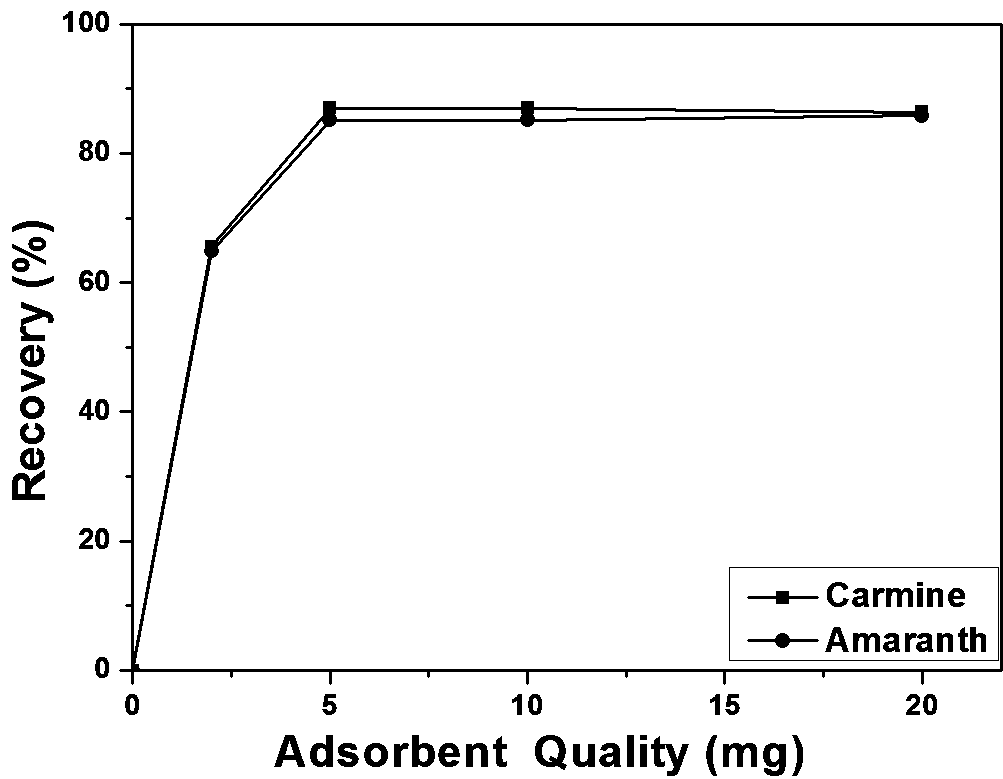

[0045] The present embodiment utilizes carmine and amaranth in the MPCK extraction aqueous solution that embodiment 1 prepares, comprises the following steps:

[0046] The influence of the quality of MPCK on the extraction efficiency was investigated.

[0047] Pipette 100 μL of the mixed standard with a concentration of 5 mg / L, add it into a brown sample bottle, and dilute to 10 mL with deionized aqueous solution with pH=7. The amount of MOFs-derived magnetic porous carbon material MPCK added is 3 mg, 5 mg, 10 mg, 20 mg, vortex extraction for 20 min, magnetic separation, discard the supernatant, add 3 mL (ammonia:methanol=2%:98%) eluent; vortex elution for 20 min, magnetic separation , the eluent was blown dry with nitrogen gas, fixed to volume with mobile phase, centrifuged at 12000 r / min for 10 min, and the supernatant was removed for chromatographic analysis. Depend on image 3 It can be seen that when the mass of the adsorbent reaches 5 mg, the extraction efficiency reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com