Environmentally-friendly and flame-retardant SBS modified asphalt coating material for waterproof roll, and preparation method thereof

A waterproof membrane and modified asphalt technology, applied in asphalt coatings, fireproof coatings, coatings, etc., can solve problems such as ignition of waterproof membranes or other flammable materials, large fire safety hazards, and burning of waterproof materials, etc., to achieve Fire-retardant, flame-retardant and smoke-suppressing, high seam peeling strength, and not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

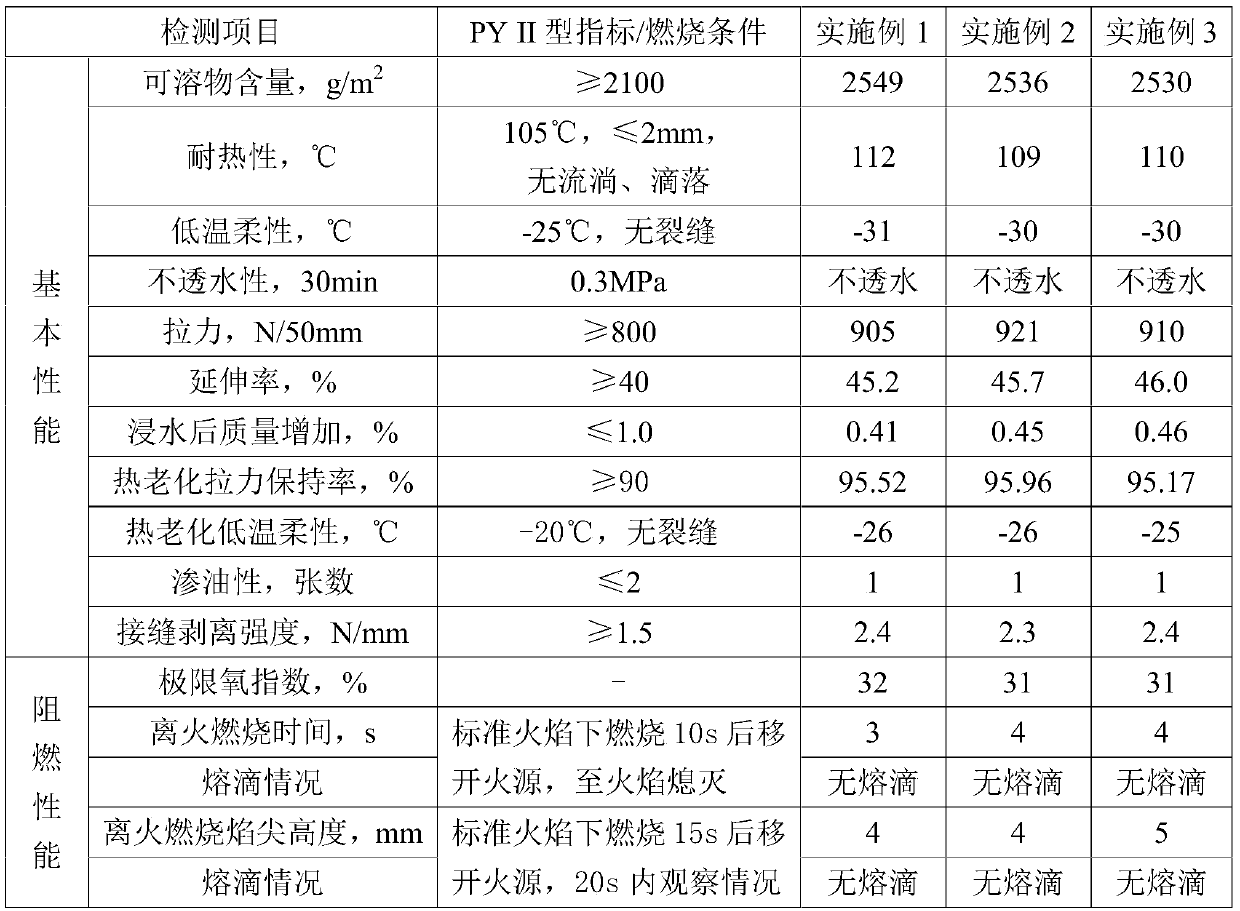

Examples

Embodiment 1

[0040] The waterproof coiled material of the present embodiment is made of the following raw materials in parts by weight: 100 parts of petroleum asphalt, 20 parts of naphthenic oil, 15 parts of SBS, 7 parts of SBR, 3.5 parts of nitrile rubber, 11 parts of talc, 10 parts of ammonium polyphosphate, 5.0 parts of melamine phosphate, 2.0 parts of zinc borate, 3.0 parts of organic montmorillonite, 7.0 parts of magnesium aluminum hydrotalcite, and 1.0 part of antioxidant.

[0041] The preparation method of the environmentally friendly flame-retardant SBS modified asphalt coating material for the waterproof coiled material of the present embodiment comprises the following steps:

[0042] 1) According to the mass ratio of sodium montmorillonite and cetyltrimethylammonium chloride being 1:0.4, take sodium montmorillonite and add cetyltrimethylchloride with a mass concentration of 4%. In an aqueous solution of ammonium chloride, heat to 75°C, stir for 3.5 hours to react, then separate s...

Embodiment 2

[0053] The waterproof coiled material of the present embodiment is made of the following raw materials in parts by weight: 100 parts of petroleum asphalt, 21 parts of naphthenic oil, 16 parts of SBS, 6 parts of SBR, 3.0 parts of nitrile rubber, 10 parts of talc, 11 parts of ammonium polyphosphate, 5.5 parts of melamine phosphate, 1.5 parts of zinc borate, 3.0 parts of organic montmorillonite, 7 parts of magnesium aluminum hydrotalcite, and 1.0 part of antioxidant.

[0054] The preparation method of the environmentally friendly flame-retardant SBS modified asphalt coating material for the waterproof coiled material of the present embodiment comprises the following steps:

[0055] 1) According to the mass ratio of sodium montmorillonite and cetyltrimethylammonium chloride being 1:0.4, take sodium montmorillonite and add cetyltrimethylchloride with a mass concentration of 4%. In ammonium chloride aqueous solution, heated to 75°C, stirred for 2.0 hours, then separated into solid a...

Embodiment 3

[0066] The environmental protection flame-retardant SBS modified asphalt coating material for the waterproof membrane of this embodiment is made of the following raw materials in parts by weight: 100 parts of petroleum asphalt, 19 parts of naphthenic oil, 14.5 parts of SBS, 8 parts of SBR, 4.0 parts of nitrile rubber, 10 parts of talc, 9 parts of ammonium polyphosphate, 4.5 parts of melamine phosphate, 2.0 parts of zinc borate, 4.0 parts of organic montmorillonite, 8 parts of magnesium aluminum hydrotalcite, and 1.0 part of antioxidant.

[0067] The preparation method of the environmentally friendly flame-retardant SBS modified asphalt coating material for the waterproof coiled material of the present embodiment comprises the following steps:

[0068] 1) According to the mass ratio of sodium montmorillonite and cetyltrimethylammonium chloride being 1:0.4, take sodium montmorillonite and add cetyltrimethylchloride with a mass concentration of 4%. In ammonium chloride aqueous so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com