Method for cooperative resourceful treatment of lead-zinc smelting slag and ferrous sulfate slag

A technology for smelting slag and jarosite slag is applied in the field of collaborative resource treatment of lead-zinc smelting slag and jarosite slag, which can solve the problems of dangerous solid waste accumulation of jarosite slag, high energy consumption of the treatment process, and serious environmental pollution. Achieve the effect of eliminating SO2 pollution, simple operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

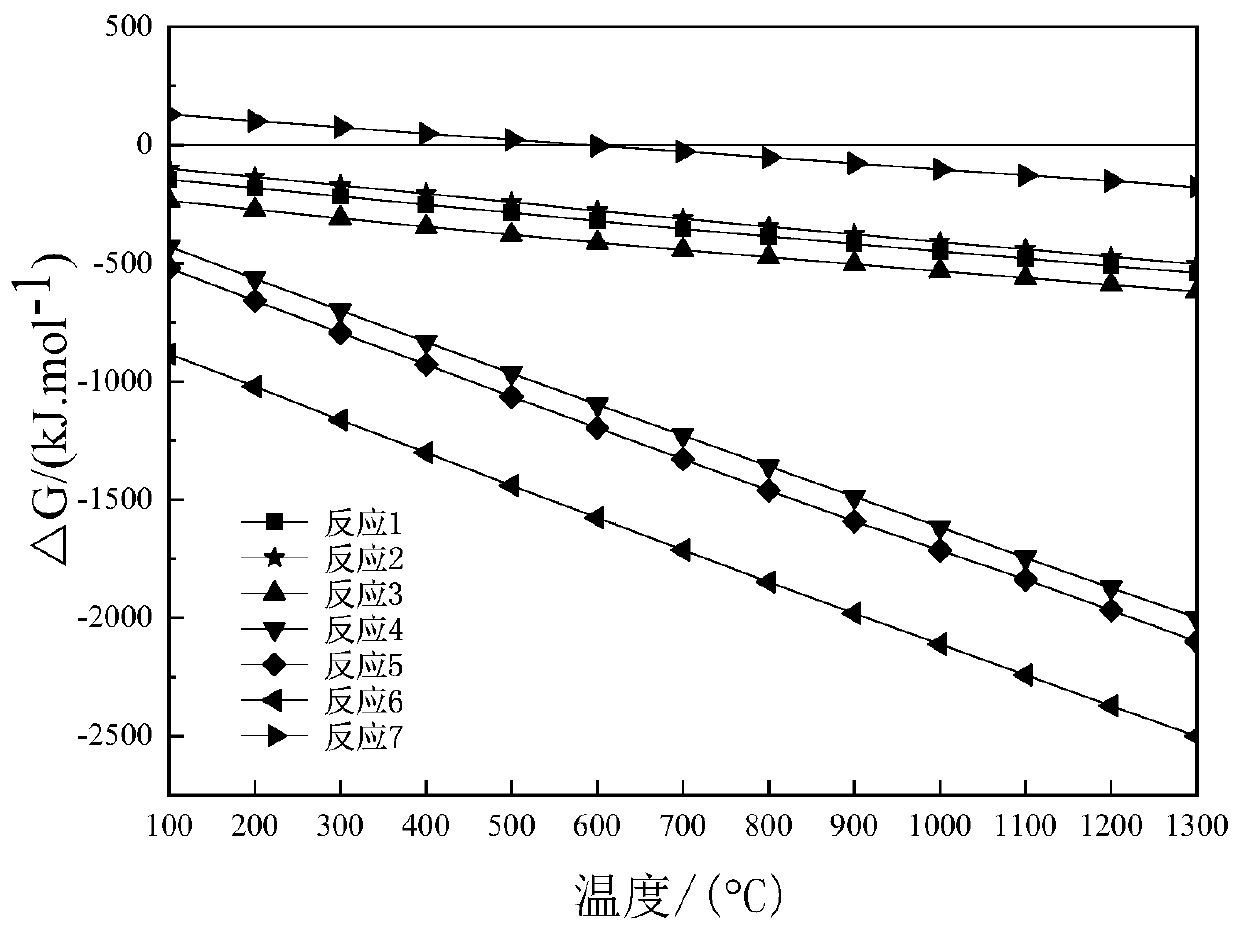

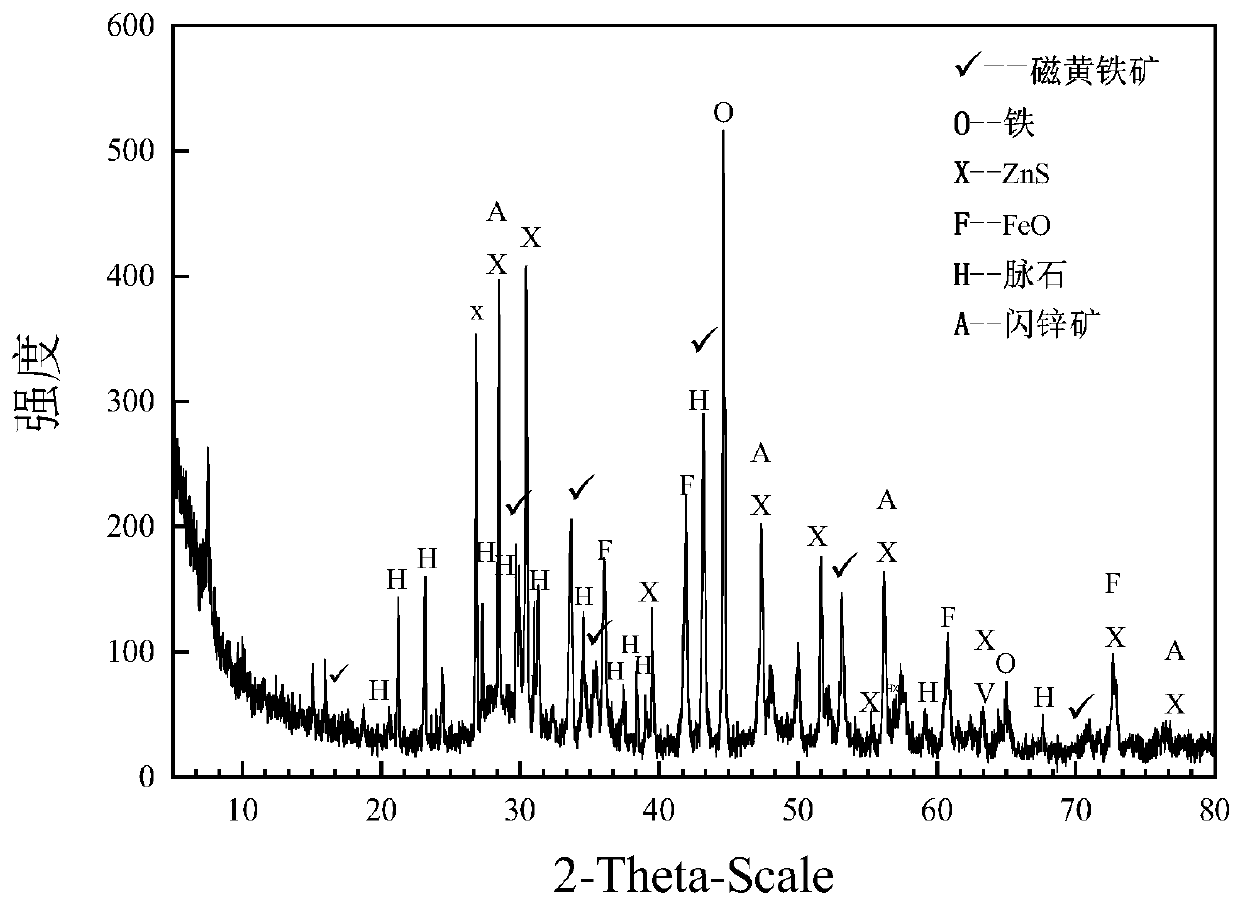

Method used

Image

Examples

Embodiment 1

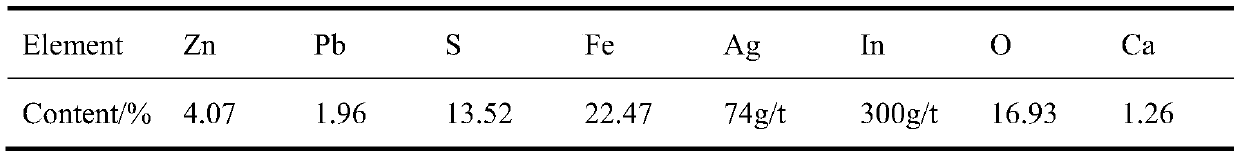

[0034] The iron-vanadium slag used in this embodiment is the jarosite slag produced by a certain zinc smelter in Chenzhou, and its specific components are shown in Table 1.

[0035] The main chemical composition / % of table 1 jarosite slag

[0036]

[0037] The zinc smelting slag used in this example is zinc smelting low-acid leaching slag, and its specific composition is shown in Table 2. 86% of the zinc in the zinc leaching slag exists in the form of zinc ferrite.

[0038] Table 2 Main chemical composition / % of zinc leaching slag

[0039]

[0040] A method for synergistically self-sulfiding roasting of auxinite slag and lead-zinc smelting slag, the specific steps are as follows:

[0041] (1) above-mentioned jarosite slag, zinc leach slag and the coke that particle size is 80% less than 5mm are mixed with mass ratio as 100:60:20;

[0042] (2) Take 150 kg of the above-mentioned mixed sample and place it in a self-made rotary kiln, pass nitrogen gas as a protective gas, ...

Embodiment 2

[0060] The vulcanizing agent used in this example is jarosite slag produced by a zinc smelter in Zhuzhou, and its specific chemical composition is shown in Table 5.

[0061] The main chemical composition / % of table 5 jarosite slag

[0062]

[0063] The steel mill zinc-containing smoke and dust used in this embodiment is the blast furnace dust produced by a certain steelmaking plant in Hunan. The particle size of the material is 75% less than 0.074mm. It exists with zinc ferrite, and iron exists in the form of ferric oxide, ferric silicate and ferric oxide.

[0064] Table 6 Main chemical components of soot from steel mills / %

[0065]

[0066] A method for synergistically self-sulfiding roasting of auxinite slag and lead-zinc smelting slag, the specific steps are as follows:

[0067] (1) above-mentioned jarosite slag, zinc leach slag and the coke that particle size is 80% less than 5mm are mixed with mass ratio as 100:75:40;

[0068] (2) Take 150 kg of the above-mention...

Embodiment 3

[0086] The jarosite slag and zinc ferrite slag used in this embodiment have specific chemical compositions shown in Table 5 and Table 2, respectively.

[0087] A method for synergistically self-sulfiding roasting of auxinite slag and lead-zinc smelting slag, the specific steps are as follows:

[0088] (1) above-mentioned jarosite slag, zinc leach slag and the coke that particle size is 80% less than 5mm are mixed with mass ratio as 100:80:40;

[0089] (2) Take 150 kg of the above-mentioned mixed sample and place it in a self-made rotary kiln, feed nitrogen gas as a protective gas, and roast at 1000 ° C for 120 min.

[0090] (3) Slowly cool and crystallize the calcined product at a cooling rate of 5°C / min, and cool down to room temperature naturally after dropping to 500°C.

[0091] (4) Sampling and analyzing the content of lead, zinc sulfide and iron in the roasted sample, and calculating the sulfur fixation rate, the sulfurization rate of lead and zinc and the reduction rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Crystal size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com