Ion source, ion injection device and ion source operation method

An ion source and ion technology, applied in the field of ion sources, can solve problems such as poor production efficiency, lower yield, vacuum pump failure, etc., and achieve the effect of changing maintenance cycle, decreasing resistance value, and long maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

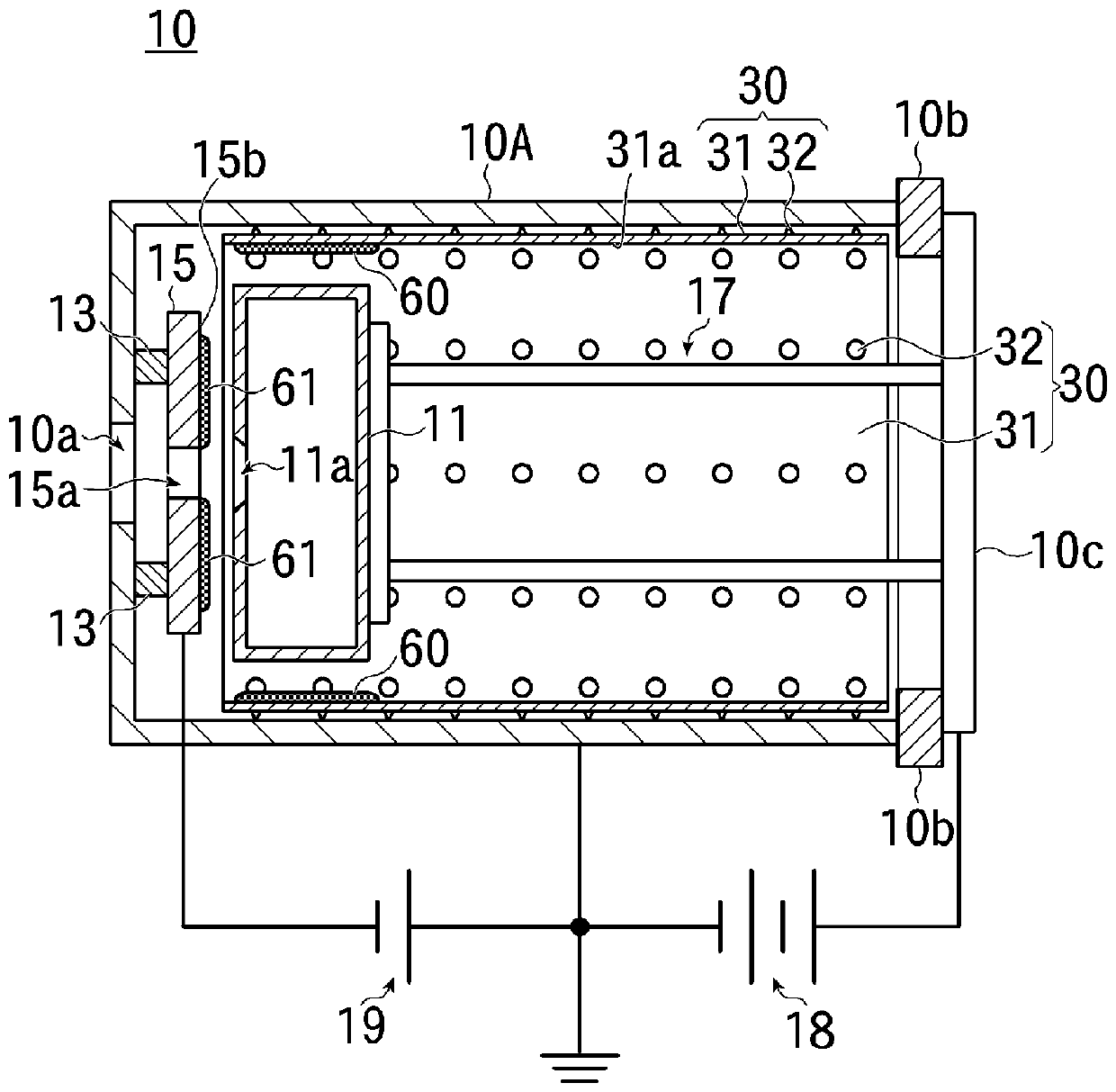

[0045] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

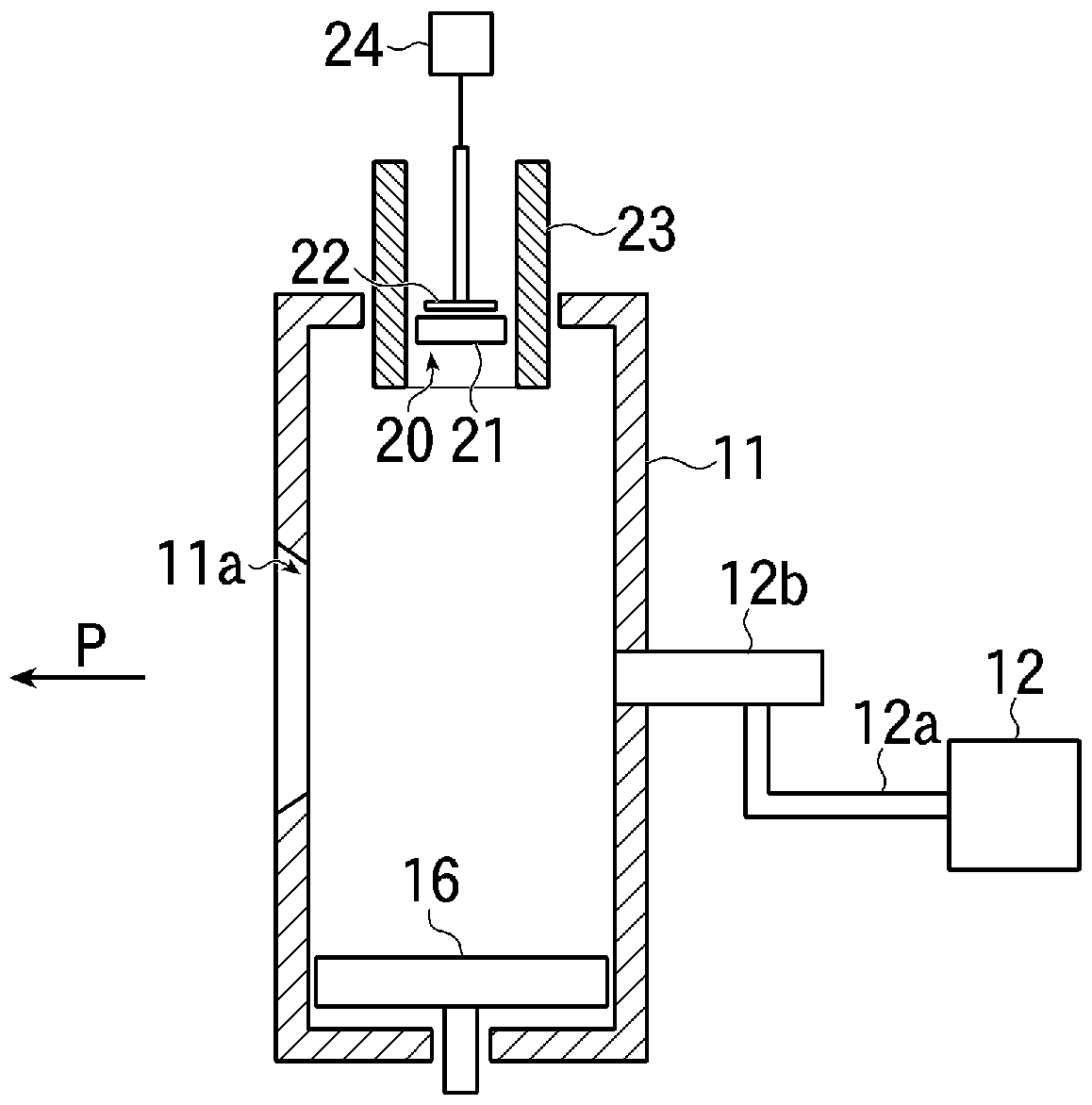

[0046] figure 1 It is a schematic configuration diagram showing the whole of an ion implantation apparatus using the ion source of the present invention.

[0047] Such as figure 1 As shown, ion source 10 , traveling chamber 2 , mass spectrometer 3 , accelerator 4 , scanning device 5 , and implantation chamber 6 described later are sequentially connected to constitute ion implantation apparatus 1 of this example.

[0048] Furthermore, this ion implantation apparatus 1 is configured such that the ion source 10 , the traveling chamber 2 , the acceleration device 4 , and the implantation chamber 6 are evacuated by vacuum evacuation devices 9 a to 9 d , respectively.

[0049] A gas supply unit 12 described later is connected to the ion source 10 , the gas supplied by the gas supply unit 12 is ionized, and the generated ions are made to travel inside the traveling chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com