Lactobacillus plantarum effect of preventing and treating decayed teeth

A Lactobacillus plantarum, dental caries technology, applied in the field of microorganisms, can solve the problems of weakening, inability to resist plaque, tooth pigmentation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

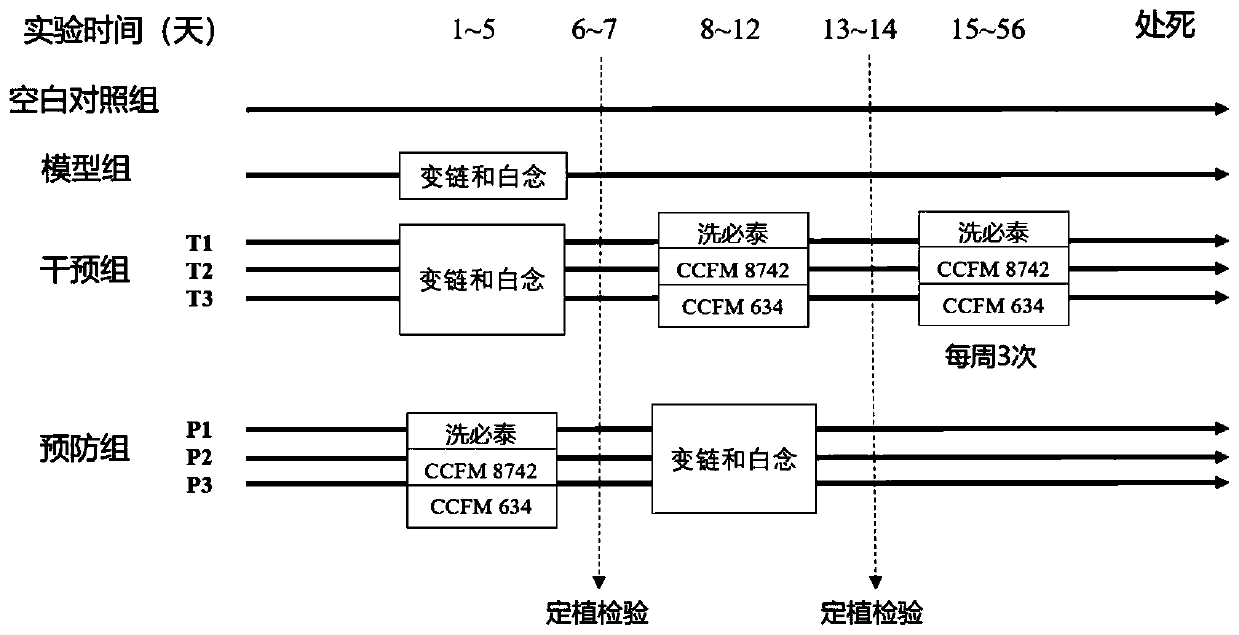

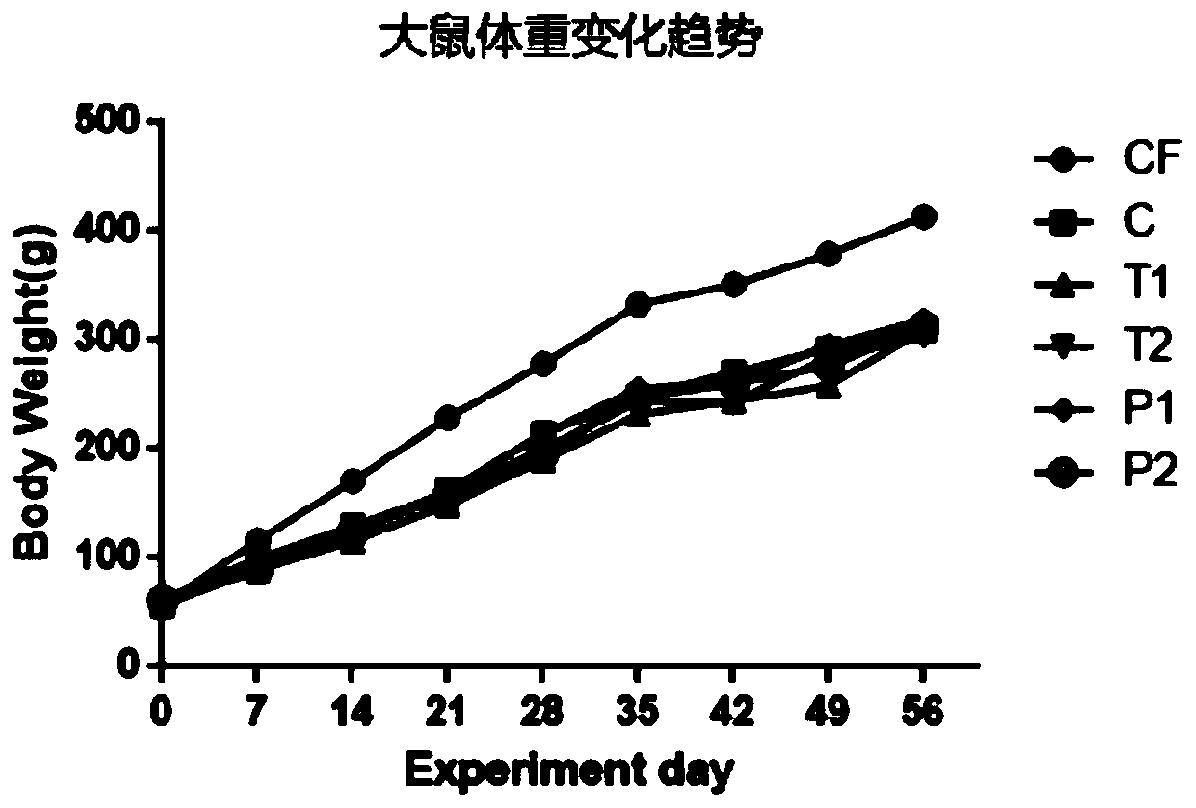

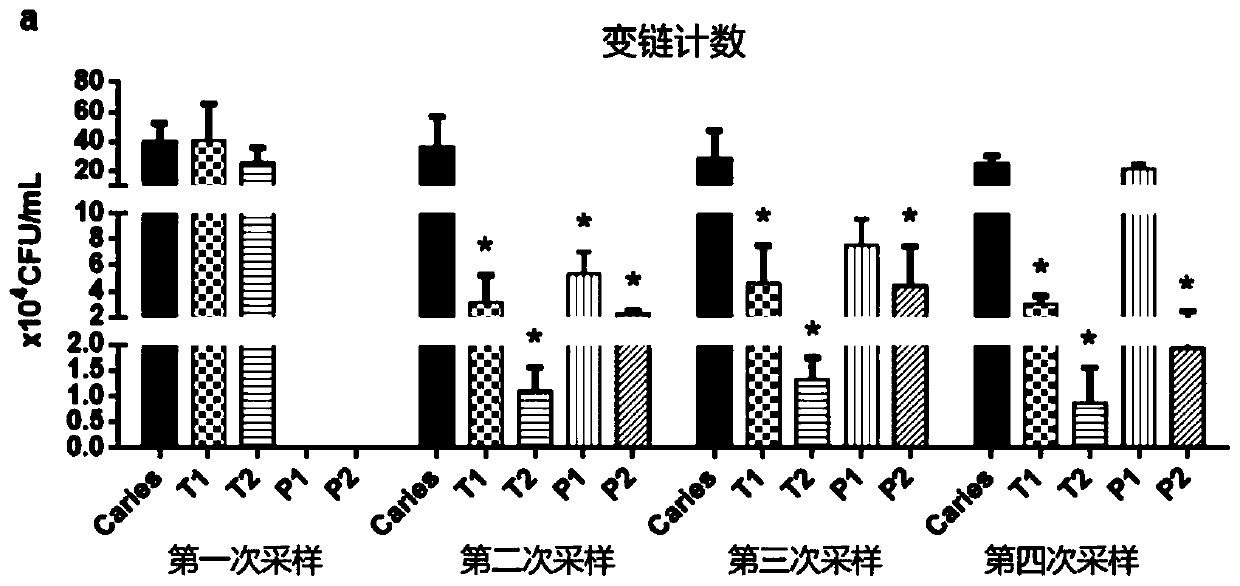

[0043] Example 1 Animal experiments on the use of Lactobacillus plantarum CCFM8724 in the prevention and treatment of dental caries

[0044] Experimental animals and strains:

[0045] SPF-grade Wistar rats, male, 3 weeks old, weighing 40-50 g, were purchased from Beijing Weitong Lihua Experimental Animal Technology Co., Ltd. (production license number SCXK (Beijing) 2012-0001).

[0046] Streptococcus mutans was Streptococcus mutans ATCC 25175, which was purchased from CGMCC, China General Microorganism Collection Center. Candida albicans was isolated from the oral cavity of volunteers.

[0047] Lactobacillus plantarum CCFM634 (CGMCC No.9740), as another strain of Lactobacillus plantarum with a better effect of inhibiting bibacterial biofilm in vitro (24h-mediated inhibition of biofilm amount> 60%), was also used in animal experiments for comparison. For the experiment of inhibiting the biofilm of double bacteria, the mediation group was to add 50 μL of Streptococcus mutans a...

Embodiment 2

[0088] Embodiment 2 prepares the bacteria powder containing Lactobacillus plantarum CCFM8724 live bacteria

[0089] Lactobacillus plantarum CCFM8724 was added to the MRS liquid fermenter with 10% inoculum and cultivated for 12 hours, the pH of the fermentation process was controlled to 5.4-5.8, the fermentation was terminated and the temperature was lowered to below 20°C, and the bacteria were collected by centrifugal equipment. Add lyoprotectant (4% glycerin, 25% skimmed milk powder, 4% ascorbic acid, 1.5% sodium carbonate) at 1:1 ratio, and directly add the protective agent to the bacteria sludge to balance the emulsification, and the emulsification time is 30 minutes. The emulsion added with the bacteria slime was placed in a freeze dryer at -40°C and 4Pa for 48 hours, and the freeze-dried product was subjected to low-intensity crushing and sieving to obtain a high-activity probiotic freeze-dried powder.

Embodiment 3

[0090] Embodiment 3 prepares the yogurt containing Lactobacillus plantarum CCFM8724 live bacteria

[0091] Milk powder, inulin, stevia, and water are mixed according to the weight ratio: 20:5:5:75, homogenized, and made into fermentation raw materials; sterilized by ultra-high temperature sterilization at 121°C for 300s, then cooled to 42°C, inoculated and fermented Bacteria Lactobacillus bulgaricus and Streptococcus thermophilus mixed bacteria powder, the inoculation amount of fermentation bacteria is 0.3% of the total weight of fermentation raw materials; after 12 hours of fermentation at 42°C, it is prepared; the fermentation product is cooled to 37°C, and Lactobacillus plantarum CCFM8724 is added Freeze-dried bacteria powder, the feeding amount is 10 9 CFU / ml yogurt, stirred, canned, stored at 4°C for 2 days and naturally cooked to make probiotic yogurt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com