A kind of nerve injury repair material and its preparation method and application

A technology for nerve injury and repair materials, which is applied in the field of medical devices, can solve the problems of non-conductivity, insufficient mechanical strength, and rapid degradation, etc., and achieve the effect of increasing electrical conductivity, simple and feasible preparation process, and improving degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, preparation and performance testing of nerve guide

[0045] 1. Preparation of nerve guide

[0046] 1. Preparation of materials for nerve guides

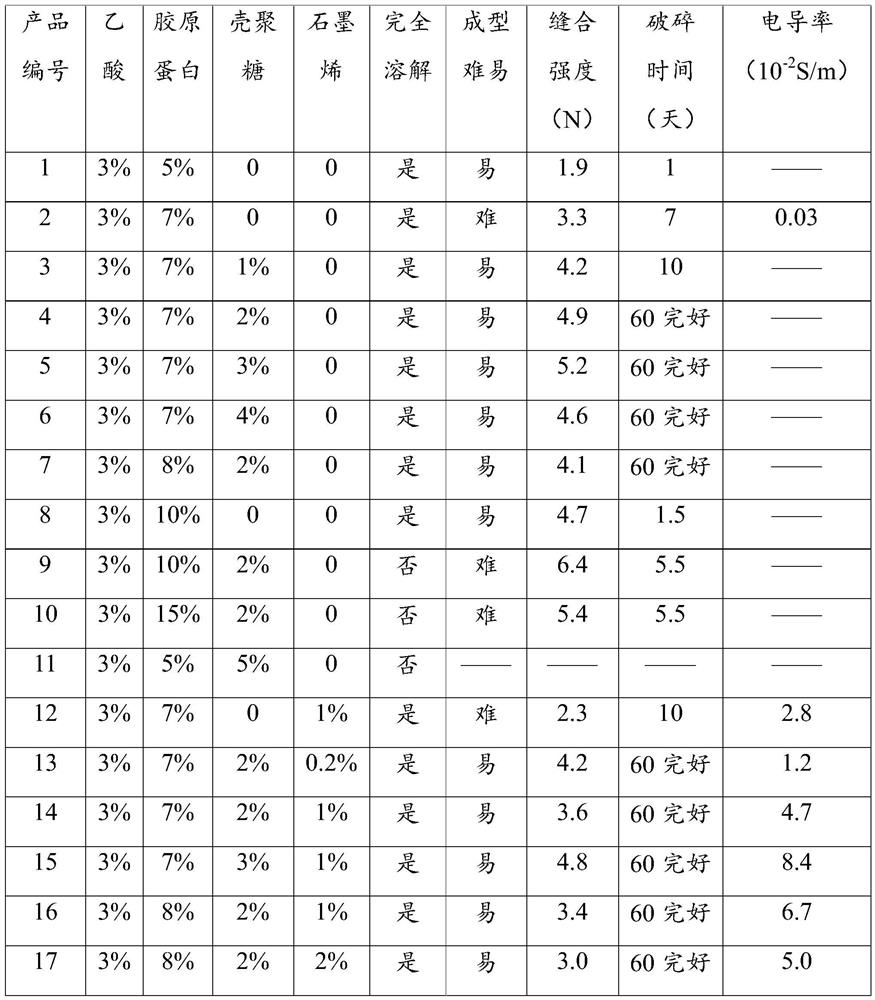

[0047] Get collagen, chitosan, acetic acid aqueous solution (acetic acid concentration is 3%) and graphene and mix according to the concentration shown in Table 1, obtain mixed slurry. "%" in Table 1 represents g / 100mL.

[0048] 2. Inject into the mold

[0049] Take the 17 kinds of mixed slurries obtained in step 1 and inject them into hollow stainless steel cylindrical molds (diameter 6mm, length 30mm), then insert a central axis with a diameter of 4mm into the center of the mold, and then install fixing caps at both ends of the mold to fix the central axis.

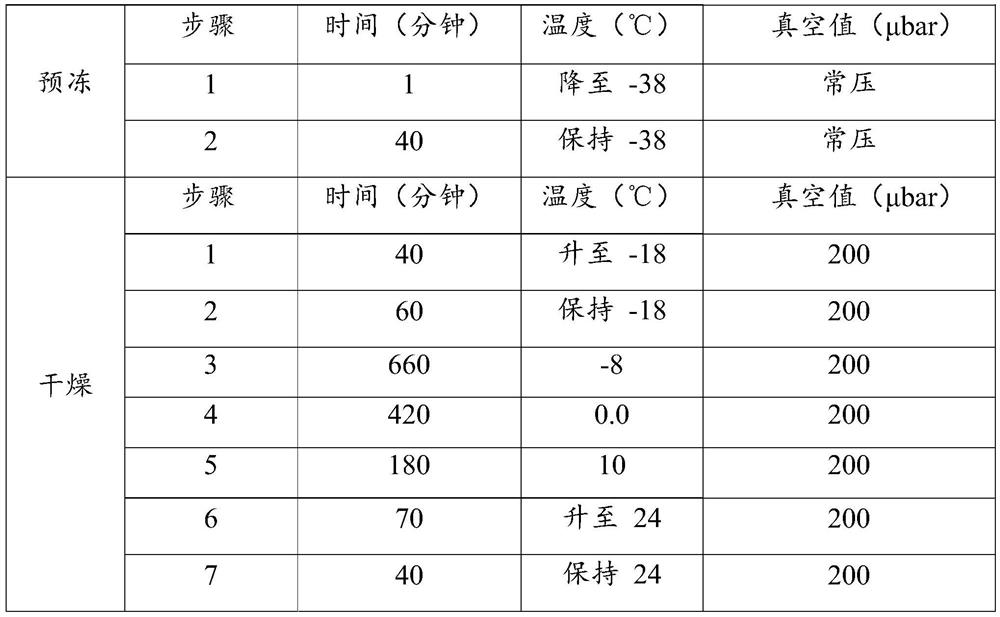

[0050] 3. Freeze drying

[0051]1) Gradient freeze-drying: put the mold in step 2 in the elevator, the descending speed is 10 rpm, the angle is adjusted to 9, and the time interval is 1.5s. Maintain for 40 minutes, thaw for 2 hours in the freezer at -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com