Method for realizing zero discharge and resource utilization of reverse osmosis concentrated water in coal chemical industry

A reverse osmosis concentrated water, zero-discharge technology, applied in chemical instruments and methods, oxidized water/sewage treatment, inorganic chemistry, etc., can solve the problems of secondary pollution, high energy consumption, low treatment efficiency, etc., to reduce treatment costs. , the effect of high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

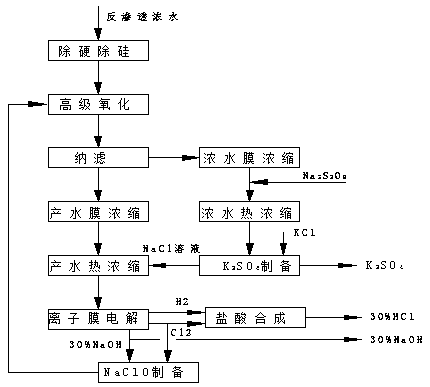

Image

Examples

Embodiment 1

[0033] The reverse osmosis concentrated water of a coal chemical water treatment unit is shown in Table 1 and processed through the following steps:

[0034] Table 1 Coal chemical reverse osmosis concentrated water indicators

[0035] project Ca Mg SiO2 COD TOC TDS Cl- SO4 2-

Value, mg / L 120 40 80 195 65 22000 7100 13200

[0036] (1) The reverse osmosis concentrated water first enters the hard and silicon removal unit, and then add softening agent and silicon removing agent. The softening agent is calcium hydroxide, sodium carbonate and magnesium oxide. L, Mg: 5mg / L, SiO 2 : 10mg / L.

[0037] (2) The effluent from step 1 enters the advanced oxidation unit to remove organic matter, and uses NaClO in the NaClO preparation unit to oxidize and remove organic matter in the wastewater. Dosing NaClO according to m(NaClO):m(COD)=2, the effluent COD is reduced to 92mg / L.

[0038] (3) The effluent from step 2 enters the nanofiltration un...

Embodiment 2

[0048] The reverse osmosis concentrated water of a coal chemical water treatment unit is shown in Table 1 and processed through the following steps:

[0049] Table 1 Coal chemical reverse osmosis concentrated water indicators

[0050] project Ca Mg SiO 2

COD TOC TDS Cl- SO4 2-

Value, mg / L 110 60 90 240 80 25600 16100 8100

[0051] (1) The reverse osmosis concentrated water first enters the hard and silicon removal unit, and then add softening agent and silicon removing agent. The softening agent is calcium hydroxide, sodium carbonate and magnesium oxide, and the Ca of the hard and silicon removing unit: 6mg / L, Mg: 4mg / L, SiO 2 : 12mg / L.

[0052] (2) The effluent from step 1 enters the advanced oxidation unit to remove organic matter, and uses NaClO in the NaClO preparation unit to oxidize and remove organic matter in the wastewater. Dosing NaClO according to m(NaClO):m(COD)=2, the effluent COD is reduced to 125mg / L.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com