Device and method for recycling aluminum etching solution

An aluminum etching and material liquid technology, applied in the field of electronic chemicals, can solve the environmental impact of waste discharge, ethanol residue in phosphoric acid, reduce the concentration of phosphoric acid, etc., to simplify the recycling process, improve the quality concentration and purity, Effect of Simplified Recycling Process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

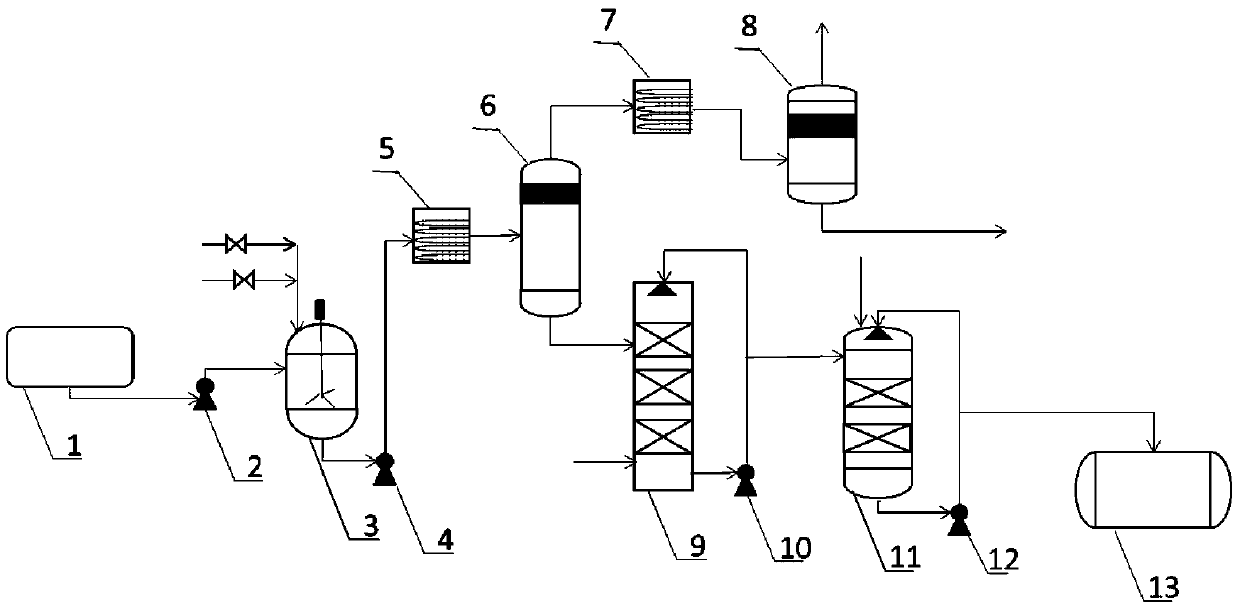

[0031] Such as figure 1 As shown, a device for recovering and reusing aluminum etching solution includes a waste acid storage tank 1, which is connected to a reactor 3 feed line, and the reactor 3 is also connected to a phosphorus pentoxide feed pipeline; the reactor 3 outlet Connected to the evaporator 5, the outlet of the evaporator is connected to the evaporation separator 6, the gas outlet of the evaporation separator is connected to the exhaust gas condenser 7 and the exhaust gas separator 8 in turn, and the liquid outlet of the evaporation separator is connected to the phosphoric acid stripping tower 9, Then connect the phosphoric acid mixing tank 11 and the phosphoric acid storage tank 13 in sequence; the lower part of the phosphoric acid stripping tower is provided with a nitrogen inlet pipe.

[0032] In a preferred solution, a jacketed heat exchanger is arranged outside the reactor. In another preferred solution, a nitrogen feed line is also arranged on the phosphoru...

Embodiment 2

[0039] The method for recycling the aluminum etching solution by using the above-mentioned device comprises the following steps:

[0040](1) The aluminum etching solution in the waste acid storage tank is fed into the reactor, and reacts with phosphorus pentoxide to increase the concentration of phosphoric acid in the mixed acid to 86% to 88%, and it is added through the high-purity nitrogen gas on the phosphorus pentoxide pipeline For the pipeline, the nitrogen pressure is controlled at 10kpa to 20kpa, and the phosphorus pentoxide is dispersed and protected by nitrogen sealing;

[0041] (2) After the reaction, the mixed acid is transported to the evaporator to heat up, and the temperature is controlled at 80°C to 85°C. The heated mixed acid enters the evaporator separator in a negative pressure state for gas-liquid separation. The negative pressure is -0.15Mpa, and the gaseous nitric acid and Acetic acid enters the exhaust gas condenser from the top of the gas-liquid separato...

Embodiment 3

[0045] Carry out the method for recycling aluminum etching solution with device among the embodiment 1, may further comprise the steps:

[0046] (1) The aluminum etching solution in the waste acid storage tank is fed into the reactor, and reacts with phosphorus pentoxide to increase the concentration of phosphoric acid in the mixed acid to 80% to 83%, and it is added through the high-purity nitrogen gas on the phosphorus pentoxide pipeline Pipeline, disperse phosphorus pentoxide and protect it with nitrogen blanketing;

[0047] (2) After the reaction, the mixed acid is transported to the evaporator to heat up, and the temperature is controlled at 90°C to 95°C. The heated mixed acid enters the evaporator separator in a negative pressure state for gas-liquid separation. The negative pressure is -0.05Mpa, and the gaseous nitric acid and Acetic acid enters the exhaust gas condenser from the top of the gas-liquid separator, cools to 60°C and becomes liquid, enters the mixed acid st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com