Preparation method of N-type passivation contact solar cell

A solar cell, N-type technology, applied in the field of solar cells, can solve problems affecting cell efficiency and yield, and achieve the effects of reducing damage, avoiding bad appearance, and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation method of N-type passivation contact solar cell of the present invention, the technical scheme of its preparation comprises the following steps:

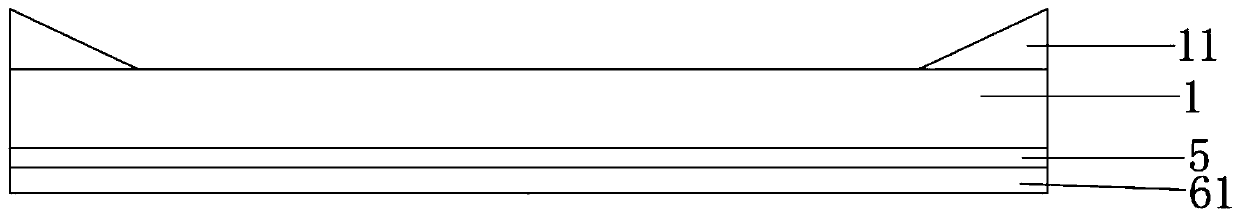

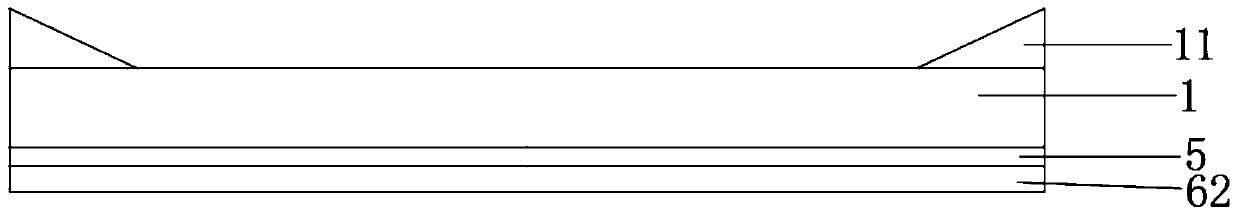

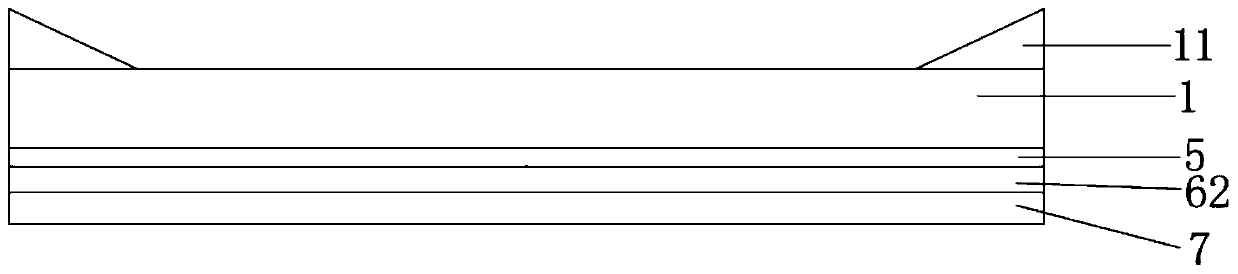

[0043] (1) Select an N-type crystalline silicon substrate 1, and perform polishing treatment on both sides of the N-type crystalline silicon substrate 1; wherein, the N-type crystalline silicon substrate 1 has a resistivity of 3Ω·cm and a thickness of 160 μm;

[0044] (2) On the N-type crystalline silicon substrate 1 treated in step (1), an ultra-thin tunneling oxide layer 5 is grown on its back surface; A layer of intrinsic amorphous silicon layer 61 containing a microcrystalline phase is deposited on the upper surface, and part of the amorphous silicon is wrapped around the front surface to form a polysilicon wrapped coating 11; wherein, the composition of the tunneling oxide layer 5 is silicon dioxide, and its preparation method is High-temperature thermal oxidation method, the thickness of the tunnel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com